Robot Grippers are essentially the hands for robots, allowing them to pick up, move, and manipulate objects with ease. Whether you’re aiming to boost efficiency on your manufacturing line, enhance precision in assembly tasks, or simply streamline your operations, understanding robot grippers is key. This guide is crafted for you, the project engineers, to navigate the diverse world of grippers. We’ll explore what they are, how they work, and how to select the right one for your needs, ensuring you make an informed decision for your automation projects.

Understanding Robot Grippers:

Robot grippers are the crucial link between the digital and physical world in industrial robotics. They act much like human hands, giving robots the ability to interact with objects in their environment. This section breaks down the essence of robot grippers and how they transform robots from static machines into dynamic helpers.

What is a Robot Gripper?

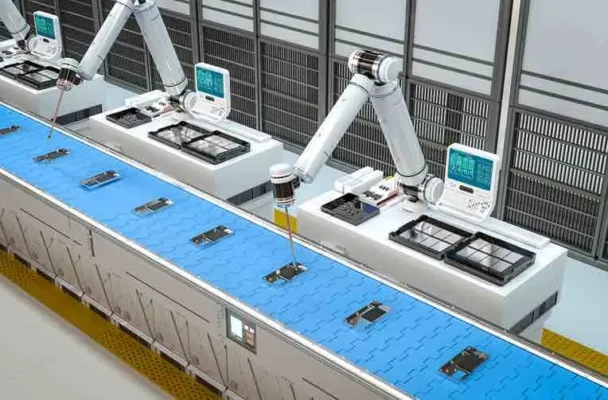

At its core, a robot gripper is a tool attached to the end of a robotic arm, designed to grasp and manipulate objects. Think of it as the hand at the end of a robot’s arm, equipped not with fingers and thumbs, but with specialized mechanisms that allow it to hold onto things. Grippers are the point of contact between the robot and the items it needs to handle, making them a critical component in a wide range of industrial applications.

The Role of Grippers in Robotics:

Robot grippers do more than just grab items. They’re designed to replicate the functionality of the human hand, including the ability to pick up, hold securely, and release objects. This ability is crucial for tasks ranging from assembling parts on a production line to sorting and packing products. By mimicking the versatility of human hands, grippers enable robots to perform complex tasks with precision and efficiency.

How Grippers Mimic the Human Hand:

The design of robot grippers is inspired by the human hand’s versatility and adaptability. While they don’t have fingers and palms, grippers achieve similar functionality through various means:

- Mechanical Grippers use fingers or jaws that can open and close around an object.

- Vacuum Grippers suck up objects with a vacuum, ideal for smooth and larger items.

- Magnetic Grippers utilize magnets to pick up metallic objects.

Each type is suited for different tasks, but all share the common goal of enabling robots to interact with the physical world in a way that’s reminiscent of human capabilities. By understanding the functions and mechanisms of robot grippers, you’re better equipped to select the right gripper for your automation needs, ensuring your robotic systems can handle tasks with the precision and care you require.

Types of Robot Grippers

In the world of industrial automation, robot grippers come in various shapes and sizes, each designed to perform specific tasks. Here’s a closer look at the most common types, showcasing their unique capabilities and ideal applications.

Mechanical Grippers:

How They Work: Mechanical grippers operate through a simple yet effective mechanism, typically using pneumatic or electric power to move their jaws or fingers open and close around an object.

Typical Uses: They shine in environments where precision and strength are required, such as handling metal parts, assembling components, and picking up rigid objects.

Advantages: Their straightforward design makes them reliable and easy to maintain, while their versatility allows them to handle a wide range of materials.

Vacuum Grippers:

How They Work: Vacuum grippers use suction power to hold onto objects. They’re equipped with a vacuum pump that creates a vacuum to adhere to the item’s surface.

Ideal Applications: Perfect for handling large, flat, or delicate items like sheets of glass, cardboard boxes, and even fragile components.

Why They’re Suitable: The lack of physical contact minimizes damage to delicate objects, making them ideal for tasks requiring a gentle touch.

Magnetic Grippers:

Functionality: Magnetic grippers use magnetic force to hold metallic objects. They can be either electro or permanent magnets.

Best Uses: They excel in handling ferrous metals without direct contact, useful in automotive and metalworking industries.

Efficiency in Specific Conditions: Magnetic grippers are highly efficient in environments where speed and precision are paramount, and where gripping from the side is not feasible.

Soft Grippers:

Introduction to Soft Robotics Technology: Soft grippers are made from flexible materials that can deform to match the shape of the object they are gripping.

Benefits: They are particularly useful for handling fragile items, irregular shapes, or when a delicate touch is needed.

Adaptability: Their ability to conform to a wide variety of shapes makes them versatile tools in industries like food processing and pharmaceuticals.

Expanding the Toolbox

Beyond these four main types, the robotic gripper toolbox is vast and varied:

- Hydraulic Grippers: Offer unmatched power for heavy-duty tasks.

- Pneumatic Grippers: Known for their speed and affordability, they’re a staple in many manufacturing processes.

- Electric Grippers: Provide precise control and feedback, suitable for tasks requiring delicate handling.

- Angular Grippers: Ideal for gripping objects at specific angles, enhancing precision in assembly tasks.

- Parallel Grippers: Their adjustable jaws make them suitable for a variety of shapes and sizes.

- Adaptive Grippers: Can alter their grip to handle a wide range of object shapes, offering unparalleled versatility.

- Palletiser Grippers: Specialized for efficient stacking and palletizing operations.

- Magnetic Grippers: Perfect for contactless handling of ferrous materials.

