TAD Bowl Feeders Special configurations Alternatives & Competitors

Ranked Nr. 95 of 98 Robot Accessories

Top 10 Special configurations Alternatives

- TAD Bowl Feeders Autonomy unit with elevation

- TAD Bowl Feeders Superimposed autonomy unit

- RNA Vibration Platform FlexType P

- Brovind Step-feeder

- REECO Vibratory Bowl Feeders

- OMRON AnyFeeder Part Feeding Solution

- RNA Robotic Feeding Systems FlexType R

- Asyril Asyril feeders for components from 0.1 mm to 150 mm

- Zlin Robotics Vibratory feeders

- fancort industries ANYFEED™ SX340

- fancort industries ANYFEED™ SX240

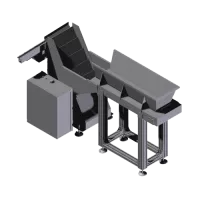

RNA Vibration Platform FlexType P

FeedersFlexType P offers you a pre-configured feeding system adapted to your parts that is based on our FlexCube vibration platform with hopper, parts recirculation and camera system.

FlexType P features an integrated vibration platform. Specific movements can be programmed in the x, y and z directions on the vibration platform. Taking into account their properties, parts are therefore handled in such a way that a high number of parts are ready to be picked up. This enables higher feeding capacities compared to uncontrolled vibration platforms. By offering freely programmable flipping amplitudes, it even allows to place elongated parts upright, or to fill pockets mounted directly onto the platform.

Based on a modular system, RNA also offers dual systems, as illustrated, with two platforms operating independently in parallel. Models with hopper, quick emptying system and parts recirculation for short changeover times are optionally available. Possibility of combining different robot and control systems or handling gantries.

Brovind Step-feeder

FeedersBrovind's Step Feeders are a versatile and complementary technology to vibratory feeders, expanding the possibilities for creating feed and selection systems. Built in a vertical execution, they are designed to lift and meter products while maintaining compact dimensions and significant capacities. The material is picked in small quantities and lifted to the outlet point through a system of counter plates. Once at the outlet, a custom-built vibratory channel feeds and orients the parts. These feeders can be built with a pneumatic or motor-driven control in standard or customized versions, with the ability to adjust the loading hopper capacity or plate thickness to suit specific requirements.

REECO Vibratory Bowl Feeders

Feeders

Specialists in automation, Reeco supply Vibratory Bowl Feeders which can be custom tooled to your requirements. The bowl feeders are self-contained products with a special bowl to orientate the parts, driven by a drive unit which pushes parts upwards on an inclined circular track. Ideal for those who require turnkey automation solutions, we offer a solution that fits the product, commonly M4-M12 bolts, bottle tops, screws and cap screws with a feed rate of up to 100pcs/min.

With sizes ranging from 300-650mm, the bowl can hold anywhere from 500-10,000 parts depending on the application, making them a versatile solution. The bowl feeders are made from stainless steel and have a rubber coating to dampen sound, avoiding the need for soundproofing and also reducing wear overtime. Featuring dual control from the bowl to the feeder, high throughput of parts is guaranteed.

Reeco vibratory bowl feeders can be tooled for the selection of specific components to ensure the feeder is tailored to your requirements. As bespoke automation specialists we can help you select the best product for your application.

OMRON AnyFeeder Part Feeding Solution

Feeders

Complete, flexible feeding system optimized to work together with vision, motion and robots.

Designed to work with a variety of robots and in combination with Omron Vision software and controller, the AnyFeeder Solution provides an efficient and fast-feeding solution. Its flexibility in feeding small parts of various sizes, shapes and materials allows for fast line changeover and significantly reduced tooling costs to give you a crucial competitive advantage.

RNA Robotic Feeding Systems FlexType R

Feeders

Get everything from one single source: FlexType R

With our innovative FlexType R feeding systems, we combine the advantages of feeding technology and robotics.

We plan, design, assemble, program, optimize, install and ...

Technology that can do more:

- Do your parts tend to tangle up or interlock? (part accumulation not possible)

- Do you want to process families of parts?

