SOLOMON vision Solvision Use-Cases

Ranked Nr. 15 of 85 Robot Software

Presence/Absence Detection

Push-through-package (PTP) blister production lines on average pack 5,000-40,000 tablets or capsules per hour, and are prone to occasional errors in filling. These production errors can range from unfilled and deformed blisters to inadequate or broken tablets or capsules.

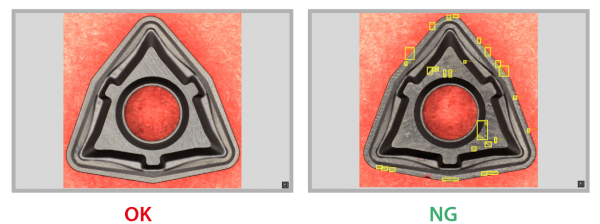

Defect Identification

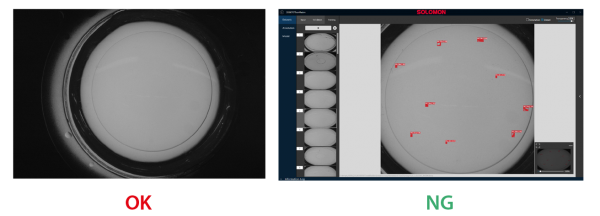

Mildew and stains sometimes remain in the bottle even after the disinfection process. However, checking for defects involves rotating and moving the bottle, and there is usually a product label in the way that makes it unfavorable for manual or traditional vision systems.

Categorization

Based on deep learning technology, Solvision can locate and mark the position of eggshell defects on sample images to train an AI inspection system. The AI model can then detect pores and cracks on the eggshell surface and classify eggs into the trained categories to meet safety standards and increase commodity value.

Solvision Production Line Defect Inspection

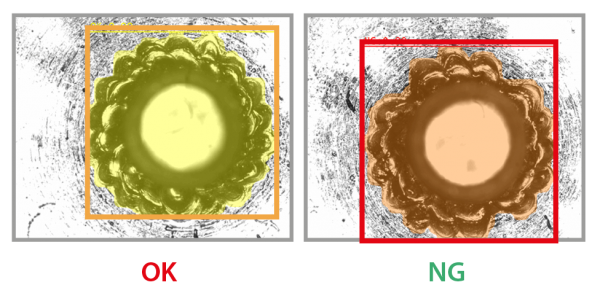

Metal scratch defects

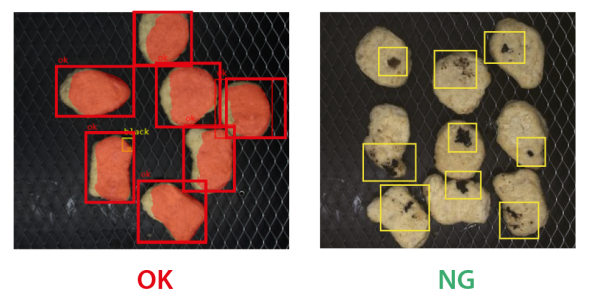

Chicken nugget defects

Contact lenses defects

Laser welding defects