In 2025, the world of welding is changing fast, thanks to cobots. These robots are designed to work right next to people, making welding jobs easier and safer in various industries. These cobots are easy to set up, can do many kinds of welding jobs, and work efficiently. This guide will show you the top 5 cobots that could really help your manufacturing line. We’ll make sure you choose the right tech to make your welding faster, more precise, and safer. Let’s explore the best cobots for your needs together.

What is a Cobot?

Cobots are robots that work with you, not just for you. They’re designed for safety and ease of use. You can quickly teach them tasks like assembly, packaging, or quality checks. They’re safe to use around your team, thanks to advanced safety features. Cobots are great for repetitive jobs, boosting your productivity. They’re affordable and don’t need complicated setups. Think of a cobot as a versatile helper on your production floor, making your job easier and more efficient.

What is a Welding Cobot?

Welding cobots are your solution for efficient and precise welding. These compact robots work right beside you, handling repetitive welding tasks with ease. They’re easy to set up and adjust for different jobs. With a welding cobot, your efficiency skyrockets, and you get consistent, high-quality welds. Plus, they’re built with safety in mind, keeping your workspace secure. Whether it’s spot or arc welding, a welding cobot fits seamlessly into your manufacturing process, boosting your productivity.

Find your welding cobot needs among the 277 options listed on Qviro.com.

Top 5 Cobots Best for Welding 2025:

1. ABB GoFa 10 & GoFa 12:

Qviro Score: 4.5/5

The ABB GoFa 10 and GoFa 12 models are exceptional for welding applications, offering precision and strength in tasks that require meticulous attention to detail. They’re a top choice in industries where welding accuracy and efficiency are paramount.

ABB GoFa 10 for Welding:

- Payload: This robot can handle welding tools and materials up to 10 kgs, suitable for various welding jobs.

- Reach: With an arm reach of 1.62 m, it can easily access different welding points on your workpieces.

- Design: The GoFa 10 thrives in challenging conditions, perfect for the harsh environments often found in welding. It withstands extreme temperatures and tough industrial settings, ensuring consistent performance.

- Usefulness: Ideal for continuous welding tasks, the GoFa 10 excels in precision and speed, making it a reliable asset in your welding processes.

ABB GoFa 12 for Welding:

- Payload: Can carry welding tools and materials up to 12 kgs, offering more versatility in heavier welding tasks.

- Reach: A slightly shorter reach of 1.4 m, but well-suited for more compact welding stations.

- Precision and Speed: Known for its exceptional precision (0.02mm) and rapid operational speed (2 m/s), the GoFa 12 is perfect for welding jobs that demand high accuracy and swift completion.

- Overall Performance: Both GoFa models stand out for their adaptability, robustness, and efficiency in welding applications. Their ability to perform precise, consistent welds makes them invaluable in enhancing your welding processes.

2. UR 20:

Qviro Score: 4.6/5

The Universal Robots UR20 is outstanding for welding applications, offering high precision and robustness for tasks that demand careful attention to detail. It’s a preferred option in sectors prioritizing welding accuracy and speed.

- Payload: This robot can manage welding tools and materials weighing up to 20 kgs, making it ideal for a wide range of welding tasks.

- Reach: It boasts an arm reach of 1,750 mm, enabling it to easily reach different welding points across your workpieces.

- Design: Designed for the demanding environments of welding, the UR20 operates efficiently even in extreme conditions. It’s built to endure high temperatures and tough industrial surroundings, assuring reliable performance day in and day out.

- Usefulness: Especially suited for extensive welding tasks, the UR20 stands out with its precision and operational speed, proving to be an indispensable asset in your welding operations.

With its ability to handle heavier payloads and its extended reach, the UR20 enhances your welding efficiency, offering remarkable precision and speed. Its robust design ensures it can withstand the rigors of industrial welding environments, making it a valuable addition to your welding process.

3. DOOSAN M-Series:

Qviro Score: 4.3/5

The DOOSAN M-Series robots are great for improving welding work. They are built to weld accurately and safely. This makes them a good choice for many different welding jobs. They help make welding better and safer for everyone.

