If you’re aiming to improve your manufacturing line with a cobot but need to stick to a budget, you can still find great options under $10,000. Designers build cobots to work safely alongside humans and they can significantly boost efficiency.

This guide will help you understand what to look for in a budget-friendly cobot and how to choose one that fits your specific needs without breaking the bank.

But before we begin…

What is a Cobot?

A cobot, or collaborative robot, is a type of robot designed to work alongside humans in shared spaces. Unlike traditional robots that often need safety cages, cobots come with advanced sensors and software that let them safely interact with people. This feature makes them extremely useful in industries ranging from manufacturing to healthcare.

Key Features:

Safety: Cobots are equipped with sensors that help them detect the presence of humans and adjust their actions to avoid injuries. This feature allows them to be deployed in environments where human interaction is frequent.

Flexibility: They are versatile and can be easily moved and reprogrammed to perform different tasks. This flexibility helps businesses adapt to changing production needs without significant downtime.

Ease of Use: Cobots are user-friendly. They often come with intuitive interfaces, so even those without programming experience can operate them. This opens up robotics to a broader range of workers, enhancing productivity and innovation.

Applications:

Cobots are transforming industries by taking on repetitive tasks, such as assembly, packing, machine tending, and inspection. This not only speeds up production but also frees up human workers for more complex and creative tasks, boosting both efficiency and job satisfaction.

4 Important Factors to Understanding Your Needs:

1. Why It Matters?

Before you dive into buying a cobot, it’s crucial to pinpoint what you need it for. Each cobot has its strengths and might not fit every situation, so understanding your specific requirements ensures you get the most out of your investment.

2. Identify the Application:

What job do you need automated? Cobots excel in various roles:

- Machine Tending: They can load and unload machines quickly and consistently.

- Packaging: Cobots are great for repetitive packing tasks, enhancing speed and reducing human error.

- Assembly: They can precisely assemble parts, improving product quality and worker safety.

Knowing which tasks you want to automate helps narrow down the choices to models that excel in those specific areas.

3. Consider the Parts:

What materials will your cobot handle? The nature of the parts affects which cobot you should choose:

- Metal Parts: Require robust cobots with precise handling capabilities.

- Boxes: Lighter-duty cobots can manage, but need the right end-of-arm tooling.

- Sensitive Materials: Look for cobots with delicate touch and fine control to avoid damage.

4. Safety & Integration:

Safety is crucial. Make sure the cobot you select has the necessary sensors and safety features to protect your team. Also, consider how easily the cobot integrates with your existing systems. Compatibility with your current tech stack minimizes disruptions and speeds up implementation.

Featured Cobots Under $10,000:

Choosing the Right Cobot:

When your budget is capped at $10,000, you must choose your cobot strategically. The key criteria? Price, functionality, and real user reviews. Let’s dive into a couple of standout options that deliver great value without breaking the bank.

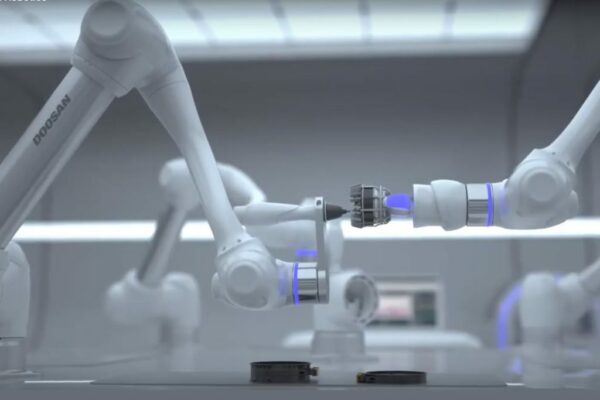

Doosan M0609:

The Doosan M0609 is known for its plug-and-play simplicity and user-friendly programming. It’s a versatile choice, well-suited for tasks like sanding and assembly. Users praise its reliable performance and the quality of support, though its color options are limited. Despite its higher end of the budget, its consistent high marks for safety and maintenance make it a worthy investment for those needing a robust and adaptable cobot.

