This article has important info about Cobot Risk Assessments, looking at possible problems with robots working together.

Skilled experts do it to follow the rules, keep the workplace safe, and make sure safety continues.

What is a Cobot Risk Assessment?

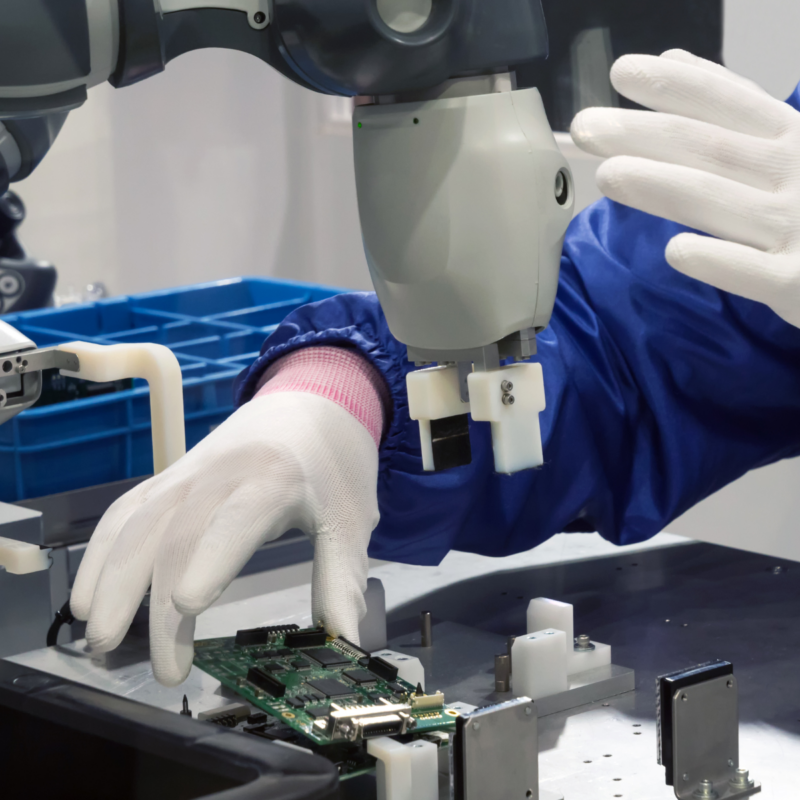

A cobot risk assessment is really important for safety where collaborative robots work. It helps find and cut down on dangers like collisions and getting tangled up. The assessment looks at the work area, how hard the tasks are, the cobot’s design, and how it works with people.

Once we know the risks, we do things to make it safer. This might be using safety gear or doing things in a different way. Doing this helps keep workers safe and makes sure companies follow the safety rules to keep workplaces secure.

How It’s Done:

Doing a cobot risk assessment has these steps:

1. Figure out what tasks the cobot will do.

2. Check for possible dangers in those tasks.

3. Use safety measures to control or get rid of those dangers.

Don’t forget, keep updating this assessment regularly to make sure it still works. There are standards like ISO 10218-1 and ISO/TS 15066 to help with this.

Doing this assessment is really important to keep the workplace safe, follow the rules, and prevent accidents.

5 Key Findings from a Risk Assessment:

1. Cobots’ Task-Related Risks:

This includes potential issues like getting trapped, collisions, entanglement, falling objects, electric shock, or fires.

2. Evaluating How Bad and How Likely the Risks Are:

Determine how risky and how likely these dangers are by considering factors like the work environment, task complexity, cobot design, and how humans and robots interact.

3. Managing Risks:

In this section, we explore ways to control or get rid of these hazards. We use safety devices, rules, or changes to how things are done.

4. Checking Safety Measures:

We measure how well our safety measures work to make sure they provide good protection.

5. Regular Updates:

It’s important to review and update our safety assessment regularly to keep it effective as things change and to make sure everyone stays safe.

Fulfilling Key Requirements:

Performing a cobot risk assessment fulfills several key requirements:

1. Meeting Safety Standards:

Conducting a cobot risk assessment ensures compliance with essential safety standards like ISO 10218-1 and ISO/TS 15066.

2. Legal and Ethical Responsibility:

It’s both a legal requirement and a moral obligation for employers to protect the health and safety of their employees.

3. Identifying and Mitigating Hazards:

This assessment is crucial for identifying and reducing potential dangers related to cobots.

4. Enhancing Safety Culture:

By promoting a safer work environment, it contributes to an improved safety culture within the organization.

5. Business Continuity:

Preventing accidents and injuries through risk assessment helps maintain business continuity by avoiding disruptions to operations.

Who Should Do the Cobot Risk Assessment?

A trained expert should do it. They need to know about cobots and how to find dangers with them. The right people for the job are:

1. Risk Assessor:

They know how to find and deal with problems at work.

2. Safety Engineer:

They can make safety plans and rules for the workplace.

3. Cobot System Integrator:

They are good at setting up, making software for, and looking after cobots.

4. Cobot Vendor/Manufacturer:

They can help with tech support, risk checks, and telling you about cobot safety stuff.

It’s important that the person doing the assessment is not involved in making, designing, or taking care of the cobots.

What Comes After the Risk Assessment?

After finishing the assessment, here’s what comes next:

1. Safety Measures:

Take steps to make things safe. This might involve using safety tools or changing how things are done.

2. Training:

Teach workers how to use cobots safely and what to do in emergencies.

3. Regular Checkups:

Keep an eye on things. We regularly look at the assessment and check that things are still safe.

4. Records:

Write down what we found in the assessment. This helps us remember what we did and show that we followed the rules.

5. Maintenance and Watching:

Make sure the cobot stays safe. This means taking care of it and keeping an eye on it.

6. Talking:

Talk to the people who need to know. This includes workers, bosses, and managers. We want everyone to know about the risks and how we’re keeping things safe.

Conclusion:

To sum it up, a Cobot Risk Assessment is really important for keeping workplaces safe. Trained experts look for dangers and stick to safety standards. They put safety measures in, train employees, and do regular checks to make sure the workplace stays safe.

Do You Need to Compare Different Cobot Models?