When thinking about investing in Automated Guided Vehicles (AGVs) into your manufacturing line, knowing how much they’ll cost is crucial. AGVs are transforming manufacturing and logistics, making operations smoother and more efficient. But, with so many options and tech out there, prices can vary a lot.

This guide will help you get a clear picture of the average price of AGVs in 2025.

We’ll dive into what impacts their costs and give you the lowdown on budgeting for them, so you can make the best decision for your project.

Understanding AGVs:

What are AGVs?

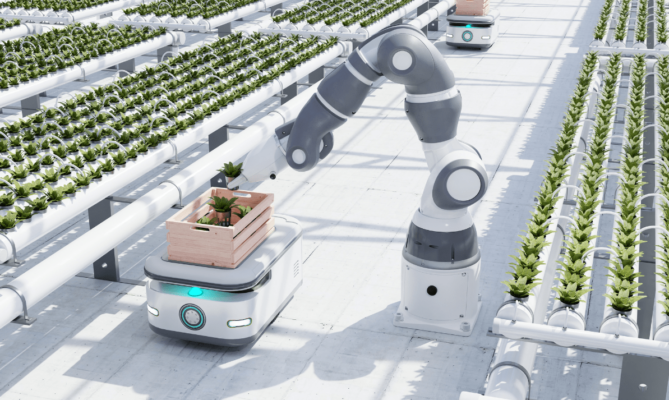

Automated Guided Vehicles (AGVs) are the silent workhorses of the manufacturing and logistics world. Smart, self-driving carts that move materials around without needing a person to guide them. They follow pre-set paths to transport materials from point A to point B, making sure that everything from raw materials to finished products gets where it needs to go, safely and efficiently. They do all this by themselves, thanks to clever tech like lasers, magnets, or even cameras to see their way around.

The Role of AGVs in Industrial Automation

AGVs play a big part in automating routine tasks. They take over the heavy lifting and repetitive moving jobs, freeing up humans to focus on more complex tasks. This not only speeds things up but also cuts down on mistakes and workplace accidents. With AGVs, businesses can keep their operations running smoothly around the clock without wearing out their human workforce.

This video showcases how Nissan’s automated guided vehicles (AGVs) use repurposed LEAF batteries and motion sensors to streamline car manufacturing and improve efficiency.

Types of AGVs and Their Uses

AGVs come in various shapes and sizes, each designed for specific tasks. Here’s a quick look at the main types:

Tow Vehicles:

These AGVs are like tugboats for your warehouse. They pull carts behind them, making it easy to move multiple loads at once. Perfect for tasks that involve moving big batches of goods from one spot to another.

Unit Load Carriers:

Imagine a flatbed truck, but mini and automated. That’s your unit load carrier AGV. It carries single, large items or a few smaller ones stacked up. They’re great for moving goods directly on their platform, especially if those goods are on pallets.

Pallet Trucks:

Pallet trucks are the AGVs you need for picking up and moving pallets. They slide right under a pallet, lift it up, and then whisk it away to its next stop. Ideal for loading docks and warehouses.

Forklifts:

AGV forklifts do the heavy lifting—literally. They can move and stack heavy loads high up, just like a human-operated forklift, but without the need for a driver. They’re a game-changer for storing and retrieving goods on high shelves.

Each type of AGV has its place, making it easier to find one that fits your specific needs. Whether you’re moving big loads, small goods, or need something lifted, there’s an AGV out there for you.

The Real Cost of an AGV:

Thinking about adding AGVs to your line-up? Let’s talk numbers. Understanding the costs involved with AGVs can help you plan your budget and get the most bang for your buck. Here’s what you need to know.

Initial Purchase Price:

In 2025, the price tag for AGVs can swing from $40,000 to a hefty $200,000. This range isn’t just for show. It depends on what you’re looking for. Need a forklift AGV? You might be shelling out between $75,000 and $200,000. Looking at unit load vehicles? Those start around $40,000. And if a towing or tugger vehicle fits the bill, expect to invest anywhere from $50,000 to $85,000. The type, size, and how smart it needs to be (its navigation tech) play big roles in the price.

Operational Costs:

Once your AGV is rolling, it’ll need some upkeep. Think of it like a car; regular maintenance, energy to keep it moving (electricity isn’t free), and updates to its brain (software) to keep it sharp. These costs can vary, but knowing they exist helps you avoid surprises down the road.

Here’s a breakdown:

- Maintenance: Regular check-ups to prevent breakdowns can cost several thousand dollars annually, depending on usage intensity.

- Energy: AGVs run on batteries, and the cost to keep them charged varies by energy prices but expect to spend a few hundred dollars per AGV per year.

