*Promotional*

In the fast-moving world of industry, it’s super important to choose the right cobots to work with people. This decision can really impact how well things work in a business.

“Collaborative robots offer enhanced safety, ease of use, simple operation, and greater flexibility, making them ideal for small-batch, multi-variety production scenarios. However, their application in the industrial field has limitations, with more expansive opportunities in non-industrial sectors.”

– Li Gang, President of Aubo Robotics, 2023

What is an Industrial Cobot?

An industrial collaborative robot, or cobot, is a special kind of robot that works alongside people in factories. Unlike regular robots, cobots are made to be safe and easy to use.

For example, in a factory, an industrial robot might help move heavy things or assemble products. The cobot can do this without hurting anyone and can be easily taught what to do. It’s like having a smart assistant in the factory, making work faster and safer.

6 Applications for Industrial Cobots:

1. Lifting & Moving:

Cobots make it easy to lift and move heavy things. They help you handle big objects without much effort.

2. Assembly:

Cobots are crucial in assembling things during manufacturing, making sure everything is put together accurately.

3. Quality Checks:

Cobots can learn to make sure products are made right, keeping up high-quality standards.

4. Warehouse Tasks:

In warehouses, cobots are helpful for lifting and moving boxes, which makes handling goods easier and enhances logistics.

5. Collaborative Work:

Cobots work alongside people in factories, assisting with tasks and making work more efficient.

6. Task Automation:

They can do repetitive jobs automatically, so human workers can concentrate on more complicated tasks.

Cobots make different industries more flexible and efficient, acting like helpful teammates in manufacturing.

5 Promising Industrial Cobots of 2023:

1. AUBO i20:

The AUBO i20 is a strong and precise robot suitable for heavy lifting and accurate movements. It is ideal for businesses needing reliable high performance. The robot understands languages like C, C++, C#, Lua, and Python and can communicate with different systems such as Linux, Windows, or ROS.

AUBO robots work well with various tools, performing tasks like welding, palletizing, machining, and cutting. Before starting work, the i20 undergoes tests for shaking, high heat, wear and tear, and precision to ensure strength and reliability over time.

2. TM5-700 & TM5-900:

Techman Robot’s TM5-700 and TM5-900 are robots that can see things. They’re good for small and medium-sized businesses. These robots have special eyes (cameras) to help them work better. They can check things, make sure they’re good quality, and move them around. This makes work faster and cheaper.

Programming these robots is easy. You don’t need to know a lot about computers. You can use a simple program that lets you click and move things. Even if you never programmed before, you can learn in just a few minutes.

Safety is important. These robots follow safety rules to stop if something is wrong. They can even work close to people without hurting them. This keeps everyone safe.

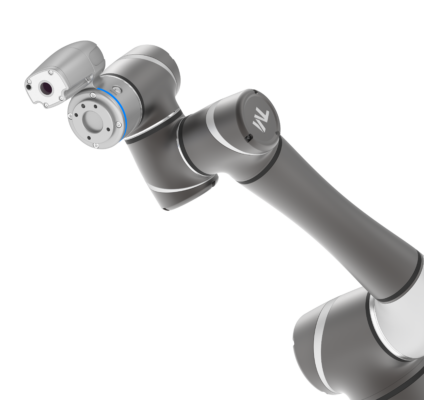

3. UFACTORY XARM:

UFACTORY XARM is well-known in industrial cobots, providing flexibility and user-friendly features. It easily works with various tools like grippers, vacuum grippers, and force torque sensors, making it suitable for different tasks. Its easy design simplifies programming with a graphical interface and drag-and-drop features, letting users create code quickly, even without coding experience.

UFACTORY also offers real-time support through chat, ensuring help is available when needed, giving users guidance on their laptop or mobile phone.

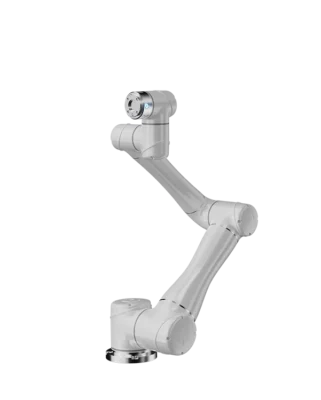

4. Elite Robots’ EC66:

Elite Robots’ EC66 is a collaborative robot crafted for reliability and cost-effectiveness, equipped with a 6 kg payload and a 914 mm radius. Its lightweight design and advanced features, such as collision detection and remote control, make it suitable for various applications.

The EC66 is used in various industries such as plastic processing, biotech, metalworking, and logistics. Elite Robots promotes teamwork by combining tools and systems from other makers. This creates tailored and efficient automation solutions that suit each business’s special needs.

5. JAKA Zu S Series:

JAKA Zu S series cobots are small and advanced collaborative robots, ensuring safety and precise interaction with integrated force sensors.

These cobots adapt to their environment, providing real-time force values and control settings through the user-friendly JAKA app, thanks to a force control algorithm with three modes.

The Zu S Series cobots do different jobs like polishing, sanding, PCB assembly, and palletizing. They’re reliable with a remarkable MTBF of 50,000 hours and need little maintenance. You can install them at any angle, and there’s no need for safety fences. They’re used in many industries to automate tasks, making work safer and more efficient.

Conclusion:

In the fast-changing world of industry, this year, 2023, introduces a group of promising industrial cobots. These robots are set to improve how things work, making tasks more efficient and safer in different areas.

*Promotional*

Are You Looking For A Systems Integrator?

It’s actually nice and useful piece of info. I’m happy that you shared this helpful information with us. Thanks for sharing.