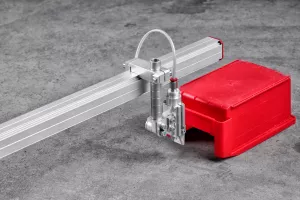

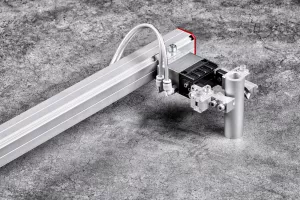

SCHUNK ORG Specifications

Ranked Nr. 348 of 235 Grippers

Grippers, attached with appropriate top fingers allows assembly of O-rings, including square rings and others both on shafts (external assembly) and in bores (internal assembly)

Choose your model:

| Number of fingers |

|

| Operation type |

|

| Extra info | O.D. and I.D. assembly with one gripper for flexibility and cost-saving / Reliable performance due to new mounting principle for high availability / Standard assembly finger for O.D. assembly for conventional ring sizes for fast commissioning |

ORG Downloads

IM0004259

You need to

register

to download this file.