SOLOMON vision AccuPick 2D Specifications

Ranked Nr. 33 of 85 Robot Software

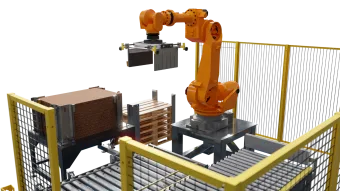

Robot vision for the factory of tomorrow

Smart Manufacturing / Smart Logistics

AccuPick 2D significantly enhances the scope of robot applications with an intelligent AI based vision system. AccuPick 2D not only gives robots ‘eyes’ that allow them to see, but also provides them with a ‘brain’ to understand with human-like cognition.

Compared to conventional rule-based vision guided robot systems,

AccuPick 2D offers the following advantages:

Recognizes complex objects and patterns using advanced machine learning

Identifies and locates objects without time-consuming optical system set-up

Works seamlessly with more than 20 robot brands and major PLCs

Friendly GUI to easily build and change workflows

Generates high return on investment (ROI)

Easily Upgraded to our award-winning AccuPick 3D

Superior detection capabilities

Unlike rule-based vision systems that often require optimal ambient lighting, which can be expensive and time consuming to attain, AccuPick 2D works perfectly under unfavorable circumstances, such as subpar lighting conditions or with poor quality images. AccuPick 2D can easily see and locate objects that have been traditionally challenging to work with, including dark, highly reflective, and transparent items. AccuPick 2D supports any GenIcam compatible with a PC-based 2D camera.

Drag-and-drop user interface to build robot applications

AccuPick 2D – Smart Manufacturing / Smart Logistics offers the possibility to give direct commands to robots. Setting them up for different vision applications and workflows does not require intimate knowledge of robot programming. All workflows can be built and changed using a drag-and drop GUI.

Support of more than 20 robot brands in AccuPick 2D

Like AccuPick 3D, AccuPick 2D supports seamless connectivity with more than twenty robot brands and allows direct communications with many major PLC brands. Users can easily upgrade to our award-winning AccuPick 3D Random Bin Picking system. AccuPick 2D and AccuPick 3D software provides a similar user interface, minimizing the amount of time required to get familiar with our 3D vision system.

| Software type |

|