Heading into 2024, your manufacturing world is changing fast, thanks to new automation trends. If you want to keep your production smooth, cut costs, or beat the competition, it’s key to know what’s coming. Think smart robots working alongside humans, AI making decisions, and everything connected through the Internet of Things.

This guide focuses on the top 10 automation trends reshaping manufacturing in 2024.

Ready to see how these changes can make a big difference in your work?

Let’s get started.

1. Smart Factories and Industry:

In 2024, your factory can leap into the future with Industry 4.0 and smart factories. Think of a place where every machine and sensor talks, sharing data instantly. This is not just about machines working faster; it’s about them working smarter, together.

Your factory becomes a hub of efficiency with the Internet of Things (IoT). Machines predict their own maintenance needs, avoiding unexpected downtime. This means less waiting, more doing, and savings on costs that you didn’t even plan for.

The push behind this? A blend of robotics, data crunching, and augmented reality, all making your factory not just automated, but also intelligent. The aim? To boost your efficiency and keep you ahead in the game.

“Here’s a fact: By 2025, half of all factories will use IoT to connect and share data. This shift is essential, not optional, if you want to lead in innovation and operational success. – Oracle, 2024”

So, as 2024 unfolds, stepping up to smart factories and Industry 4.0 is crucial for your success. It’s about making your operations not just faster, but smarter and ready for tomorrow’s challenges.

2. Sustainability and Carbon Neutrality:

In 2024, going green is crucial for your factory. It’s all about making your operations eco-friendly without sacrificing efficiency. This move is not just about following trends; it’s about ensuring your manufacturing processes protect the planet while still keeping up with production demands.

Your role in cutting down greenhouse gases is vital. By choosing cleaner practices and renewable energy, you’re not just following rules; you’re setting a new standard. This shift doesn’t only benefit the earth; your customers and partners will notice and appreciate it too.

Carbon neutrality is the big goal. Already, “42% of Fortune Global 500 companies are aiming for major climate goals by 2030”. This shows that lowering emissions is not just the right thing to do; it’s essential for staying competitive. Every decision, from the energy you use to the materials and processes you choose, reflects this commitment.

Embracing sustainability and carbon neutrality means embedding these values deeply into your business. It’s about innovating for a better future, making sure your manufacturing doesn’t just meet today’s needs but also contributes to a sustainable world.

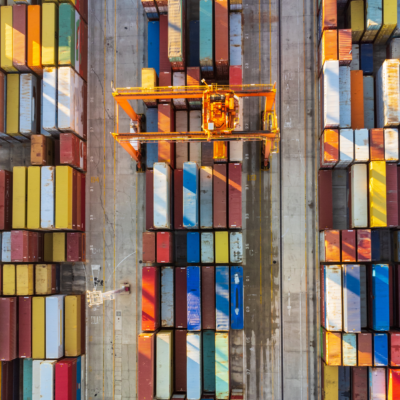

3. Reshoring for Supply Chain Resilience:

Bringing your manufacturing closer to home, or reshoring, is a smart move for your supply chain. Why? It’s all about making your operations more reliable and less dependent on far-flung suppliers. This shift can mean fewer delays, better quality control, and a stronger connection with your local market.

Reshoring helps you dodge the headaches of global supply chain disruptions. Think about it: shorter transport routes mean quicker turnaround times for your products. Plus, when your manufacturing is closer, you can keep a closer eye on quality, ensuring your customers get the best.

This trend isn’t just about avoiding problems; it’s about seizing opportunities. Reshoring can boost innovation by keeping you closer to your research and development activities. It also means you’re investing in your local economy, creating jobs, and building goodwill in your community.

“With over 364,000 reshoring jobs announced in 2022, a 53% increase from the previous record”, it’s clear that reshoring is more than a trend—it’s becoming a key strategy for manufacturers aiming for resilience and growth.

4. Workforce Development & Reskilling:

Upgrading your team’s skills is not just beneficial; it’s essential. As your factory embraces new technologies, your workforce needs to keep up. This means focusing on development and reskilling. Why? Because the tech in your factory is evolving, and so should your team’s abilities.

Facing a tech shift, your workers must learn new skills. This isn’t just about keeping jobs; it’s about creating a stronger, more versatile team. By investing in training, you’re not just upskilling your team; you’re showing them they’re valued. This boosts morale and loyalty, making your factory a better place to work.

