Programmable Logic Controllers (PLCs) are like strong computers made for tough places, working well in wet or hot areas. In PLC programming, two important parts are the user program and the operating system. Think of the user program as a recipe guiding the PLC on what to do.

In a PLC program, there are two main parts to consider: the user program and the operating system. The user program is similar to a recipe for the PLC’s tasks.

Operating System:

Think of the operating system as the boss of the PLC, in charge of arranging tasks and giving instructions to the PLC’s “brain,” called the CPU. However, it doesn’t directly supervise these tasks.

Here are a few things the operating system does:

1. It runs the user program, which is like the PLC’s to-do list.

2. It sets up a communication link for the PLC to talk to other devices.

3. It manages memory areas where important data is stored.

Why the User Program in PLC Operations are Important:

Think of the user program as a step-by-step guide for the PLC, carefully designed to tell the PLC how to do its tasks. Once you create this “guide,” it’s like sending the instructions right into the PLC’s brain, which is called the CPU.

Now, let’s see what the user program does:

1. It guides the PLC, like a chef timing tasks.

2. Checks signals from switches and sensors for information.

3. Directs the PLC to send signals, like turning on lights or motors.

4. Handles surprises and fixes mistakes for smooth operations.

3 Types of PLC Programming Methods:

When making robots or machines do things, there are different ways to tell them what to do. Programming is the important part, where you make a step-by-step list of instructions. Now, let’s look more into the interesting world of PLC programming.

PLC programming has two main groups:

1. Textual Language: This includes instruction lists and structured text.

2. Graphical Forms: This group has ladder logic (LD), function block diagrams (FBD), and sequential function charts (SFC).

When thinking about PLC programming, you have various methods to choose from. Some common ones are Ladder Logic (LD), Function Block Diagram (FBD), and Structured Text (ST). Each method gives a different way of programming, but don’t worry—they’re not too hard to understand. This makes automation easy for many people.

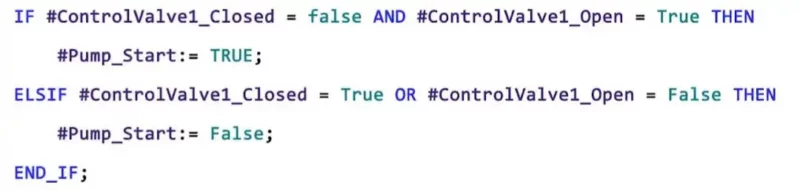

1. Structured Text (ST):

As we mentioned earlier, Structured Text falls into the category of textual languages.

Think of Structured Text programming like teaching a robot to speak a clever language. It’s mainly used for solving tricky math problems, kind of like helping the robot with its homework.

For example, you can use Structured Text to make the robot do math calculations, make choices based on certain conditions (like if it’s raining or sunny), and make the robot repeat actions, like taking small steps over and over again.

So, remember, Structured Text is part of the group of languages we talked about earlier. It’s like giving the robot a super-smart way to understand and solve math challenges.

Advice: In many cases, you don’t need any fancy PLC programming software to write Structured Text. Because it’s all about text, you can create your project in a plain text file, just like writing a letter or a note. Then, all you have to do is copy and paste it into your PLC project. It’s as easy as that!

Structured Text

Why Structured Text is Great for Beginners:

1. No PLC Programming Experience Required:

Structured Text is incredibly beginner-friendly. You don’t need any prior experience in PLC programming. It’s like learning a new language from scratch, and it explains itself as you go along.

2. Text-Based Simplicity:

One fantastic thing about structured text is that it’s just like writing a regular letter or note. You can create your project in a simple text file, no need for fancy software or complex file formats. Once your project is written down, you can easily copy and paste it into your PLC project. It’s straightforward and hassle-free!

3. Efficient & Lightweight:

As mentioned earlier, structured text is all about using text-based commands, which means it doesn’t require heavy graphics or take up much memory. This makes it a perfect choice for processors with limited memory capacity. You can achieve a lot without overloading your PLC.

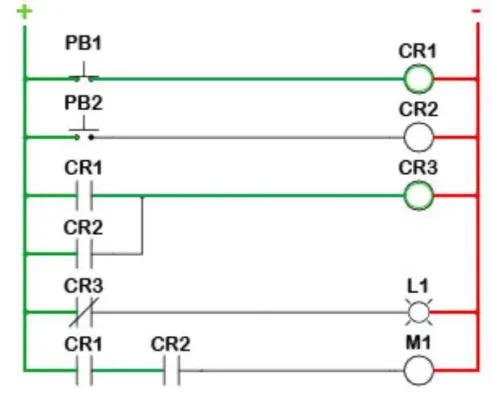

2. Ladder Logic (LD):

a. A Visual Language:

Ladder Logic, often shortened to LD, is a picture-based language in PLC programming. It borrows ideas from circuit diagrams and relay logic hardware. Picture it like making a map for your PLC to follow. Instead of using words or numbers, it uses symbols and lines to show different actions and connections.

b. Electrically Inspired:

Ladder Logic is closely connected to the world of electrical control wiring. It’s like talking in the language of circuits. When you create a Ladder Logic program, you’re basically explaining to the PLC how to deal with electrical signals and make decisions based on them.

c. Symbolic Simplicity:

This way of programming shares logical operations using symbols, meaning using symbols to show actions. Ladder Logic has ready-made functions, like a toolbox, each made for specific jobs. Think of it as having a set of building blocks to build your automation solutions. These functions have set limits based on the specific jobs they are used for.

