As consumer expectations for faster deliveries and seamless order fulfillment grow, the logistics and e-commerce industries are under increasing pressure to optimize efficiency. To help businesses stay ahead, ABB is introducing new automation solutions designed to enhance speed, accuracy, and adaptability in warehouse operations.

Let’s take a closer look at how they work, their key benefits, and how they can transform logistics operations.

The Need for Smarter Logistics Solutions:

E-Commerce Boom Increases Demand for Efficiency:

The rise of e-commerce has led to an exponential increase in parcel volumes, pushing warehouses and fulfillment centers to find smarter, more efficient solutions. Customers now expect faster deliveries and error-free orders, making traditional manual sorting and picking methods increasingly unsustainable.

Challenges with Manual Sorting and Picking:

Manual logistics processes are not only slow and labor-intensive but also prone to human errors. This can lead to:

- Misplaced items

- Incorrect shipments

- Costly delays

As order volumes grow, relying on human workers alone can cause bottlenecks and inefficiencies in fulfillment centers.

AI-Powered Robotics as the Solution:

To solve these challenges, businesses are turning to AI-powered robotics that can handle repetitive, high-speed operations with precision. ABB’s latest robotic modules integrate:

- Artificial intelligence for accurate picking

- Advanced vision systems to identify items in unstructured environments

- High-speed automation to boost productivity

By adopting these smart solutions, logistics companies can improve efficiency, reduce labor dependency, and enhance order accuracy—ensuring a seamless supply chain for the future.

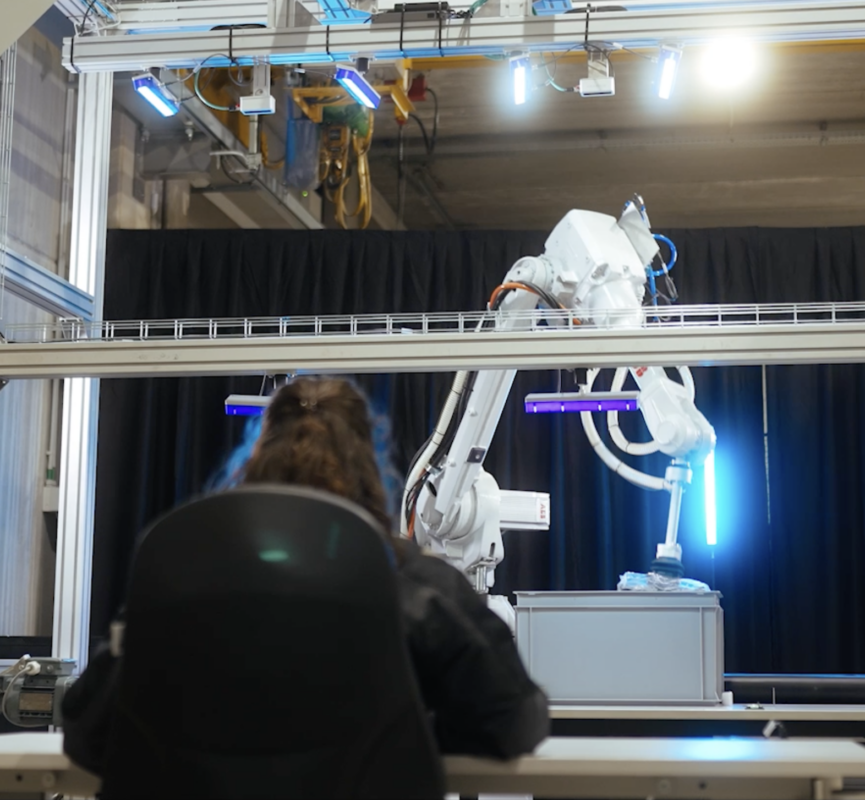

Meet ABB’s Newest Item Picking Robots:

ABB’s Robotic Fashion Inductor and Robotic Parcel Inductor are designed to supercharge logistics operations across multiple industries. Whether in fashion fulfillment centers, courier sorting facilities, or e-commerce warehouses, these robots help businesses process parcels and goods with unmatched speed and accuracy.

Here’s how they stand out:

AI-Driven Precision: Over 99.5% Picking Accuracy

One of the biggest challenges in warehouse automation is dealing with unorganized and unpredictable environments—where parcels come in different shapes, sizes, and materials. ABB’s AI-powered vision system ensures that its robots can identify, handle, and sort packages with over 99.5% accuracy, even in cluttered conditions.

This advanced vision technology allows the robots to adapt to new items on the fly, meaning businesses don’t have to manually program each new product type. It also reduces the likelihood of errors, ensuring that the right items are picked and sent to their correct destinations.

Unmatched Speed: Up to 1,500 Picks Per Hour

Speed is everything in modern logistics. With the ability to pick and place up to 1,500 items per hour, ABB’s robots significantly boost throughput, helping businesses meet demanding order fulfillment targets.

By automating these tasks, warehouses can process more parcels in less time, leading to faster deliveries and happier customers.

Effortless Integration: Plug-and-Play Setup

One major barrier to adopting robotics in logistics is the complexity of integration. Many automation systems require extensive setup, software adjustments, and staff training. ABB’s new picking robots, however, are designed for seamless deployment.

Equipped with a user-friendly application controller platform, these robots can be easily connected to existing warehouse management systems, reducing commissioning time and eliminating the need for complex programming. This plug-and-play approach ensures that businesses can quickly scale up their automation efforts without significant downtime.

How These Robots Transform Logistics Operations:

ABB’s new Item Picking robots are built to solve real-world logistics challenges. Here’s how they make a difference in key industries:

E-Commerce and Order Fulfillment:

Faster Order Processing: Picking, sorting, and packing orders at lightning speed to meet same-day or next-day delivery expectations.

Error-Free Shipments: AI-driven vision ensures accurate order fulfillment, reducing costly returns and dissatisfied customers.

Retail and Fashion Distribution:

Handling Delicate Items: The Robotic Fashion Inductor is designed to handle soft, lightweight, and delicate materials without damage.

Adapting to Trends: As fashion trends change rapidly, AI-powered robots can learn and adapt to new products without requiring manual programming.

Courier and Parcel Sorting:

Managing High Parcel Volumes: The Robotic Parcel Inductor can sort thousands of parcels per shift with precision, optimizing last-mile delivery.

Reducing Labor Dependency: With automation, logistics companies can reduce reliance on manual labor, cutting operational costs while increasing efficiency.

A Smarter Future for Logistics with ABB:

With the expansion of ABB’s Item Picking family, businesses now have access to next-generation robotic solutions that are fast, accurate, and easy to integrate. By combining AI vision, high-speed automation, and user-friendly controls, these robots are setting new benchmarks in logistics performance.

Whether you’re a retailer looking to streamline order fulfillment or a courier company aiming to optimize parcel sorting, ABB’s new robots offer the tools needed to stay ahead in the competitive logistics landscape.

Key Takeaways:

- AI-powered robots ensure over 99.5% picking accuracy

- Speeds of up to 1,500 picks per hour boost efficiency

- Plug-and-play integration minimizes setup time

- Ideal for e-commerce, retail, courier services, and logistics hubs

- Reduces labor dependency and cuts operational costs

By adopting ABB’s Robotic Fashion Inductor and Robotic Parcel Inductor, companies can future-proof their logistics operations, ensuring faster deliveries, fewer errors, and greater scalability.

Learn more about ABB’s automation—check out their full article.