If you’re in manufacturing, staying ahead is all about smart automation. Autonomous Mobile Robots (AMRs) are not just machines; they’re your dynamic partners on the shop floor. They navigate through your workspace, avoiding obstacles and ensuring safety, all while boosting your productivity and cutting down costs. No matter your industry, AMRs easily adjust to your operations, helping you scale effortlessly.

Let’s explore the top benefits of integrating AMRs into your business.

But before we begin…

What are AMRs?

AMRs are robots that can move and do things on their own without people controlling them directly. They have sensors and cameras to see and understand the world around them. These robots are handy in places like warehouses, hospitals, and factories where things are always changing.

Unlike old-style robots that need fixed paths, AMRs are smart. They use technology like cameras and special sensors to figure out where they are and what’s around them. This helps them do tasks like moving things or keeping track of inventory without needing people to tell them what to do every step of the way. They’re like little helpers that can think for themselves!

How do AMRs Work?

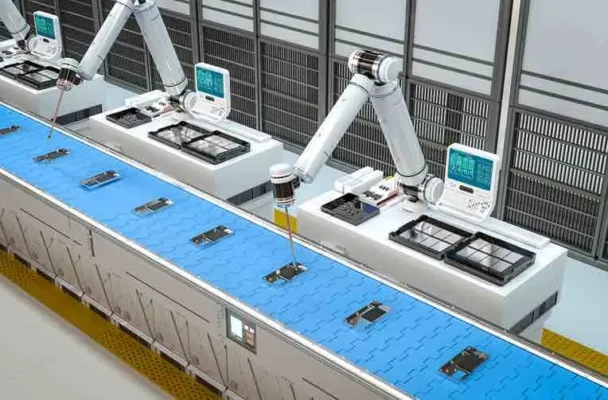

Autonomous Mobile Robots (AMRs) are like your most efficient workers, but with an added layer of intelligence for navigating your production space. Here’s the breakdown: These robots are kitted out with sensors and smart tech that let them see and understand their surroundings. When you assign an AMR a task, it immediately gets to work, mapping out its environment to find the best path to its destination.

But here’s the cool part: if something blocks their way, AMRs don’t just stop and give up. They quickly figure out an alternative route and keep moving. This means they’re always on the go, doing their jobs without needing someone to watch over them.

And they’re not loners; AMRs talk to each other and to a central system through wireless networks. This keeps everything running smoothly, making sure robots aren’t getting in each other’s way.

Common Applications of AMRs:

Picking & Packing:

AMRs speed up how orders are put together. They move fast, picking up the right items without mistakes. This means your customers get what they ordered sooner, and you deal with fewer wrong orders.

Material Transportation:

Whether it’s delivering materials to where your products are made or taking finished goods to storage, AMRs handle the heavy lifting. They can carry big loads, making sure everything gets to the right place quickly. This keeps your operations moving fast and saves your team from doing the heavy lifting.

Inventory Management:

AMRs help you stay on top of what you have in stock. They scan items and update your inventory in real time. Knowing exactly what’s in stock means you won’t order too much or run out of something you need.

Inspection & Monitoring:

In places where quality can’t be compromised, AMRs keep an eye on things. They check on products and conditions around the clock, letting you know if something’s not right. Catching issues early keeps your operations smooth and ensures what you produce meets your high standards.

Now let’s check out the top 9 advantages about these mobile robots:

9 Advantages of AMRs:

1. Quick Installation & Adaptability:

AMRs are good because they can be set up fast. Unlike other machines that need big changes to the place, AMRs fit into the warehouse without much trouble. This helps save time when setting up or making changes.

2. Safety:

Safety is important in a warehouse, and AMRs make sure to be safe. They move at a steady speed, avoid things in their way, and follow safety rules. This makes sure accidents are less likely, keeping both the robots and people safe.

3. Consistent Performance:

AMRs work very precisely. They do tasks the same way every time and don’t make mistakes like tired humans might. This helps get orders right and reduces errors.

4. Collaborative Work (Cobots):

AMRs work well with people. They look friendly and do simple jobs, letting people focus on harder tasks. It’s like they’re good buddies helping each other out.

5. Removal of Repetitive Tasks:

AMRs do jobs that repeat a lot. This helps human workers because they get more time to do interesting work instead of the same thing over and over. It makes work more enjoyable.

6. Cost Optimization & Staffing Efficiency:

AMRs save money. They bring things directly to human workers, so workers don’t have to walk around so much. This helps keep costs steady, unlike paying more when people work more.

7. Environmental Friendliness:

AMRs are kind to the environment. They run on batteries and don’t make much pollution. This makes them good for places that need to stay clean, and they don’t create pollution when they move.

8. Easy Scalability:

AMRs are flexible and can change as needed. If you need more of them, you can add them easily. If you don’t need as many, you can take some away. This flexibility helps warehouses stay adaptable and ensures that things are available, cost-effective, and of good quality.

9. Continuous Operation:

AMRs can work all the time. They don’t need breaks, vacations, or more money for working more. This is great for keeping work going without stopping.

Conclusion:

Bringing Autonomous Mobile Robots (AMRs) into your operation is a smart move towards a more efficient workplace. They effortlessly take on moving goods, keeping track of what you have, and making sure everything runs smoothly. This means you can focus on growing your business and thinking about new ideas.

Do you want to compare different AMRs?

Join the Qviro community to explore how AMRs can revolutionize your production line and discuss insights with industry experts. Join the Qviro Community

The very root of your writing whilst sounding agreeable originally, did not work very well with me after some time. Someplace within the sentences you managed to make me a believer unfortunately only for a very short while. I however have got a problem with your leaps in assumptions and you would do nicely to help fill in those gaps. In the event that you can accomplish that, I will certainly be fascinated.