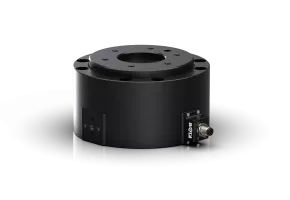

Spin Robotics SD35 Specifications

Ranked Nr. 107 of 116 End of Arm Tools

SD35 – All-in-one screwdriving solution. Inserts up to 6 screws in less than a minute, even in narrow and hard-to-reach spaces.

The SD35 is a brushless screwdriver system designed for use with collaborative robots for safe, easy-to-use, and consistent screw assembly for screws requiring up to 3.5 Nm of tightening torque. The SD35 has several build-in features.

The SD35 is made for pick & place screwdriving applications. This means that screws are picked up from an automatic screw feeder positioned within the reach of the robot and screwed in at programmed insertion points.

SAFETY SHIELD

The safety shield covers the bit and screw when on the move, thereby protecting the operator from rotating and sharp elements. If the tool unexpectedly runs into an object, a safety sensor stops the robot immediately. The built-in safety sensor is a performance level-d, making safe implementation easy.

EASY ROUTE PROGRAMMING

The supplied teach pen helps the user to set up the exact position of the screw insertion points. When the free-drive button is pressed the tool can be moved to the next position. Use the configurable button to save waypoints, start the screwdriver and more.

AUTOMATIC BIT CHANGE (OPTIONAL)

If you use different types and sizes of screws at the same workstation, we recommend the automatic bit changer that can autonomously switch between different screw bits and is to be used in combination with additional screw feeders.

COUNTER-BORE HOLES AND HARD TO REACH SPACES

Screws can be inserted in counter-bore holes with up to 15 mm depth from the surface.

| Type |

|