“With 2.1 million manufacturing jobs predicted to be unfilled by 2030”, the stakes are high. The gap isn’t just a number; it’s a wake-up call. Your response? Launch reskilling programs. These programs aren’t just classes; they’re a bridge to the future of manufacturing. They turn challenges into opportunities, equipping your team for tomorrow’s roles.

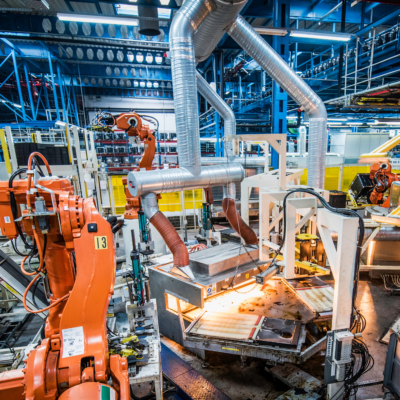

5. Rise of Collaborative Robots (Cobots):

Cobots are transforming your factory floor. These clever robots work alongside your team, improving both productivity and safety. What makes cobots a must-have? They’re user-friendly and adapt easily to your needs, making them a perfect fit for any task you have in mind.

Cobots are designed to be compact, versatile, and simple to program. Whether it’s assembling products, painting, or conducting inspections, cobots get the job done with minimal setup time. This flexibility means you can quickly adjust to new tasks, keeping your production line agile.

One of the biggest benefits of cobots is their built-in safety features. They can detect when someone is nearby and automatically slow down or stop to prevent accidents. This ensures your employees can work closely with cobots without any risk, promoting a safer workplace.

Cobots not only make your operations smoother but also positively impact your finances. They take over repetitive tasks, freeing up your staff to focus on more complex challenges. This not only increases your output but also enhances job satisfaction among your team.

When it comes to cost, cobots offer significant advantages. They’re more affordable than traditional robots and offer quick returns on investment by boosting efficiency and minimizing downtime.

The demand for cobots is skyrocketing, with the market projected to reach “$8 billion by 2030”. This growth indicates a wide recognition of their value across various industries, highlighting their role in enhancing adaptability, efficiency, and overall growth.

Integrating cobots into your factory in 2024 positions you as a leader in manufacturing innovation. It’s a strategic move to enhance your capabilities, ensure employee safety, and stay competitive. Cobots are more than just a trend; they’re the key to a more efficient, safer, and cost-effective operation right now.

6. Digital Twins for Enhanced Decision-Making:

Digital twins are changing how you plan and decide in your factory. Imagine having a virtual copy of your production line or machinery. This copy, or digital twin, uses real data to mimic your operations exactly. It lets you see how changes would play out in real life, without any risk.

Here’s the simple breakdown: Your machines are equipped with sensors that gather data. This data feeds into the digital twin, keeping it up-to-date with your physical setup. Want to test a new process? You can do it in the digital twin first. This way, you can avoid potential problems and see which ideas will actually work well.

Digital twins help you in big ways. They cut down on unexpected machine stops because you can predict issues before they happen. They also let you try out innovative ideas safely in the virtual world. Plus, they save you money by making your operations leaner and more efficient.

Using digital twins means you’re not just following tech trends. You’re using advanced tools to make smarter decisions, improve your factory’s output, and stay ahead of the competition. It’s a forward-thinking move that puts you in control of your manufacturing future.

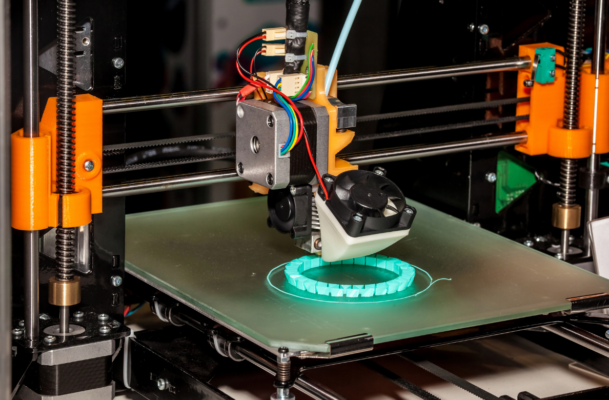

7. Advanced Manufacturing:

Stepping up your game with advanced manufacturing processes is key for your factory. These new methods, like 3D printing and precision machining, are all about making things better and faster. They change the game by improving how products are made, offering you a chance to do more with less.

Take 3D printing as an example. It lets you turn designs into real parts quickly, cutting down on waste and saving time. This method is not just about saving money; it’s about getting your products out there faster and offering custom options that were hard to do before.