Franka Emika Panda:

For a slightly more advanced option, the Franka Emika Panda is known by it’s users for its precision and safety features, making it ideal for educational and research environments where flexibility and safety are paramount. It handles delicate tasks well, thanks to its fine control capabilities. Though it’s on the pricier side and has a lower payload, the Panda’s intuitive user interface and compatibility with various programming environments, such as ROS and MATLAB, make it a favorite among those in academic and light industrial settings.

Each of these cobots brings something unique to the table, offering a balance of cost, ease of use, and functional adaptability. Choosing the right one starts with understanding your specific needs and reviewing what other users have to say about their experiences.

Doosan M0609: A User-Friendly Cobot for Versatile Applications

The Doosan M0609 cobot stands out in the sub-$10,000 category for its exceptional balance of performance and price. Known for its compact design, this cobot is specifically engineered for small and medium-sized applications including sanding, assembly, and machine tending.

It offers the advantage of a straightforward, plug-and-play setup, which means you can integrate it into your production line without needing extensive modifications or specialized training. Pricing varies depending on the vendor and the specific configuration but typically stays within the budget-friendly range, making it an accessible option for many businesses.

User-Reported Strengths:

Ease of Use: Users consistently highlight the M0609’s user-friendly nature. Its intuitive programming interface allows even those with minimal robotic experience to get the cobot up and running quickly. The ability to teach the robot through simple movements and commands means that your team can adapt and optimize operations without complex coding knowledge.

Safety Features: Safety is a standout feature for the M0609. Equipped with advanced sensors and responsive software, the cobot can detect the presence of human workers and adapt its movements to avoid accidents. This makes it an ideal choice for environments where human-cobot collaboration is frequent.

Maintenance: Another point of praise is the cobot’s reliability and ease of maintenance. Users report high uptime with minimal intervention needed, ensuring that production runs smoothly with fewer stops and starts.

User-Reported Weaknesses:

Compatibility: Some users have noted challenges with integrating the M0609 with other equipment. While it excels in standalone tasks, its compatibility with external systems and third-party tools can sometimes require additional configuration, which might not always be straightforward.

Market Presence: As Doosan is relatively newer in the cobot market compared to brands like Universal Robots or KUKA, some users feel the ecosystem of compatible accessories and support options is not as extensive. However, the company is rapidly expanding its presence and support network.

Franka Emika Panda: Precision and User-Friendly Cobot for Academics

The Franka Emika Panda stands out for its precision and versatility, making it ideal for academic and research settings. It features 7 degrees of freedom, mimicking complex human arm movements. Typically priced under $10,000, the Panda is an affordable choice for detailed, precision-based tasks, offering great value to universities and research facilities.

User-Reported Strengths:

Safety: The Panda is built with safety in mind, equipped with sensitive torque sensors in each joint to detect human contact and prevent injuries. It’s designed to work closely with humans, automatically stopping or adjusting its path to ensure safety.

User-Friendly GUI: The Panda’s graphical user interface is simple and intuitive, making it easy for users to program and operate the robot. Its straightforward controls and ability to save task presets make it accessible even to those new to robotics, reducing setup time and the learning curve.

Academic Applications: The Panda excels in academic environments where precision and adaptability are required. It’s commonly used for tasks that need fine motor skills, such as delicate assembly or handling sensitive materials. Its compatibility with educational platforms like ROS (Robot Operating System) makes it a preferred choice in universities worldwide.

User-Reported Weaknesses:

Limited Payload Capacity: One notable limitation of the Franka Emika Panda is its relatively low payload capacity, restricting it to handling only lighter objects. This can be a significant drawback in industrial settings where handling heavier materials is necessary. The Panda’s design prioritizes precision and safety, which somewhat limits its utility in more demanding physical tasks.

Compatibility Issues: Users have also reported some difficulties with integrating the Panda with heavier-duty or non-standard equipment. While the cobot is well-suited for academic and light industrial environments, its compatibility with a broader range of industrial tools and machines is not as extensive. This can lead to challenges when trying to incorporate the Panda into more complex automation systems.

