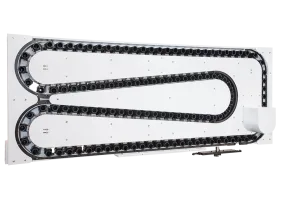

AGI Automation Components AGC-20 TOOL CHANGER Specifications

Ranked Nr. 54 of 116 End of Arm Tools

- Fail Safe - The locking mechanism remains locked even with a loss of pnumatic pressure.

- Handles High Moments as Extremely High Repeatability - The index pin gives Tool Chang Adapters the ability to handle radical moments, with high repeatablity +/- 0.001 in.

- Fast Coupling - The robot adapter can couple with the tool mounting adapter in less than 1/2 second.

- Low Deflection - The unique latching mechanism pulls the tool adapter into the robot adapter body - preloading the toll mounting adapter for excellent rigidity.

- Coupling Window - The robat adapter pulls up the tool adapter, allowing the user to couple while up to 0.4" off the face of the tool mounting plate.

| Type |

|

| Product mass | 41.27 kg |

| Payload | 31.75 kg |

AGC-20 TOOL CHANGER Downloads

Agc 20 40 robot tool changer 1

You need to

register

to download this file.