Valentin Hendrik

HDVisionSystems

Oct 19, 2022

Period

- 2022

Robot

Universal Robot 5 CB-Series

Title

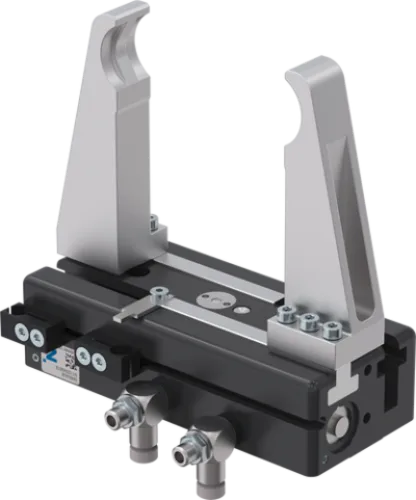

The task was to place products on trays and remove them from the trays. Increased precision had to be maintained. The gripper was used because a certain position had to be maintained both when approaching the gripping point and when letting go. In addition, very long gripper jaws had to be used for the product. However, these gripper jaws had to be custom-made.

Pro

Once the gripper was in operation, Zimmer's in-house program made it easy to teach the position. The gripping force and the position when spreading the jaws was also very easy to program. Error messages could be read out directly in the program, so that the manual did not have to be read through every time with cryptic error codes. Product support was available.

Con

The gripper was simply much too heavy for a cobot application. The gripper alone weighed around 4 or 5 kg, so that the robot constantly generated errors. In addition, the gripper was so large that the robot constantly drove into itself or parts of the gripper. Only with great effort and many intermediate positions could this be avoided. The electrical installation was also, due to the fact that a CB-Series robot was used, not as easy as with an E-Series UR robot. An additional power supply unit had to be used, as well as more complex cabling. For this installation, a technician was provided by phone for one hour.