In factories and making things, there’s a new way called Industry 5.0. It’s the latest method, focusing on making production more personal, eco-friendly, and effective.

In this article, we’ll explore what sets Industry 5.0 apart from Industry 4.0. We’ll discuss its unique features, why it’s beneficial, how it operates, and where it fits in the history of making things.

What is Industry 5.0?

Industry 5.0 is the latest way we make stuff in factories, and it’s a big change from Industry 4.0.

Before, machines did a lot on their own, but now it’s all about humans and machines teaming up. In Industry 5.0, we want people and machines to work together in a balanced way. This means humans use their smarts for tricky tasks, and machines handle repetitive or dangerous jobs. It’s about making work better for everyone, boosting productivity, and creating a friendlier workplace.

This new approach is a step up from the old “machines do everything” idea, bringing a more teamwork vibe to how things get made.

What’s the difference between Industry 5.0 & Industry 4.0?

In Industry 4.0, machines did things automatically, working on their own. But in Industry 5.0, there’s a shift – it’s about people and machines working together. This change is significant because it values both humans and machines, unlike the previous focus on machines doing everything alone.

In Industry 5.0, teamwork is the main idea, aiming for a workplace that is more balanced and friendly. It’s a departure from the previous way of doing things, emphasizing collaboration for better outcomes.

Evolution of Industry 5.0:

The newest way we make things is called Industry 5.0. In the past, we had Industry 4.0, where machines did things automatically. But now, with Industry 5.0, we’re focusing on people and machines working together. This is a big deal because it sees people as important, not just tools. The goal is to use both human creativity and advanced technology to get better results.

Each revolution brought different changes. But Industry 5.0 is special because it’s all about humans and machines working together in a collaborative way.

5 Key Characteristics of Industry 5.0:

Industry 5.0 is a big change in how things are made. Here are some important things about it:

1. People and Machines Work Together:

In Industry 5.0, people and smart machines work closely. They help each other do their jobs better. This is different from before when machines did most of the work alone. Now, people and machines are partners.

2. Machines Make Work Personal:

The goal of Industry 5.0 is to make production more personal. Machines don’t just make the same things for everyone. They can make things that fit what each person wants. This is good because it reduces waste, and we only make what people really need.

3. Machines Talk to Each Other:

In Industry 5.0, machines talk to each other through the Internet of Things (IoT). This means they can share information and work together better. It makes work more efficient and helps us use resources in a smart way.

4. Humans Become Better with Machines:

Industry 5.0 is not about replacing people with machines. It’s about making people better with the help of machines. Machines are like tools that make our work easier. They can do repetitive tasks, leaving more time for people to think and create.

5. Everything is Connected:

One cool thing about Industry 5.0 is that machines are connected. They can communicate in real-time. This helps things run smoothly. It’s like everyone in a team talking to each other to get the job done right.

5 Benefits from Industry 5.0:

1. Better Jobs:

Industry 5.0 wants to make jobs better by bringing in new ideas and creativity.

2. Special Products for You:

When people and machines work together, they can make products just for you. This makes your experience more personal.

3. More Freedom for Workers:

Technology helps workers have more freedom in making things. This makes work easier and more creative.

4. Caring about the Earth:

Industry 5.0 really cares about the environment. It deals with environmental problems by using a circular economy approach.

5. Better Work Atmosphere:

When people and machines team up, it makes the workplace more interesting and productive. This makes work a better place to be.

Strategies of Industry 5.0:

1. People First Approach:

Industry 5.0 changes how we see workers. Instead of just resources, they are seen as valuable assets. This strategy aims to make work better by focusing on creativity and new ideas.

2. Building Strength in Challenges:

Industry 5.0 wants organizations to be strong and flexible. This helps them handle problems and stay stable during tough times. Being resilient is crucial for long-term success.

3. Benefitting Everyone:

Industry 5.0 isn’t just about being good for the environment. It also wants organizations to do good in other areas, like being responsible in society and making a positive impact on the economy. This approach is called ‘Net Positive.’

Applications & Examples in Industry 5.0:

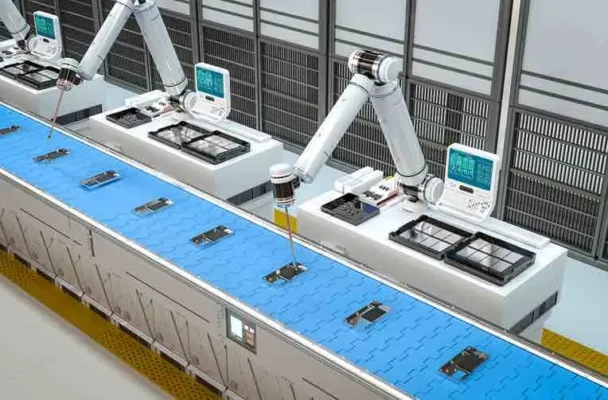

1. Working Together – ‘Cobots’:

Industry 5.0 brings in the idea of ‘Cobots,’ which are robots that work with people. They are seen in different industries, such as medicine, fashion, and car assembly.

2. Helping in Surgery:

In medicine, these collaborative robots assist surgeons in delicate operations. They make surgeries more precise and lower the chance of mistakes.

3. Fashion that Fits You:

In the fashion world, Industry 5.0 lets us make clothes just for you. This changes how we think about style, letting us customize clothes to match our preferences.

4. Smooth Car Building:

Car factories show how well humans and cobots can work together in Industry 5.0. They make the process smoother and more efficient, improving how cars are put together.

Conclusion:

Industry 5.0 is how we make things now, not like the old Industry 4.0 where machines did everything alone. In Industry 5.0, people and machines work together for better jobs and personalized products. This is a big change, focusing on teamwork between humans and machines to make production better and friendlier to the environment.

Do you want to compare different Industrial Automation?

Join the Qviro community to connect with industry experts and explore how Industry 5.0 can revolutionize your manufacturing processes. Join the Qviro Community

Are you looking for a System Integrator?

Interesting!

Robot never sleeps. It makes money for you 24/7.

Robots are the best way for everyone who is looking for financial independence.