AGS Gripper System Alternatives & Competitors

Ranked Nr. 48 of 235 Grippers

Top 10 Gripper System Alternatives

- Elephant Robotics Pneumatic Gripper Pro with Air Compressor

- Elephant Robotics Adaptive Gripper

- Elephant Robotics Pneumatic Gripper Pro without Air Compressor

- Elephant Robotics Electric Parallel Gripper

- FESTO Parallel gripper DHPS

- SCHUNK GAP

- AGS Gripper Fingers

- AGS Magnetic Gripper

- AGS Textile Gripper

- AGS Gripper with Jaw

- AGS Inner Bellows Gripper

Elephant Robotics Pneumatic Gripper Pro with Air Compressor

Payload 1kg | Angular | ParallelElephant Robotics' Pneumatic Gripper Pro with Air Compressor is an efficient and reliable solution for industrial automation processes that require precise gripping of objects. Driven by gas and working with a solenoid valve, this gripper is easy to control and offers excellent grip force.

The fingertip of the gripper can be customized and exchanged for users' secondary development, adding flexibility and versatility to its gripping capabilities. The gripper comes with an air compressor, making it a complete and convenient solution for industrial automation processes.

Elephant Robotics Adaptive Gripper

Payload 0.15kg | Angular | SoftThe Adaptive Gripper by Elephant Robotics is a versatile robotic end-effector that uses a soft and flexible material to adapt to the shape and size of the object being grasped. It is designed to be applicable to a variety of consumer robotic arms and can be controlled via serial communication.

The gripper is capable of automatically adapting to the width of the clamping object, making it easy to use and eliminating the need for manual adjustments.

The Adaptive Gripper also provides a variety of programming language control interfaces, which allows users to integrate it into their existing automation systems with ease. This makes the Adaptive Gripper suitable for a wide range of applications, such as pick-and-place operations in manufacturing, packaging, and logistics.

The unique and patented design of the Adaptive Gripper allows it to grip objects gently, minimizing the risk of damage or breakage during the handling process.

Elephant Robotics Pneumatic Gripper Pro without Air Compressor

Payload 1kg | Angular | ParallelElephant Robotics' Pneumatic Gripper Pro without Air Compressor is an innovative gripping solution that is designed to meet the needs of various industrial applications. Driven by gas and working with a solenoid valve, the gripper is convenient to control and operate.

The fingertip of the gripper can be easily exchanged for users' secondary development, providing a customizable and flexible gripping solution. The gripper's compact size and ease of use make it an ideal choice for industries that require efficient and precise gripping of objects. With Elephant Robotics' Pneumatic Gripper Pro without Air Compressor, users can enjoy reliable and customizable gripping solutions that meet their specific needs.

Elephant Robotics Electric Parallel Gripper

Payload 0.1kg | Angular | ParallelElephant Robotics' Electric Parallel Gripper is a versatile and reliable gripping solution that is perfect for a wide range of industrial applications. Its compact structure and multiple connecting holes allow it to meet various installation conditions, while also ensuring a stable and secure grip on objects.

The gripper supports both IO and serial port control, making it easy to integrate with various industrial robotic arms. With its advanced technology and user-friendly interface, the Elephant Robotics Electric Parallel Gripper is an ideal choice for any industry that requires efficient and precise gripping of objects.

FESTO Parallel gripper DHPS

ParallelFesto offers mechanical parallel grippers in various designs. They are suitable for internal and external gripping. Parallel standard grippers are suitable for handling a wide range of small parts in a clean environment. To absorb high forces, Festo offers sturdy gripper systems with a resilient T-slot guide for the gripper jaws. Sealed grippers are suitable for handling tasks in very dirty and demanding environments. The precise parallel gripper has gripper jaws with an impressive backlash-free roller bearing. The electric long-stroke gripper is an alternative to pneumatics.

SCHUNK GAP

Angular | Parallel2-finger angular parallel gripper with gripper finger actuation of up to 90° per jaw.

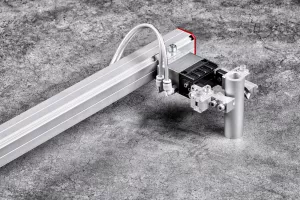

AGS Gripper Fingers

Angular | Parallel | RadialAGS Automation's Gripper Fingers, also known as GFI grippers, are designed to handle components that are too heavy for vacuum suction cups. When the demolding forces or handling weight are too great, these gripper fingers come in handy. They come in various sizes, with different finger shapes, to suit different components. The modular system of AGS Automation's gripper fingers offers a wide range of accessories that can be added to customize the gripper fingers to the specific application.

The functional range of AGS Automation's gripper fingers is diverse. The gripper fingers can be single-acting or double-acting, with or without self-locking. Single-acting gripper fingers are suitable for simple pick and place operations, while double-acting gripper fingers are useful for more complex applications that require additional control. The self-locking feature provides additional safety by locking the gripper fingers in place, preventing accidental release of the component.

