3D vision technology is a game-changer, especially if you’re looking to boost your manufacturing line’s efficiency. Understanding the costs involved is crucial for making smart investment decisions.

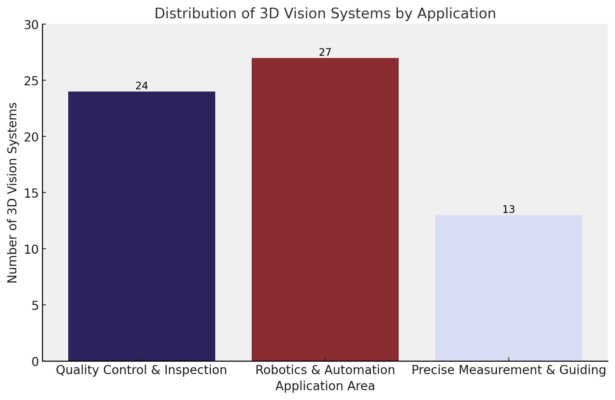

Whether you’re exploring options for quality control, robotics, or precise measurements, the price tag can vary widely. With 86 different 3D vision systems listed on Qviro.com, finding the right fit at a fair price can seem daunting.

This guide helps you understand the costs associated with 3D vision systems, focusing on leading options to ensure smart spending and enhanced production efficiency.

What is 3D Vision Technology?

3D vision technology lets machines “see” like humans. It uses cameras and sensors to create a digital model of the world in three dimensions. This tech helps machines understand the size, shape, and position of objects in real space, making them smarter and more adaptable.

How It Works:

3D vision technology gives your robot eyes that can measure everything around it in 3D. These “eyes” are actually cameras and sensors working together, capturing data about objects from different angles. The robot’s brain, or computer, then stitches these images together into a 3D model. This model lets the robot interact with objects accurately, whether it’s picking up a part or inspecting a product.

Applications in Industrial Automation:

3D vision technology is changing how we automate tasks, making processes more accurate and efficient:

- Precise Measurement & Guiding: This technology shines when accuracy is key. It helps place parts just right for assembly or guides machines for detailed work, like cutting or welding. This means everything fits together perfectly, every single time.

- Quality Control & Inspection: 3D vision lets automated systems check products from every angle, spotting any flaws with amazing accuracy. This helps make sure only the best products get to you, cutting down mistakes and boosting product quality.

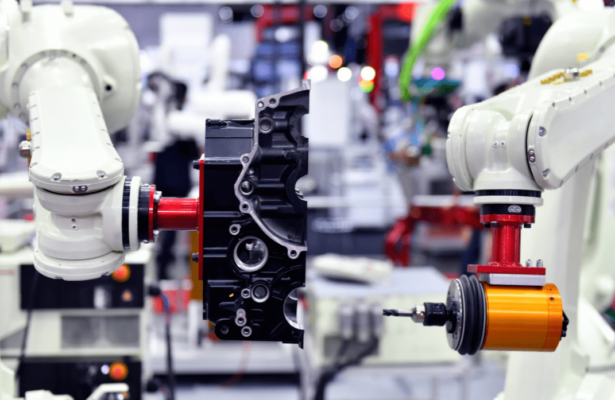

- Robotics & Automation: 3D vision gives robots the ability to see and understand their surroundings better. This means they can pick up and move items of all shapes, find their way in changing environments, or adjust to new tasks quickly, making them more flexible and effective.

Popular 3D Vision Systems and Their Pricing:

Pickit 3D’s Smart Solutions:

Pickit 3D offers automation solutions like depalletizing, bin picking, assembly, and surface treatment with 3D vision. These technologies aim to increase efficiency, lower costs, and improve workplace ergonomics, with prices ranging from EUR 19,800 to EUR 49,250. Each solution is designed to make manufacturing processes more flexible and smarter.

Compact and Precise: Pickit M-HD2

Pickit 3D offers a suite of 3D vision solutions tailored for industrial automation, with options ranging from the compact M-HD2 for small to medium objects to the L-HD for large field applications, featuring prices from EUR 10,150 to EUR 49,250. These systems are designed to enhance efficiency, precision, and ease of integration in manufacturing settings, also including an Edu Kit for educational use, making advanced 3D vision accessible across various applications and budgets.

Robust and Rapid: COGNEX 3D-A5000 Series

COGNEX 3D-A5000 Series: Get ready for rapid 3D scanning and high dynamic range imaging. Built to withstand tough industrial environments, it’s as sturdy as it is advanced.

With these standout options, pinpoint the right 3D vision system that aligns with your automation objectives and budget. Every choice here offers a way to sharpen your competitive edge, speed up your operations, and enhance your production quality. Ready to make your pick? Let’s get into the specifics and find the best fit for your factory floor.