Each gripper type brings its unique strengths to the table, enabling engineers to tailor their automation solutions precisely to their operational needs. Whether dealing with delicate, irregular, or heavy-duty objects, there’s a gripper designed to meet the challenge.

Advice:

Pick grippers with smooth edges, not sharp ones, to make work safer. Consider this during risk assessments for collaborative robots to ensure safety.

Factors to Consider When Choosing a Robot Gripper

Selecting the right robot gripper isn’t just about picking a model off the shelf; it’s about matching the tool to your specific needs. Here are the key factors you should consider to ensure you make the best choice for your automation projects.

Application:

The task you’re automating is the starting point for choosing a gripper. Different applications require different gripper capabilities. For instance:

- Assembly: You might need a gripper that can handle small, precise movements.

- Packaging: A gripper that can adjust to various sizes and shapes could be crucial.

- Machine Tending: Look for durability and the ability to handle heavier loads.

Think about the items the gripper will handle. Delicate, irregular items? Sturdy, uniform parts? This will guide your choice.

Compatibility:

A gripper is part of a larger system. It needs to fit physically and technically with your robotic arm and the overall automation setup. Check for:

- Mechanical Fit: Does the gripper attach easily to your robot arm?

- Electrical and Software Integration: Can the gripper communicate seamlessly with your robot’s control system?

Ensure the gripper you choose can integrate smoothly into your existing setup to avoid unnecessary complications.

Environment:

The environment in which the gripper will operate influences your choice. Factors to consider include:

- Cleanrooms: You may need a gripper made from materials that don’t produce particles.

- Harsh Conditions: Look for grippers designed to withstand extreme temperatures, dust, or moisture.

Selecting a gripper suited to your environment ensures longevity and reliability.

Payload & Precision:

Finally, consider the weight and precision required for the objects your gripper will handle:

- Payload: Ensure the gripper can support the weight of the items you’re automating.

- Precision: For tasks requiring high accuracy, select a gripper designed for detailed work.

Balancing payload capacity with precision needs is essential for optimal performance.

By carefully considering these factors—application needs, compatibility, environment, and payload and precision—you’ll be well-equipped to choose the right robot gripper for your automation projects, ensuring efficiency and effectiveness in your operations.

Installing and Integrating Robot Grippers

Getting your robot gripper up and running involves more than just physical installation. It requires careful programming and calibration to ensure it operates seamlessly within your system. Here’s a straightforward guide to help you through the process.

Attaching the Gripper:

Step 1: Selection and Preparation

- Ensure the gripper you’ve chosen is compatible with your robot arm in terms of size, weight, and interface.

Step 2: Physical Installation

- Securely attach the gripper to the robot arm. This might involve bolting or clamping the gripper in place, depending on the design.

- Connect any necessary cables or hoses for power and control. Make sure they are properly routed to avoid interference with the robot’s operation.

Step 3: Safety Check

- Once installed, perform a thorough check to ensure everything is secure and that there are no loose parts or wires.

Programming and Calibration:

Understanding the Software

- Familiarize yourself with the robot’s control software. This is where you’ll program the gripper’s operations.

Programming the Gripper

- Input the specific commands or actions you want the gripper to perform. This could include open, close, grip strength, and more.

- Utilize any programming tools or wizards provided by the gripper or robot manufacturer to simplify this process.

Calibration for Optimal Performance

- Calibration is crucial to ensure the gripper operates accurately. This might involve setting the gripping force, speed, and range of motion to match the specific objects you’ll be handling.

- Test the gripper with various objects to confirm it’s performing as expected. Adjust the calibration as necessary.

Integration Testing

- Run the gripper as part of the overall robotic system to ensure it works well with other components and operations.

- Pay attention to timing, synchronization, and the handoff of objects between the gripper and other parts of the system.

By following these steps for installing, programming, and calibrating your robot gripper, you can achieve a smooth integration into your manufacturing process. This ensures your automation system operates efficiently, safely, and effectively, meeting your production needs with precision.

Maintenance and Safety Tips for Robot Grippers:

To make sure your robot grippers work well and safely, it’s important to keep them maintained and follow safety rules. Here’s a simpler guide on how to do just that.

Maintenance Made Easy:

Check-ups: Look over the gripper often for any damage or loose bits to avoid any surprises.

Cleanliness: Keep it clean from dust and anything that shouldn’t be there, using safe cleaning stuff.

Lubrication: Some grippers need a bit of oil to keep things moving smoothly, so apply it as the maker suggests.

Software Up-to-date: Keep the software fresh to get new features and fixes, ensuring it plays nice with other equipment.

Safety First:

Proper Training: Make sure anyone using the grippers knows how they work and how to use them without risks.

Emergency Stops: Have a clear way to quickly stop the gripper if things go wrong, with easy-to-reach emergency buttons.

Keep a Safe Distance: Use barriers or sensors to keep people safe from the gripper’s moving parts, especially where people and robots are working close by.

Follow the Rules: Pick grippers that meet safety rules and standards, showing they’re safe to use at work.

Safety Checks: Regularly check how safe the workplace is around the grippers, looking for any dangers or ways to make things safer.

Following these straightforward steps for maintenance and safety will help your robot grippers do their job well while keeping everyone safe around them. Keeping up with care and sticking to safety rules is key to a productive and safe workplace.

Conclusion:

Collaborative robots and their grippers make manufacturing flexible and efficient. By thinking about the things we talked about in this guide, you can choose the best gripper. This helps your automation work better, faster, and safer. So, use grippers to make your robot do amazing things in manufacturing.

Want to dive deeper into the world of robot grippers and connect with experts? Join our community at Qviro Community for comprehensive insights and support tailored to your automation needs!