Zimmer SERIES GPH8000 Alternatives & Competitors

Ranked Nr. 88 of 235 Grippers

Top 10 SERIES GPH8000 Alternatives

- AGS Gripper Fingers

- SCHUNK PLG

- Gimatic KIT-UR-J

- SCHUNK PFH

- RÖHM Parallel Gripper

- AGS Gripper System

- RÖHM RPP-A 125

- RÖHM RPP-A 160

- RÖHM RPP-A 100

- RÖHM RPP-A 80

- RÖHM RPP-A 64

AGS Gripper Fingers

Angular | Parallel | RadialAGS Automation's Gripper Fingers, also known as GFI grippers, are designed to handle components that are too heavy for vacuum suction cups. When the demolding forces or handling weight are too great, these gripper fingers come in handy. They come in various sizes, with different finger shapes, to suit different components. The modular system of AGS Automation's gripper fingers offers a wide range of accessories that can be added to customize the gripper fingers to the specific application.

The functional range of AGS Automation's gripper fingers is diverse. The gripper fingers can be single-acting or double-acting, with or without self-locking. Single-acting gripper fingers are suitable for simple pick and place operations, while double-acting gripper fingers are useful for more complex applications that require additional control. The self-locking feature provides additional safety by locking the gripper fingers in place, preventing accidental release of the component.

AGS Automation's gripper fingers can be used in various industries, including manufacturing, logistics, and warehousing. They are particularly useful in applications that require picking and packing, material handling, and component assembly. AGS Automation's gripper fingers are compatible with a range of robotic arms and automation systems, making them a versatile solution for various automation applications.

In summary, AGS Automation's Gripper Fingers are a modular system of gripper fingers that can be customized with various accessories to suit specific applications. They are a good alternative to vacuum suction cups when handling heavy components, and they are compatible with a range of robotic arms and automation systems. They are best suited for industries that require picking and packing, material handling, and component assembly.

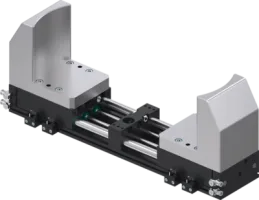

SCHUNK PLG

ParallelPneumatic 2-finger parallel gripper with large jaw stroke, high gripping force and profiled rail guide for the use of long gripper fingers.

SCHUNK PFH

Parallel2-finger parallel gripper with long jaw stroke for large parts and/or a broad range of parts.

AGS Gripper System

ParallelAGS Automation's gripper system, also known as PAG impact grippers, are designed for precision picking up of inserts, bushings, rings or screws. These gripper systems come in different sizes, with varying numbers of gripper fingers and stroke sizes, making them suitable for various applications.

One of the notable features of PAG impact grippers is the modular system that allows for optimal adaptation options in both the gripping and attachment directions. This means that these gripper systems can be customized to meet the specific requirements of each application.

The gripper fingers of PAG impact grippers move parallel to each other and are guided by a dovetail guide, ensuring precise and stable gripping of the workpiece. This parallel movement also enables the gripper system to pick up and hold small workpieces securely.

PAG impact grippers are available in both single-acting and double-acting types. The double-acting PAG grippers can be used for both internal and external gripping, while the single-acting PAG grippers are suitable for external gripping.

RÖHM RPP-A 125

Parallel

Technical Features:

- Centrically clamping in compact design made of high-strength, hard-coated aluminum alloy

- All functional parts made of hardened steel for maximum service life

- Wedge hook principle with pneumatic actuation (hydraulic actuation available on request)

- Position monitoring with inductive or magnetic position sensors

- Optionally available with FKM seals for higher temperatures up to 150°C (on request)

- Integrable purge air connection to prevent contamination

Advantages:

- High gripping force with low dead weight and compact design

- Maximum flexibility thanks to versatile connection and fastening options

- Long service life and high reliability thanks to specially ground base jaws in proven T-slot guide

RÖHM RPP-A 160

Parallel

Technical Features:

- Centrically clamping in compact design made of high-strength, hard-coated aluminum alloy

- All functional parts made of hardened steel for maximum service life

- Wedge hook principle with pneumatic actuation (hydraulic actuation available on request)

- Position monitoring with inductive or magnetic position sensors

- Optionally available with FKM seals for higher temperatures up to 150°C (on request)

- Integrable purge air connection to prevent contamination

Advantages:

- High gripping force with low dead weight and compact design

- Maximum flexibility thanks to versatile connection and fastening options

- Long service life and high reliability thanks to specially ground base jaws in proven T-slot guide

RÖHM RPP-A 100

Parallel

Technical Features:

- Centrically clamping in compact design made of high-strength, hard-coated aluminum alloy

- All functional parts made of hardened steel for maximum service life

- Wedge hook principle with pneumatic actuation (hydraulic actuation available on request)

- Position monitoring with inductive or magnetic position sensors

- Optionally available with FKM seals for higher temperatures up to 150°C (on request)

- Integrable purge air connection to prevent contamination

Advantages:

- High gripping force with low dead weight and compact design

- Maximum flexibility thanks to versatile connection and fastening options

- Long service life and high reliability thanks to specially ground base jaws in proven T-slot guide

RÖHM RPP-A 80

Parallel

Technical Features:

- Centrically clamping in compact design made of high-strength, hard-coated aluminum alloy

- All functional parts made of hardened steel for maximum service life

- Wedge hook principle with pneumatic actuation (hydraulic actuation available on request)

- Position monitoring with inductive or magnetic position sensors

- Optionally available with FKM seals for higher temperatures up to 150°C (on request)

- Integrable purge air connection to prevent contamination

Advantages:

- High gripping force with low dead weight and compact design

- Maximum flexibility thanks to versatile connection and fastening options

- Long service life and high reliability thanks to specially ground base jaws in proven T-slot guide