Then, there’s precision machining. It ensures every part you make meets high-quality standards, fitting perfectly every time. Plus, using new, stronger materials means your products can be lighter and more eco-friendly.

These advanced techniques open up new possibilities. You can make products that last longer, work better, and have less impact on the planet. It’s about pushing boundaries and setting new standards in your industry.

By bringing these advanced processes into your factory in 2024, you’re not just following the latest trends; you’re leading them. You’re not just making things; you’re making them smarter, faster, and more sustainable. It’s a bold move towards a future where your factory is at the forefront of innovation, ready to tackle new challenges and exceed expectations.

8. AI & Machine Learning Integration:

Integrating AI and machine learning into your factory is a huge upgrade. These technologies are transforming the way you understand and optimize your manufacturing processes. By harnessing AI and machine learning, you’re not just collecting data; you’re unlocking insights that drive smarter decisions and more efficient operations.

Here’s how it changes the game for you: AI can predict maintenance needs, preventing costly downtime before it happens. Machine learning algorithms analyze patterns in your production data, identifying ways to increase efficiency and reduce waste. This means you can spot problems before they affect your bottom line and find opportunities for improvement that you might have missed.

But it’s not all about fixing issues. AI and machine learning also enhance product quality. They monitor and adjust manufacturing conditions in real-time, ensuring that every product meets your high standards. This level of precision and adaptability was unthinkable just a few years ago.

Moreover, these technologies make your factory more agile. You can quickly adapt to new market demands and changes in production without missing a beat. It’s like having a crystal ball, giving you insights into future trends and helping you stay ahead of the competition.

9. Supply Chain Optimization:

Technology is your best ally in optimizing your supply chain. It’s all about making your operations smoother, faster, and more reliable. By embracing tech solutions, you’re not just moving products; you’re streamlining the entire journey from supplier to customer.

Here’s what this means for you: With advanced tracking systems, you can see where your materials are at any moment. This visibility helps you anticipate delays and adjust plans on the fly, ensuring you meet deadlines without a hitch.

But it doesn’t stop with tracking. Predictive analytics come into play, analyzing trends and patterns to forecast supply chain disruptions before they occur. Imagine knowing a supplier might face shortages weeks in advance, giving you plenty of time to find alternatives. This level of foresight is a game-changer, keeping you one step ahead of potential issues.

Technology also simplifies inventory management. Automated systems keep track of stock levels, alerting you when it’s time to reorder. This means you’re never caught off guard by a sudden shortage or overstock, balancing your inventory perfectly.

10. 3D Printing’s Growth:

3D printing is changing the game in manufacturing. It’s making everything faster, more personalized, and even eco-friendly. For your factory, this means stepping into a world where making complex items is quicker and cheaper.

Here’s why 3D printing is a big deal for you: It cuts down the time it takes to turn a design into a real product. Imagine moving from a computer model to a physical part in just a few hours. This rapid turnaround is a huge plus, letting you keep up with fast-changing market needs.

Customization gets easier, too. With 3D printing, creating products tailored to individual customer preferences doesn’t cost you a fortune. This ability to customize on-demand can set your business apart, offering something truly unique.

And there’s a bonus: 3D printing is kinder to the planet. It uses materials more efficiently, cutting down on waste. Plus, you can choose from a range of environmentally friendly materials.

Conclusion:

In 2024, keeping up with these top manufacturing trends is key to leading in your industry. Trends like 3D printing and AI are changing the game. They make your factory smarter and quicker, ready for what’s next. By using these technologies, you’re not just following others; you’re ahead, driving change. For more on how to bring these innovations into your factory, check out Qviro.com. It’s your resource for leading-edge industrial automation insights.

IT has become the main driver for the development and simplification of technological processes, including in industrial production. Technical innovations in artificial intelligence, AR, IoT, quantum computing, GreenTech and Deep Tech are now optimising the system for developing digital business models and helping to streamline workflows. Today, the latest IT ideas make it possible to accurately calculate the cost of delivery after registration, create a wide range of different possibilities that simplify the planning of logistics processes, and even provide an opportunity to anticipate certain types of risks. This can be seen in the B2B-Integrationsplatform von Shipstage https://shipstage.com/integrations. Together, these innovations and digital business models provide an excellent foundation for the industry in 2024 and beyond.

Good article. I’ve been filming industrial manufacturing videos for years now – mostly filming the manufacturing process as a comms / sales tool to investors. Keep up the good work!