Industrial Robots are mechanical powerhouses that are not just about doing the heavy lifting; they’re about transforming the way you work. From boosting your production rates to ensuring each product is of top-notch quality, robots are the silent heroes in the backdrop of modern manufacturing. If you’re on the hunt to enhance efficiency, safety, and save on costs, understanding the benefits of automation through robots is your first step.

Let’s dive into how this technology can redefine your production landscape.

What’s an Industrial Robot?

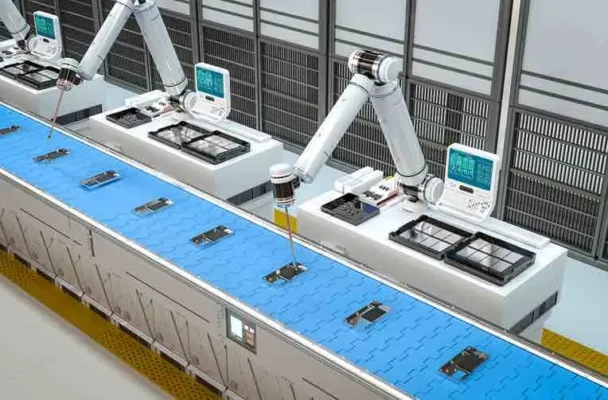

Industrial robots are high-tech helpers in your factory. A super-flexible arm that can move in all directions. It’s designed to mimic the movements of a human arm, with joints that can rotate and extend to reach different spots easily.

These robots are all about doing tasks faster and more accurately than humans can, especially the repetitive or risky ones. Whether it’s picking up heavy parts, assembling products, or even painting, they’ve got it covered. With their ability to be programmed for various tasks, they fit right into your manufacturing process, no matter what you make.

For you, this means your production line gets a big boost. You can produce more, reduce mistakes, and keep your workers safe from dangerous jobs. Plus, these robots can work day and night without a break, making sure your factory is always on the move. Getting one of these robots is like adding a super worker to your team, ready to take on any challenge.

How does an Industrial Robot Work?

At its core, an industrial robot is programmed to follow specific instructions. You tell it what to do through a computer program. Whether it’s picking up parts, assembling products, or packing them, the robot repeats these tasks with unmatched consistency. Its ‘brain’ – the controller – processes your commands, sending signals to the motors at each joint. These motors move the robot’s arm smoothly and accurately, ensuring it performs tasks exactly how you need. This means tasks are done faster and without mistakes.

Let’s get into the benefits of using an industrial robot:

10 Benefits of Using an Industrial Robot:

1. Increased Efficiency & Productivity:

An Industrial robot is equipped with joints like a human arm, moves quickly and never gets tired. It works 24/7, speeding up your work without any breaks.

Here’s the kicker:

it’s super accurate. Every task it does, it does perfectly, every single time. Whether it’s putting tiny pieces together or moving big items, it makes no mistakes. This means you waste less and get more perfect products.

What does this mean for you?

Faster production, lower costs, and better-quality items. It’s not just about keeping pace; it’s about leading the pack. With this kind of robot, you’re not just making small changes; you’re completely transforming how things are made.

2. Improved Quality & Consistency:

With its flexible, jointed arm, industrial robots handle tasks with a level of precision humans can only dream of. This means every product it touches turns out exactly the same, top-notch quality every time.

Why does this matter to you?

Well, it’s simple. When your products are consistently good, your customers notice. They get exactly what they expect every time they buy from you. No surprises, just reliable quality. This consistency builds trust and keeps your customers coming back.

And there’s more. These robots cut down on errors. Say goodbye to the costs and delays caused by defects. With the robot’s precision, your waste drops and your efficiency skyrockets. You’re not just saving money; you’re also making your production line greener by reducing waste.

So, what’s in it for you?

A reputation for quality, more satisfied customers, and a leaner, more efficient operation. That’s the power of bringing an industrial articulated robot into your team.

3. Enhanced Safety:

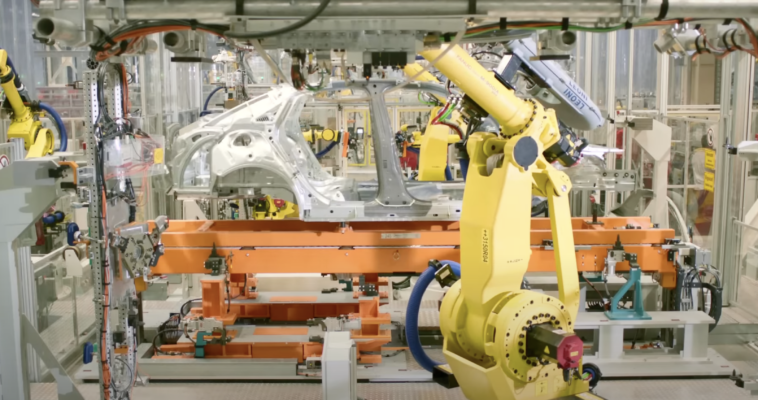

Industrial robots take on the risky jobs, keeping you and your team out of harm’s way.

