ABB IRC5 Specifications

Ranked Nr. 8 of 85 Robot Software

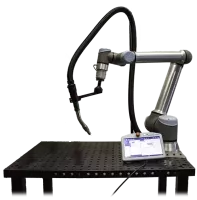

ABB's IRC5 is an advanced robot controller, known as the benchmark in robot controller technology. It stands out with unique motion control capabilities, offering flexibility, safety, modularity, application interfaces, multi-robot control, and PC tool support. The IRC5 can be easily integrated into various robotic systems, and its variants provide cost-effective solutions for different industries like automotive and electronics.

Safety is a key feature of IRC5, equipped with built-in safety functions like safety-rated stop and emergency stop. Its modularity allows easy maintenance and system upgrades, while supporting multi-robot control for seamless collaboration. The controller offers various application interfaces, including fieldbus and Ethernet, facilitating integration into diverse applications like material handling and painting.

Compatible with ABB's RobotStudio and third-party software tools, the IRC5 simplifies programming and simulation for robotics applications, reducing development time and costs. With its wide range of features and capabilities, the IRC5 is a versatile, high-performance choice for industrial automation, especially in demanding and safety-critical environments.

| Application |

|

| Software type |

|

| Industry |

|