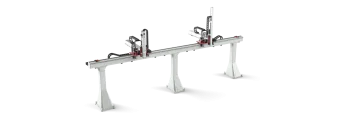

YASKAWA Gantry robot TSG Specifications

Ranked Nr. 41 of 36 Cartesian (Gantry) Robots

The TSG gantry is designed to provide reliable, accurate and economical welding solutions for the production of very large components such as excavators, containers and earth moving equipment.

The TSG is servo powered and fully synchronised with the robot controller. The gantry's Y beam structure is built using two and four metre modules to the required length with a suitable number of supporting pillars.

In twin systems where multiple robots run on the Y beam, the robots can work together or independent of each other.

- Outstanding speed

- Modular design

- Single, or twin robot systems

| Number of Axis |

Gantry robot TSG Downloads

TSG 1079 EN 01

You need to

register

to download this file.