Why is this a big deal for you?

Safety first, always. These robots can handle the dangerous stuff – working with hot metals, toxic substances, or heavy lifting – that could put you or your coworkers at risk. By stepping in to do these tasks, they significantly reduce the chance of accidents and injuries.

Not only do they keep people safe, they also create a more organized and efficient work environment. With robots handling the hazardous tasks, you can redesign your workspace for better safety and workflow. This means fewer obstacles and less clutter, making it easier and safer for everyone to move around.

A safer workplace leads to happier, healthier employees. It also means lower costs related to accidents and insurance. Plus, focusing on safety shows you care about your team, boosting morale and loyalty.

4. Reduced Operating Costs:

Industrial Robots are the heavy lifters that never call in sick or take a break, tirelessly working shifts.

These robots don’t just replace one aspect of the production process; they can take on multiple tasks. This versatility means you can save on additional machinery and the space it would occupy. Plus, their precision reduces waste materials, saving you even more money.

Think about maintenance and training costs, too. Once these robots are set up, they run with minimal downtime. The occasional maintenance they need is straightforward, keeping costs predictable and low. And training? Teach your team once, and these robots will follow the program flawlessly, reducing the need for constant retraining or supervision.

For you, this translates to a leaner budget. Lower labor costs, less waste, and more efficient use of space and resources. It’s about getting more out of every dollar you spend. In the long run, investing in industrial articulated robots means your production line is not just more productive, but also more cost-effective.

5. Flexibility & Scalability:

Today, the robot could be assembling car parts; tomorrow, it might be packaging them. All it takes is a change in programming, and your robot is ready for a new task. No need for new machines or long setups.

But there’s more. As your business grows, these robots grow with you. Starting with just one robot on a single task, you can scale up smoothly as demand increases. Add more robots, or reassign them to different tasks as needed. This scalability ensures that your production line can adjust and adapt quickly to new orders or changes in product design without missing a beat.

For you, this means your investment in robotics is future-proof.

Whether you’re ramping up production, diversifying your product line, or just looking for ways to work smarter, industrial articulated robots are your go-to solution. They offer the flexibility to adapt and the scalability to expand, making them invaluable assets in your quest for efficiency and growth.

6. Better Use of Space:

Industrial robots are compact powerhouses designed to operate in tight spaces. Unlike bulky machinery that demands large footprints, these robots maximize your existing space. Picture a robot with a flexible arm, capable of reaching over and around obstacles. It can work in corners or alongside humans without needing a safety cage.

For you, this means you can do more in less space. These robots can be installed on walls, ceilings, or tucked into small corners, turning previously unusable areas into productive zones. This is especially crucial if your facility isn’t massive. You won’t need to consider relocating or expanding physically to increase production. Instead, you maximize every inch of your current setup.

Moreover, the compact nature of these robots allows for closer placement to other machines or workstations. This reduces the distance materials need to be moved, streamlining your production process even further.

7. Enhanced Competitiveness:

Utilising industrial articulated robots puts you ahead in the manufacturing race. These robots work with precision and speed, making your production smoother and faster. This means you can deliver top-quality products quickly, standing out in a crowded market.

For you, this translates to meeting customer expectations for quality like never before. In a market that demands perfection, your ability to deliver consistently high-quality items sets you apart.

These robots adapt quickly to changes. Need to switch up your production for a new product or tweak an existing one? You can reprogram your robots fast, avoiding the usual delays of changing setups.

Quickly adapting robots give you an advantage. They let you seize new chances and adapt to changes easily. With these robots, your production speeds up, and your business becomes more flexible. You’re not just catching up; you’re leading the way.

8. Better Resource Management:

Using industrial articulated robots means you get smarter with your resources. These robots are super precise, so they use exactly what they need and cut down on waste. This is great for saving materials and money. It makes your production leaner and helps the planet too.

Here’s the deal: every action these robots take is spot on. This precision means you use just the right amount of materials, reducing waste. Less waste means you save more, not just in costs but also in environmental impact.

Plus, these robots can switch tasks without a hassle, making your production line more efficient. You get more done without needing more space or time.

For you, this means running a more cost-effective and eco-friendly operation. Adding these robots to your line isn’t just about doing things faster; it’s about doing them smarter and with respect for the environment. It’s a win for your wallet and the world.

Conclusion:

To sum it up, think of industrial articulated robots as your key to a whole new level of production. They speed things up, make tasks error-free, and adapt easily to whatever you throw at them. With these robots, you cut costs, keep workers safe, and use resources wisely. It’s about doing more, better, and faster. Embracing these robots means you’re not just keeping up with the times; you’re leading the charge. So, step into the future of manufacturing with industrial articulated robots and turn your production line into a model of efficiency and innovation.

Do you want to compare different Industrial Robots?

Join our community to connect with experts and discover how industrial robots can transform your production line! Join the Qviro Community

Are you looking for a System Integrator?