Starting with Ladder Logic?

When you’re new to PLC programming, Ladder Logic is a great choice. Here’s why:

1. Visual Clarity:

It uses symbols resembling circuits, making it easy to follow.

2. Sequential Flow:

Logic goes from left to right, simplifying understanding.

3. Real-World Fit:

It’s ideal for applications involving real-world electrical control.

4. Widespread Use:

Ladder Logic is widely used in industrial settings, giving it broad applicability.

For beginners, Ladder Logic is your friendly starting point in PLC programming.

Advantages of Ladder Logic:

1. Self-Explanatory:

Ladder Logic is like drawing a picture of the circuit you want to create. As you code it, you’re also creating the design documentation. It’s like writing down the instructions and drawing the blueprint at the same time.

2. User-Friendly:

Because Ladder Logic uses pictures and symbols, it’s easy for anyone, even if you’re not an expert in industrial circuits. It’s like telling a story with pictures instead of words.

3. Simpler Debugging:

Modern tools for Ladder Logic show you how the “power” flows through your program like an animated map. This helps you quickly spot problems and fix them. It’s like having a map with flashing lights showing you exactly where things went wrong.

Function Block Diagram

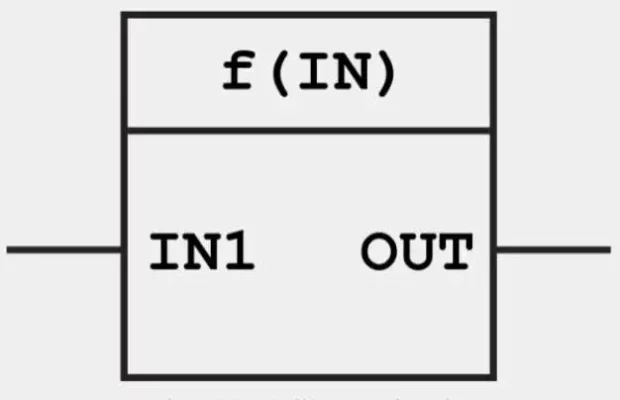

3. Function Block Diagram (FBD):

a. Block by Block Logic:

Function Block Diagram (FBD) is like solving a puzzle. It uses different logical blocks to process input and output information. The PLC (that’s like the brain of the machine) follows these blocks step by step to perform tasks.

b. Connecting Functions:

FBD is like connecting different pieces of a jigsaw puzzle. You take individual functions and link them together in a logical sequence to create a program. It’s a visual way of showing the PLC what to do.

c. User-Friendly Approach:

FBD is designed to be simple and easy to understand. Learning it is like learning to put together a simple puzzle. It’s a great choice for programming PLCs because it’s straightforward and graphical.

Advice:

1. Choosing PLC Software: When you buy a PLC, the company that makes it usually has software for programming it. You won’t miss out on anything if you use their software. But things are changing, as we mentioned before.

2. Beginner-Friendly Option: If you’re new to PLCs, consider trying Fanuc PLC Motion Control. It’s known for its ease of learning.y fancy PLC programming software to write Structured Text. Because it’s all about text, you can create your project in a plain text file, just like writing a letter or a note. Then, all you have to do is copy and paste it into your PLC project. It’s as easy as that!

Benefit of Function Block Diagram:

1. Reuse of Code:

Function Block Diagram (FBD) is like having a collection of building blocks. You can use these blocks over and over again in different parts of your program. When you use them, it’s like making a new copy each time. This way, you don’t accidentally erase or mess up the original data. It’s like having a set of Legos that you can use in many different projects. This helps reduce the chances of mistakes and makes programming faster and safer.

Conclusion:

Programmable Logic Controllers (PLCs) are tough computers designed for challenging environments, working perfectly even when it’s really wet or hot. The success of a PLC hinges on two things: the user program and the operating system. Understanding how these components interact and function is crucial, whether you’re just starting with PLCs or aiming to sharpen your skills. This knowledge is your key to mastering automation in any industrial setup.

Join our community at Qviro to connect with experts and explore more about Programmable Logic Controllers (PLCs) and how they can enhance your automation projects. Join Qviro Community