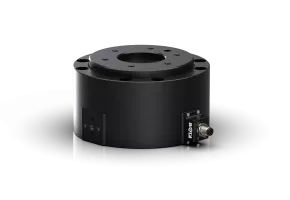

SCHUNK NSR-A Specifications

Ranked Nr. 38 of 116 End of Arm Tools

Pneumatic pallet change system with patented locking system.

| Type |

|

| Repeatability | 0 mm |

| Extra info | Time saving through automatic pallet changing / Very compact design for space-saving exchange and direct coupling on the machine table / Form-fit patented locking system with self-retention and high locking force / All functional components made from hardened steel for high mechanical resilience of the changing system / Integrated piston stroke monitoring and tool presence sensing for condition monitoring / Wide product line of electric and fluid modules for universal energy transmission possibilities |

NSR-A Downloads

IM0012012

You need to

register

to download this file.