Exploring Autonomous Mobile Robots (AMRs) for your warehouse? You’re not alone. AMRs are changing the game in automation, helping with everything from carrying goods to keeping tabs on your inventory. But let’s talk about what matters most to you: cost. What will an AMR set you back? We’re here to help you understand the price tag, giving you the details you need to decide if an AMR fits your budget.

Let’s get started.

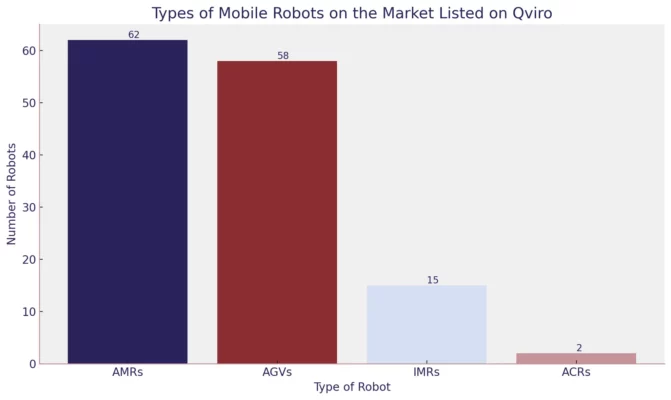

What Types of Mobile Robots are Available on the Market?

AMRs: Autonomous Mobile Robots

AMRs are the smart movers. They navigate on their own, avoiding obstacles and deciding the best routes as they go. Perfect for carrying goods around in warehouses or factories without needing a set path.

AGVs: Automated Guided Vehicles

AGVs follow fixed routes, usually marked on the floor or by wires. They’re great for repetitive tasks where the route doesn’t change, like moving materials from one point to another along a predetermined path.

IMRs: Industrial Mobile Robots

IMRs are the heavy lifters, designed for tougher environments and tasks. They can handle larger loads and are often used in manufacturing settings where moving big items or materials is a daily task.

ACRs: Autonomous Cleaning Robots

ACRs keep your floors clean. They roam around, sweeping or mopping, making sure your spaces are spotless. Ideal for maintaining cleanliness in large areas like warehouses, shopping centers, or airports.

Each type of mobile robot has its specialty, from smart navigation and heavy lifting to following set paths and cleaning. Choose the one that fits your needs the best.

Curious about finding the best AMR that suits your needs and budget? Check out Alina on Qviro to compare prices and features of various AMRs. Alina makes it easy to see which options align with your requirements, helping you make an informed decision.

In this article, we are going to focus mainly on AMRs and learning all about it.

What are the Main Applications of an Autonomous Mobile Robot?

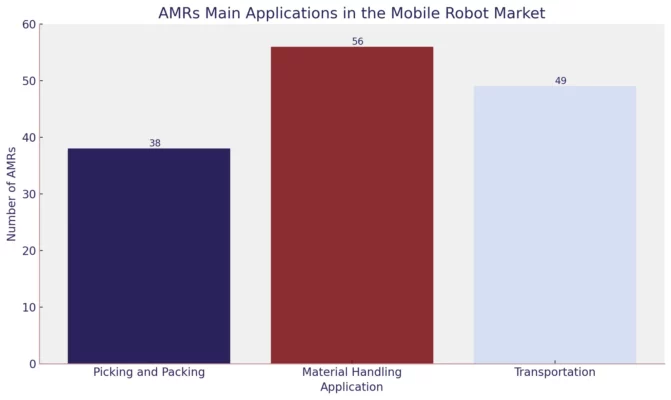

Based on our study of over 62 AMRs listed on Qviro in the Mobile Robot market, we’ve pinpointed the three main applications that businesses like yours are using AMRs for. Let’s dive in.

1. Material Handling:

Topping the list, material handling is the most popular use for AMRs, with 56 out of the 62 models designed for this purpose. AMRs excel at moving materials from one spot to another within your facility. Whether it’s delivering components to assembly lines or transporting finished goods to the storage area, AMRs handle these tasks with ease, making your operations more efficient and your workers’ jobs easier.

2. Transportation:

The second most common application, found in 49 of the AMRs we studied, is transportation. This goes beyond just shifting materials; it’s about relocating goods throughout your entire facility. From shipping docks to inventory shelves, AMRs can navigate complex routes, ensuring that products get to where they need to be, quickly and safely.

3. Picking and Packing:

Finally, picking and packing is another major role for AMRs, with 38 models dedicated to these tasks. In the fast-paced world of order fulfillment, speed and accuracy are key. AMRs streamline the picking process by retrieving items for orders and assisting in the packing process, reducing errors and increasing throughput. This is especially valuable in e-commerce and retail distribution centers, where meeting customer demands swiftly is crucial.

What Affects the Price of an AMR?

Curious about what goes into the cost of an Autonomous Mobile Robot (AMR)? Let’s break down the main factors that determine how much you’ll need to invest.

Size & Complexity:

Bigger and more complex AMRs come with a higher price tag. If you need an AMR that can carry large loads or navigate complicated routes, be prepared to pay more. These robots have advanced sensors and software to handle challenging tasks, which adds to their cost.

Capabilities:

What your AMR can do also plays a big role in its cost. Need one that can pick and pack, or handle delicate items? Or maybe you want an AMR that can work outdoors? The more specialized the tasks, the higher the cost. This is because more sophisticated technology and programming are required to meet these specific needs.

Brand & Compatibility:

The brand of AMR you choose can affect the price. Well-known brands might offer more advanced features but at a higher cost. Also, consider how the AMR fits with your current systems. Choosing an AMR that easily integrates with your existing setup can save you money in the long run.