High Cost: Despite its advanced capabilities, the cost of the Franka Emika Panda is relatively high, especially when considering its payload and compatibility limitations. This price point can be prohibitive for smaller institutions or businesses that might benefit from its advanced features but cannot justify the investment given the specific operational constraints.

A Detailed Comparison:

The upfront cost of a cobot like the Doosan M0609 or Franka Emika Panda can be high. However, you should also factor in setup expenses such as extra hardware, software, or necessary modifications. Ensuring your new cobot integrates easily with your existing systems without needing costly changes can help keep initial costs under control.

Performance in Specific Applications:

Doosan M0609: This cobot shines in small to medium assembly, sanding, and machine tending tasks. It’s designed for versatility within a production line, capable of handling a variety of simple and complex tasks with relative ease.

Franka Emika Panda: Best suited for precision tasks in academic and light industrial settings, the Panda excels in applications requiring fine motor control and delicate handling, such as in laboratories or intricate assembly environments.

Ease of Use & Programming Flexibility:

Doosan M0609: Known for its plug-and-play setup, the M0609 offers straightforward programming that makes it accessible to operators without extensive technical backgrounds. Its intuitive interface allows quick adjustments and minimal downtime for reprogramming.

Franka Emika Panda: With a user-friendly GUI and compatibility with advanced programming environments like ROS, the Panda is ideal for users seeking flexibility in programming for complex research or detailed tasks. It also supports kinesthetic teaching for easy task demonstration.

Maintenance & Support Services:

Doosan M0609: Users report high reliability and easy maintenance, ensuring that production is not frequently interrupted. Support is readily available, although the global reach of Doosan’s service network is growing.

Franka Emika Panda: While generally reliable, the Panda’s more sophisticated technology may require specialized support, which is readily provided by Franka Emika. However, users might find the high-tech nature slightly more challenging to maintain on their own.

Safety Features & Certifications:

Doosan M0609: It includes advanced safety features that comply with current industrial safety standards, making it safe for close interaction with human operators. Its sensors effectively prevent accidents by detecting human presence and adjusting its operations accordingly.

Franka Emika Panda: Safety is a paramount feature of the Panda, equipped with high-sensitivity torque sensors and an operational design that prioritizes human-robot collaboration safety. It’s well-suited for environments where interaction is frequent and safety cannot be compromised.

Making the Decision:

Understanding the Total Cost of Ownership:

Choosing the right cobot goes beyond just the sticker price. You need to consider the total cost of ownership, which includes the initial purchase, setup costs, and ongoing maintenance. This approach helps you find a cobot that fits your budget and delivers value throughout its lifetime.

Initial Purchase & Setup:

The upfront cost of a cobot like the Doosan M0609 or Franka Emika Panda can be substantial, but it’s also crucial to consider the setup expenses. This includes any additional hardware, software, or modifications needed to integrate the cobot into your existing systems. Ensuring your new cobot can be integrated smoothly without requiring extensive or costly alterations will keep the initial financial impact manageable.

Ongoing Maintenance & Support:

Regular maintenance is crucial for reducing operational costs over time. Choose cobots known for their reliability and easy maintenance. Also, check the availability and cost of replacement parts. A cobot with easily accessible parts and support will minimize downtime and cut long-term costs.

Compatibility & Community:

Before finalizing your purchase, check the cobot’s compatibility with your existing equipment. A mismatch here can lead to additional costs or reduced efficiency. Also, consider the community and ecosystem surrounding the cobot. A strong user community and developer ecosystem mean better support, more available integrations, and a wealth of shared knowledge that can help you optimize your cobot’s use.

Conclusion:

Cobots priced under $10,000 can greatly improve your manufacturing efficiency and flexibility. Make sure to carefully consider your specific needs and thoroughly research before making a purchase. For in-depth reviews and examples of cobots in action, visit Qviro’s Cobot Category. Explore your options, read user feedback, and find the right cobot for your operations at Qviro.com. Make a well-informed decision to maximize your investment.

Do you want to compare different Cobots?