Understanding the Cost of 3D Vision Systems:

When you’re diving into the world of 3D vision systems for your manufacturing or automation needs, the price can vary significantly. Let’s break down what you might expect to budget across different levels of system sophistication.

Entry-Level Systems

Starting from $3,000 to $10,000, entry-level systems are your go-to for straightforward tasks. Think about basic measurements, simple inspections, or spotting objects. They’re perfect if you’re after standard resolution and speed without all the bells and whistles.

Mid-Range Systems

With prices ranging $10,000 to $30,000, mid-range systems step it up with higher resolution, greater speed, and beefier processing power. These are ideal for more complex needs like detailed inspections, guiding robots with precision, or advanced measurement tasks that require a bit more from the technology.

High-End Systems

At the top of the tech tree, high-end systems, which can set you back $30,000 to over $60,000, are the heavy lifters. Featuring the highest resolution, rapid processing speeds, and the capacity to tackle the most complex applications (like high-speed robot guidance or precision metrology), these systems are for when you need the absolute best.

What Influences the Price?

- Hardware Complexity: More advanced sensors and processors bump up the price but offer better performance.

- Software Integration: Whether you opt for proprietary or open-source software, and how smoothly it fits into your existing systems, can affect the cost.

- Compatibility and Configuration: Needing extra tweaks to fit with your current setup? That could also influence the overall expense.

- Maintenance and Service: Consider the long-term care your system will need, as ongoing service requirements can impact total cost of ownership.

Choosing the right 3D vision system comes down to matching your specific needs with what’s on offer—and sometimes, investing a bit more upfront for a higher-spec system pays off in the long run. Always check with manufacturers or vendors to get the most accurate pricing for your unique requirements.

How to Choose Your 3D Vision Systems:

Choosing the right 3D vision technology is crucial for enhancing efficiency and quality in your operations. Let’s explore how to assess your needs and make a strategic selection to maximize value.

Assess Your Needs:

Understand Your Application: Before diving into options, pinpoint what you need the 3D vision system for. Is it for quality inspection, robotic guidance, or complex measurement tasks? Knowing this will help narrow down your choices.

Evaluate Your Environment: Consider the conditions under which the system will operate. Will it face extreme temperatures, dust, or moisture? The operational environment can significantly influence the type of system you need.

Consider Future Scalability: Think ahead. Will your chosen technology be able to grow with your business? Opting for a scalable solution can save you from future costs associated with replacing an inadequate system.

Total Cost of Ownership:

Upfront Costs vs. Long-Term Value: While the initial purchase price is important, consider the total cost of ownership (TCO). This includes maintenance, software updates, and potential upgrades. A system that’s slightly more expensive upfront but offers lower long-term costs can be more valuable.

Maintenance and Upgrades: Regular maintenance ensures your system operates efficiently and lasts longer. Factor in the ease and cost of potential upgrades, as future needs might require additional capabilities.

Integration and Compatibility: Choosing a system that integrates seamlessly with your existing setup reduces initial costs and potential headaches. Compatibility with your current machinery and software is a key factor in minimizing additional investment.

Making a strategic selection of 3D vision technology isn’t just about meeting your current needs—it’s about anticipating future challenges and opportunities. By carefully assessing your requirements and considering the total cost of ownership, you can select a system that offers the best long-term value for your operations.

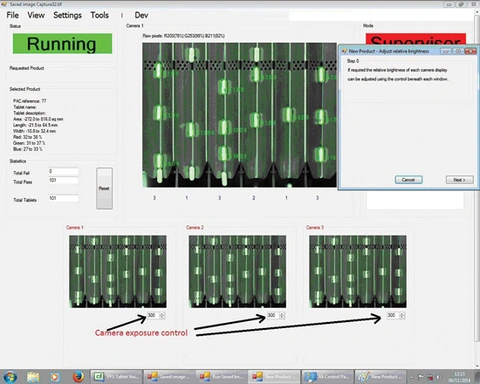

Success Story:

In the pharmaceutical industry, Machine Vision Technology developed a system for Pharma Packaging Systems that significantly improved the quality control process. By detecting partially formed and broken tablets and capsules, this system ensured accurate counting and reduced cross-contamination risks, leading to enhanced efficiency and error reduction in pharmaceutical manufacturing. This is a prime example of how 3D vision technologies can offer substantial value and ROI across different industries.

For more details about this success story, visit MVTec’s website.

Conclusion:

Looking into 3D vision technology could really make a difference in how businesses operate and ensure quality. There’s a lot to learn and benefit from. For those interested in getting into or improving their use of 3D vision, Qviro.com is a great place to start. It’s filled with reviews and studies on different 3D vision systems. Plus, if you need some advice on which system might fit your needs best, Qviro.com has a lot of resources and expert advice available.

Do You Want to Compare Different 3D Vision Systems?