- Do your parts present complex geometries?

Then FlexType R is the right technical solution for your requirements.

Adaptable and cost-efficient:

- Do your products have a short market life and are they subject to modifications?

- Do you manufacture small lot sizes?

Then FlexType R is the right economic solution for your requirements.

In addition: FlexType R has a high presentation rate (parts in a pick-up position) to ensure maximum utilization of the robot cycle time, thus guaranteeing high cost-efficiency.

Asyril Asyril feeders for components from 0.1 mm to 150 mm

FeedersAsyril has developed vibratory parts feeders to offer an efficient solution for the unbulking of all types of components delivered in bulk. The Asycube is compatible with all robots and PLCs thanks to its TCP/IP and Modbus TCP compatible communication. Various plugins are available for easy system integration. Using Asyril’s EYE+ smart control system, will allow you to optimize the performance of your Asycube.

Our 3-axis vibration technology offers unprecedented optimization of the feeding and sorting process

This system moves parts quickly in all directions, eliminates corner and edge build-up, eliminates part recirculation, and handles delicate parts smoothly with precise frequency and amplitude control. Asyril’s patented 3-axis technology allows better cycle times and optimal efficiency of your machine even on structured, slotted or perforated platforms.

Easy to change

Quick and easy changeover from one series to another thanks to simple settings of different vibration recipes and tool-free platform change.

Zlin Robotics Vibratory feeders

Feeders

With the increasing automation grade of assembly lines, robotic cells and single purpose machines, it is necessary to automate the feeding of components.

Therefore, since 2011, we offer our customers a complete solution and delivery of automatic vibratory feeding technologies.

We offer:

- complete delivery of vibratory feeding technologies (bowl feeders, linear feeders)

- sound insulation for feeding technologies

- vibratory and conveyor belt-based bunkers and hoppers

- pick up places for vibratory bowl feeders

Current delivery terms for our bowl feeders are starting from 7 weeks after receipt of a purchase order and parts.

In case the application requires high flexibility, we offer also high-tech and flexible feeding technologies based on a camera searching for components and following robotic pick and place. Parts can be fed either by conveyor belt or by flexible vibratory plate. With such technology, you can feed components in the size range of about 0.1 mm up to 150mm.

References:

Since 2011, we have maintained in operation dozens of vibratory feeders, hoppers and other feeding technologies. They have all processed and fed hundreds of millions of part of many different shapes and geometries.

fancort industries ANYFEED™ SX340

FeedersThe anyfeed SX340 is a flexible bulk parts feeder with an integrated bulk storage bin that can hold components of arbitrary shapes and materials. When combined with flexfactory’s vision solution or and your robot of choice, the anyfeed SX340 becomes a highly versatile robot feeding system that offers solutions for a wide range of application requirements. Controlled by the vision system, the anyfeed SX340 uses its servo-electric drives to move the components into positions that can be easily picked by the robot.

The anyfeed SXM line of feeders is based on a feeding method patented by flexfactory that does not require high maintenance conveyor belts or expensive recirculating systems. The ‘first-in-first-out’ principle of the anyfeed SX340 is an efficient and reliable handling method that ensures parts spend as little time as possible in the feeding system, waiting to be picked.

Features:

• Robust, conveyor-belt-free design with a very small footprint

• Gentle part handling thanks to first-in-first-out principle and no recirculation

• Quick-change feed surfaces in various colors, materials and surface finishes

• Materials that come into contact with parts: POM, WN1.4301, anodized aluminum

• Maintenance free, brushless servo drives

• Fully integrated controls

• Rapid parts supply thanks to configurable feeder actions and structured feeder surfaces

• Multiple feeders can be used with one robot

• Power supply: 24V DC supply voltage, no compressed air

• Communications interface: RS232, or Ethernet TCP/IP in combination with Cognex In-Sight

Special features:

• Version available for applications with an external bulk

• The integrated bulk is emptied via the feed surface. Bulk exit is equipped with a flap, which prevents accidental falling down of parts into the gripping area

• FOV support plate is supplied as standard