Setup & Maintenance:

Don’t forget about the costs beyond buying the robot. Setting up your AMR and keeping it running involves extra expenses. This includes installation, training for your team, and ongoing maintenance. Some AMRs are designed for easy setup and low maintenance, which can help keep costs down.

Understanding the Full Cost of an AMR:

When you’re thinking about adding an AMR to your team, it’s not just the sticker price you need to consider. Let’s break down the costs so you know what you’re getting into.

Initial Purchase Price:

The first thing you’ll notice is the price tag. AMRs can range from $10,000 for smaller models to up to $100,000 for the larger, more complex ones. The cost depends on the size, capabilities, and technology of the robot. So, think about what tasks you need the AMR for and choose accordingly. It’s like picking a car – the more features you want, the more you’ll pay.

Operational Costs:

Once you’ve got your AMR, the spending doesn’t stop. Just like any machine, AMRs need upkeep. This includes regular maintenance to keep them running smoothly and software updates to ensure they’re using the latest tech. Plus, your staff might need training to work with these robots. These costs can add up over time, so it’s important to budget for them.

Hidden Costs:

Here’s where it gets tricky. There are costs you might not think about right away. For example, if your operations change and you need the AMR to do something new, you might have to pay for system reconfiguration. Also, as your business grows, you might need more robots or different models, which means more money. And don’t forget about any extra equipment or changes to your workspace to accommodate the robots. These hidden costs can surprise you, so it’s good to keep them in mind.

What’s the Real Cost? Calculating AMR’s Total-Cost-of-Ownership:

When you’re thinking about getting an AMR, the price tag is just the beginning. Let’s talk about Total Cost of Ownership (TCO) and why it’s a big deal.

Why TCO Matters:

TCO is like the full story of what your AMR will cost over its lifetime. It’s not just about how much you pay upfront; it’s about understanding all the costs that come up while you own it. This includes ongoing costs like maintenance and unexpected ones like upgrades. Knowing the TCO helps you see the bigger picture and make smarter decisions.

How to Calculate TCO:

To figure out the TCO of your AMR, start with a simple formula:

TCO = Initial Purchase Price + Operational Expenses + Hidden Costs

- Initial Purchase Price: This is how much you pay to buy the AMR. Easy enough, right?

- Operational Expenses: Think about the costs to keep your AMR running. This includes regular maintenance, software updates, and training for your team.

- Hidden Costs: These are the costs that might surprise you. Need to change your AMR’s tasks or get more robots as you grow? What about extra equipment or tweaks to your workspace? Add these to the mix.

Add up these three parts, and you’ve got your AMR’s TCO. It’s a straightforward way to make sure you’re considering everything, not just the initial expense. This way, you can plan your budget better and avoid any surprises down the road.

TCO Example: Breaking Down the Numbers

Let’s put the TCO formula into action with a simple example. Imagine you’re considering an AMR with a range of capabilities suitable for your needs.

Initial Purchase Price: $50,000

This is the amount you pay to get the AMR into your warehouse.

Operational Expenses (over 5 years):

- Maintenance: $2,000/year

- Software Updates: $1,000/year

- Staff Training: $3,000 (one-time)

Total Operational Expenses = $2,000 * 5 + $1,000 * 5 + $3,000 = $25,000

Hidden Costs (over 5 years):

- System Reconfiguration: $5,000

- Additional Equipment: $4,000

Total Hidden Costs = $5,000 + $4,000 = $9,000

Calculating TCO:

TCO = Initial Purchase Price + Operational Expenses + Hidden Costs

TCO = $50,000 + $25,000 + $9,000 = $84,000

So, over the course of 5 years, the TCO for your AMR is $84,000. This calculation helps you understand that the real cost goes beyond the initial $50,000 investment, incorporating ongoing and unexpected expenses to give you a comprehensive view of what to expect financially. This insight allows you to plan better and ensures that you’re fully prepared for the investment you’re making.

Getting the Most Out of Your AMR Investment:

Investing in an Autonomous Mobile Robot (AMR) is a big step toward optimizing your operations. Here’s how to ensure you’re making the most of every dollar spent.

Pick the Perfect Match:

Start by choosing an AMR that fits like a glove with your needs. Not all AMRs are created equal; some excel in navigating complex environments, while others might be better suited for heavy lifting. Consider what tasks you need automated most and pick an AMR designed for those jobs. It’s like choosing a vehicle—there’s no point in getting a sports car if you’re going off-roading. A well-suited AMR can enhance efficiency without unnecessary features inflating the cost.

Grow Smartly with Scalable Solutions:

Your business isn’t static, and your automation solutions shouldn’t be either. Opt for AMRs that can scale with your growth. This might mean choosing robots that can easily integrate with additional units or ones that can be upgraded as technology advances. Scalability ensures that your initial investment continues to pay off even as your needs change, preventing the need for a complete overhaul down the line.

Tap into Financial Support:

Don’t overlook potential financial aids. Many governments and industry organizations offer grants and incentives to encourage businesses to adopt automation technologies. These can significantly lower the initial cost of implementing AMRs in your operations. Doing a bit of research or consulting with an expert can uncover opportunities for financial support, making the leap into automation more accessible and less burdensome on your budget.

Conclusion:

Thinking about boosting your business with AMRs and other cool automation tech? Check out Qviro.com for all the info you need to get started. Want advice that fits just your business? Our experts are ready to help. Contact us for a personal assessment and a quote that matches your specific needs. Let’s work together to upgrade your operations.

Do you want to compare different Mobile Robots?