- Software Updates: Keeping the AGV’s software current is crucial for optimal operation, which might require a subscription or one-off payments, potentially costing up to $1,000 or more annually.

Installation and Integration Costs:

Getting your AGV from the box to the floor involves some setup. Integrating it with your current systems, making sure it knows its way around, and training your team to work alongside it add to your initial investment. This stage is crucial because a well-integrated AGV is a productive AGV.

Here’s what to anticipate:

- Setup and Integration: Merging the AGV with your existing systems involves technical expertise. Depending on the complexity, this could range from $5,000 to over $20,000.

- Training: Your team needs to know how to coexist with these machines. Training sessions could add another $2,000 to $5,000 to your initial expenses.

Customization Costs:

Not all AGVs fit all needs right out of the box. Sometimes, you need it to do something a little extra or work a bit differently. Customizing your AGV to meet specific needs—like carrying odd-shaped items or navigating tricky paths—can add to your costs. Think of it as ordering a custom suit; it fits your needs perfectly, but it’s going to cost more than off-the-rack.

This can widely vary, but custom features can easily add 10-20% or more to the base price of your AGV.

Budgeting for AGVs: What You Need to Think About

Adding AGVs to your operation isn’t just about the purchase; it’s about making a smart investment that pays off. Let’s walk through what to keep in mind to ensure you get the most value out of every dollar spent.

Identifying Your Needs:

First things first, what do you need your AGV for? Whether it’s moving light packages or heavy metal parts, the load capacity can greatly affect the price, from $40,000 to $200,000. Consider the environment it’ll operate in too—does it need to handle extreme temperatures or navigate through tight spaces? And flexibility—is it a one-trick pony, or can it adapt to different tasks? Pinning down these details will help you zero in on the type of AGV that best fits your operation without overpaying for unnecessary features.

Planning for the Future:

Think big picture. Today’s needs might not be tomorrow’s. Opting for an AGV system that can scale with your business is crucial. This might mean choosing a system that’s easily upgradable or can integrate with future technologies. It’s about not just meeting current demands but preparing for future growth and changes, ensuring your investment remains valuable long-term.

Total Cost of Ownership:

Upfront costs tell only part of the story. Remember, operational costs (maintenance, energy, software updates) and installation can add significant expenses. When comparing options, consider the total cost of ownership over the AGV’s lifespan to understand the real value it brings to your operation. Sometimes, a higher initial price might offer lower long-term costs, making it the smarter choice financially.

Exploring Financial Aids:

Finally, don’t overlook potential financial aids. Grants, incentives, and financing options can make a big difference in affordability. Some manufacturers or local governments offer programs to encourage technological upgrades, which can help offset the costs of integrating AGVs into your workflow.

Choosing the Right AGV: It’s Not Just About the Money

Picking an AGV for your operation goes way beyond just looking at the price. It’s about ensuring it fits like a glove in your current setup, will be there for you when things get tough, keeps everyone safe, and comes highly recommended. Let’s dive deeper into what makes an AGV the right choice for you.

Compatibility:

First up, can the AGV easily chat with your current machines and software? It’s like inviting a new friend to a tight-knit group—they need to get along with everyone. Compatibility is key to avoid costly changes to your existing setup. Ensure the AGV can integrate smoothly with your infrastructure, avoiding any unnecessary tech headaches.

Reliability and Support:

An AGV is a big investment, so you want one that’s reliable and backed by a team ready to help. Look into the vendor’s reputation. Are they known for quality and durability? What about their service agreements? If something goes wrong, you’ll want quick and efficient support to minimize downtime. This peace of mind often justifies a higher price tag.

Safety First:

Safety isn’t just a nice-to-have; it’s a must. Your chosen AGV should be packed with safety features to protect your team and your products. It also needs to meet industry standards and regulations. This ensures not only the well-being of your staff but also keeps you clear of legal headaches.

User Reviews and Case Studies:

Finally, don’t take the vendor’s word for it. Look at Qviro’s reviews from other users and dive into case studies. These real-world stories can reveal a lot about how the AGV performs under pressure, its long-term reliability, and the vendor’s customer service. Learning from others’ experiences gives you a clearer picture of what to expect and can steer you towards the best choice for your needs.

Conclusion:

Investing in AGVs is more than just the price—it’s about how they fit into your operations and benefit you in the long run. The right AGV can streamline your workflow, reduce labor costs, and improve safety, but you need to consider more than just the initial cost. Think about how it integrates with your existing setup, whether it can handle your workload, and how much you’ll spend on maintenance, energy, and software updates over time. A cheaper option now could cost you more later. To make the best choice, get quotes, compare vendors, and learn from real-world case studies.