AGS Automation's gripper fingers can be used in various industries, including manufacturing, logistics, and warehousing. They are particularly useful in applications that require picking and packing, material handling, and component assembly. AGS Automation's gripper fingers are compatible with a range of robotic arms and automation systems, making them a versatile solution for various automation applications.

In summary, AGS Automation's Gripper Fingers are a modular system of gripper fingers that can be customized with various accessories to suit specific applications. They are a good alternative to vacuum suction cups when handling heavy components, and they are compatible with a range of robotic arms and automation systems. They are best suited for industries that require picking and packing, material handling, and component assembly.

AGS Magnetic Gripper

Payload 3kg | MagneticAGS Automation's Magnetic Gripper, also known as MGR, is a perfect solution for handling ferromagnetic components with ease. This gripper is specially designed to handle weights ranging from 200g to 3000g per gripper. The magnetic gripper is available in both electrically and pneumatically driven versions to meet specific application requirements.

One of the most significant advantages of the magnetic gripper is its ability to provide reliable handling without the need for complex and expensive fixtures. It uses a magnetic force to securely hold the component in place, eliminating the need for mechanical clamping. This feature makes the magnetic gripper a perfect solution for applications that require fast and efficient handling of ferromagnetic components.

The magnetic gripper is equipped with a prism directly on the body that allows for easy attachment to PreciGrip profiles. This feature provides more flexibility in the gripping system's design, making it easier to integrate with other automation components. The magnetic gripper's modular design also enables easy maintenance, reducing downtime and increasing productivity.

AGS Automation's magnetic gripper is a versatile solution that can be used in a wide range of industries, including manufacturing, logistics, and material handling. Its ability to handle ferromagnetic components with ease and efficiency makes it an ideal solution for applications where speed, precision, and reliability are critical.

AGS Textile Gripper

Parallel | SoftThe AGS Automation Textile Gripper is a type of pneumatic gripper designed to handle soft materials such as textiles, insulating materials, woven fabrics, and sheet molding compounds. It uses needle grippers that are pneumatically driven to securely grip and handle these materials during various industrial automation processes, including cutting, sewing, and embroidery.

One of the key features of the AGS Automation Textile Gripper is its precision and accuracy. It is designed to grip delicate materials with extreme accuracy, ensuring that the material is not damaged or deformed during the handling process. This makes it a suitable option for use in high-end fashion or textile manufacturing where quality and consistency are essential.

The gripper also features a double-stroke mechanism that allows for greater control and precision in handling complex shapes and materials. This feature enables the gripper to make two different long movements, providing greater flexibility and precision in handling materials.

In addition, the AGS Automation Textile Gripper is designed to withstand extreme temperatures, making it suitable for use in harsh industrial environments. It is also compatible with a wide range of software systems, making it easy to integrate into existing automation workflows and processes.

Overall, the AGS Automation Textile Gripper is a versatile and precise solution for industrial automation processes that require the handling of soft materials. Its double-stroke mechanism, compatibility with various software systems, and ability to handle a wide range of materials make it a valuable option for textile and other manufacturing industries.

AGS Gripper with Jaw

Angular | Parallel | SoftAGS Automation's Gripper with Jaws, also known as GZA grippers, are designed to grip the sprue, which is the leftover plastic that is removed from a molded component. These grippers are commonly used in the plastic injection molding industry to remove the sprue from a molded part. However, they can also be used to grip the component itself, making them a versatile solution for a variety of gripping applications.

One of the main advantages of AGS Automation's Gripper with Jaws is the availability of different types of grippers. This allows for a custom fit for specific applications and component shapes. For example, there are grippers with curved jaws that can conform to the shape of the component, providing a secure grip. There are also grippers with straight jaws that can provide a firm grip on flat surfaces. These options provide a range of choices for different applications and can help optimize the performance of the gripper.

Another advantage of AGS Automation's Gripper with Jaws is that they can be a good alternative to parallel grippers. Parallel grippers work by moving the two jaws in parallel to each other to grip a component. However, in some cases, parallel grippers may not be able to provide a secure grip on irregularly shaped components. AGS Automation's Gripper with Jaws, on the other hand, can be designed with jaws that can conform to the shape of the component, providing a more secure grip.

In addition, AGS Automation's Gripper with Jaws can be customized with a range of features to meet specific application requirements. For example, grippers can be designed with spring-loaded jaws that can compensate for variations in component size or shape. They can also be equipped with sensors to provide feedback on the gripping force or the position of the component. These features can help improve the accuracy and efficiency of the gripping process.

Overall, AGS Automation's Gripper with Jaws provides a versatile and customizable solution for gripping applications in a range of industries. The availability of different types of grippers, as well as customization options, makes them a flexible choice for a variety of applications.