- Payload: These robots can handle welding tools weighing up to 15kg, making them suitable for a variety of welding tasks.

- Reach: With a reach of up to 900mm, they can easily access different parts of the workpiece, ensuring thorough and precise welds.

- Collision Detection: High sensitivity collision detection ensures safe operation, reducing the risk of accidents and allowing for precise welding.

- Ideal for Compact Spaces: Their design makes them perfect for working in tight spaces, allowing for flexibility in welding operations across different environments.

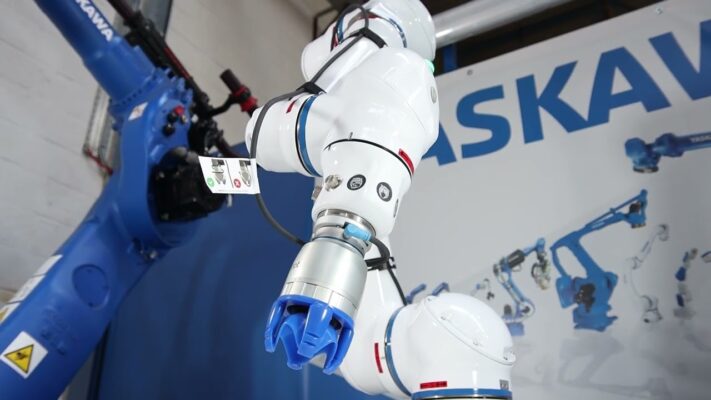

4. YASKAWA HC-Series:

Qviro Score: 4.7/5

The HC-Series emerges as a top-notch collaborative robot for welding alongside humans. Its adaptability and user-friendliness make it a prime choice for various welding tasks within the factory setting.

- Payload: With the capability to manage up to 25 kg, the HC10DTP Classic is ideal for handling a wide range of welding tools and components.

- Reach: Its extensive reach of 1889 mm allows it to cover a large working area, enabling it to perform welding tasks on large or complex assemblies efficiently.

- Welding Proficiency: This robot is engineered for precision in welding, delivering fast and accurate welds every time.

- Easy to Program: Programming the HC10DTP Classic is straightforward. Whether you’re a seasoned operator or new to robotics, you can easily teach it welding paths and patterns using hand guiding, a teaching device, or the intuitive Smart Pendant.

- Compact and Safe: The HC-Series robots are designed with numerous safety features, allowing them to retract or stop if a collision is detected, ensuring a safe working environment. Its compact size makes it a perfect fit for tight workspaces, facilitating safe and efficient collaboration between humans and robots.

5. FANUC CRX Series:

Qviro Score: 4.8/5

Tailored for welding tasks, the CRX-Series from FANUC transforms the way welding is done in compact factory spaces. Its user-friendly design and compact footprint make it an ideal choice for welding environments where space is at a premium. This robot series can handle various welding jobs, adapting quickly to different welding needs, thus enhancing productivity and making welding operations more efficient.

- Payload: Capable of handling welding tools and materials up to 10 kg, making it versatile for a range of welding tasks.

- Reach: With a reach of 1418 mm, it can easily access weld points on large or complex workpieces.

- Safety Features: Designed with safety in mind, the CRX-Series ensures a secure working environment for people working alongside it. This is crucial in maintaining workplace safety standards.

- Customization: The robot can be easily adapted for various welding applications, allowing for quick changes between different welding tasks without extensive downtime.

Conclusion:

In 2025, cobots are revolutionizing welding tasks with their safety, ease of use, and ability to collaborate with humans. Each cobot, from the versatile ABB GoFa series to the robust Universal Robots UR20, the compact DOOSAN M-Series, the user-friendly YASKAWA HC Series, and the efficient FANUC CRX Series, brings unique advantages to welding operations. When selecting a cobot, it’s crucial to consider its capacity, reach, and safety features to enhance welding speed, accuracy, and safety. This technological advancement marks a significant leap in robotic manufacturing.

Do You Need To Compare Different Welding Cobots?