Applied Robotics QS QUICKSTOP™ COLLISION SENSORS FOR WELDING AND PLASMA CUTTING Alternatives & Competitors

Ranked Nr. 117 of 116 End of Arm Tools

Top 10 QS QUICKSTOP™ COLLISION SENSORS FOR WELDING AND PLASMA CUTTING Alternatives

- Bota Systems Medusa

- Bota Systems LaxONE

- Bota Systems MegaONE

- Bota Systems MiniONE Pro

- Applied Robotics QS QUICKSTOP™ COLLISION SENSORS

- ATI Industrial Automation Robotic Collision Sensors

- AGI Automation Components AGTC TOOL CHANGER

- ANUBIS 3D MTC-612 MANUAL TOOL CHANGERS (6 X 12MM)

Bota Systems Medusa

Product mass 0.11kgThe Medusa FT sensor from Bota Systems is a compact and lightweight force-torque sensor that is ideal for applications that require high sensitivity and precision. This all-in-one sensor has integrated signal processing electronics, a 6 DoF IMU, and temperature sensors, making it one of the smallest and most capable sensors in its class. The Medusa sensor is suitable for a wide range of applications, including the assembly of electronic components, rehabilitation and robotic-assisted surgery, and polishing and sanding in fine mechanics.

The Medusa sensor offers several key features and benefits:

- Ultra-low noise signal: Provides high precision measurements, even in challenging environments

- All-in-one design: Integrated electronics and sensors minimize the need for external components

- Compact and lightweight design: Weighing only 110 grams, it is easy to integrate into a wide range of systems

- Support for multiple software platforms: Includes software integration for ROS, LabVIEW, and MATLAB, making it highly compatible and easy to integrate

- 6 DoF IMU: Provides additional measurement capabilities and enhances the overall precision of the sensor

- Direct force and torque data: Outputs data in N and Nm for accurate and immediate analysis

- Embedded filtering, resolution, and sampling rate: Customizable for a wide range of applications

- Power supply range of 7-48 V (5V for Serial/USB): Supports a wide range of operating conditions

- Overload protection: Protects the sensor from damage in the event of excessive forces or torques

- Water-resistant and dustproof: Suitable for use in harsh environments

- CE compatible: Meets international safety standards

The Medusa sensor is compatible with the Meca500, and Bota Systems provides complete installation kits for easy integration. The sensor is also available with EtherCAT communication for additional capabilities.

Bota Systems LaxONE

Product mass 0.465kgThe Bota Systems LaxONE is an industrial-grade 6-axis force torque sensor that is designed to meet the demands of advanced applications in the robotics industry. With a lightweight construction and a payload capacity of up to 50kg, the LaxONE is ideal for use with robots that require end-of-arm tooling. The robust and stiff structure of the LaxONE makes it capable of withstanding high overload and cyclic load, while providing high sensitivity that makes it ideal for demanding applications such as sanding, polishing, deburring, precision assembly, and product testing.

The Bota Systems LaxONE offers the following features and benefits:

• All-in-One force torque sensor design

• ISO 9409-1-50-4-M6 mounting

• Compact and lightweight construction

• Embedded signal processing electronics

• 6 DoF IMU (available only with EtherCAT communication)

• 3 mounting flanges for 3D cameras and tools

• Measures on 6-axis

• Power supply of 7-48 V (5V for Serial/USB)

• Overload protection

• CE compliant

• Dustproof and water-resistant design

• Open-source software for TwinCAT, ROS, LabVIEW, and MATLAB®.

Bota Systems MegaONE

Product mass 1.386kgThe MegaONE is a compact and lightweight 6-axis force torque sensor designed for advanced industrial applications with robots that have a payload capacity of up to 120 kg. The sensor's robust and stiff structure can withstand high overload and cyclic load, while still providing high sensitivity, making it suitable for demanding tasks such as sanding, polishing, deburring, precision assembly, and product testing. With its integrated signal processing electronics, the MegaONE is easy to use and can be integrated into a variety of industrial robots, including those from ABB, Stäubli, Kuka, and more. The sensor also features a 6 DoF IMU for process monitoring and state estimation, as well as multiple mounting flanges for 3D cameras and tools.

Bota Systems MegaONE boasts the following features and benefits:

• An all-in-one force torque sensor design with ISO 9409-1-63-4-M8 mounting.

• Compact, lightweight construction for efficient utilization of robot payload.

• Embedded electronics for easy plug-and-play operation.

• A 6 DoF IMU for process monitoring and state estimation (only available with EtherCAT communication).

• 3 mounting flanges for 3D cameras and tools.

• Accurate 6-axis measurement.

• 7-48 V power supply (5V for Serial/USB).

• Overload protection for durability.

• CE compatibility.

• Dustproof and water-resistant design.

• Open-source software compatibility with TwinCAT, ROS, LabVIEW, and MATLAB®.

Bota Systems MiniONE Pro

Product mass 0.06kgThe compact and ultra-sensitive 6-axis force torque sensor with a signal noise of only 7mN is an impressive sensing system that has a range of applications in micro-robotics with haptic feedback. The low signal noise of the sensor ensures that the measurements are highly accurate and reliable, making it an ideal sensing system for applications that require precision and fine motor control. It is the smallest force torque sensor with integrated signal processing electronics and a 6 IMU.

MiniONE Pro is mechanically compatible with Mecademic Meca500 or Yaskawa MotoMINI, which are compact and highly precise robotic arms that are often used in micro-robotics applications. The combination of MiniONE Pro with these robotic arms enables telemanipulation, micro-polishing, and micro-assembly in various industries such as watchmaking, jewelry, and semiconductor manufacturing.

The haptic feedback provided by the force torque sensor allows the system or operator to feel the force and torque being applied by the robotic arm, making it easier to manipulate and control the micro-robotic tools. This feature is particularly useful in applications such as micro-polishing and micro-assembly, where the operator needs to have a fine level of control over the tools to achieve the desired results.

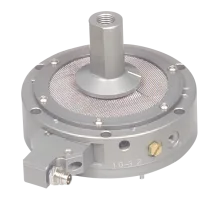

Applied Robotics QS QUICKSTOP™ COLLISION SENSORS

Product mass 0.11-16.8 kgThe QuickSTOPTM is a dynamically variable collision sensor that operates on an air pressure system – and provides excellent protection in machine load/unload robotics applications.

A regulated air supply provides positive, variable pressure to hold the collision sensor rigid during normal operation. At impact, the air chamber seal is opened, immediately signaling the system controller.

Advantages:

- Dynamically variable trip points

- Permanent repeatability

- Detects angular, rotational and compressive forces

ATI Industrial Automation Robotic Collision Sensors

Robotic Collision Sensor Features:

- High Repeatability: Following a collision, the use of precise locating components enables the Protector to reset to within 0.001 inches of its original position.

- Generous Range of Motion: During a crash the Protector can comply large distances in response to any type of crash (angular, axial or torsional) thus allowing the robot controller ample time to take corrective action.

- Rugged Design for Axial Compliance: The rugged design and construction of the Protector, with generous use of hardened tool steel in contact and wear areas, allows the unit to be used as an Axial Compliance Device for end-effectors. The unit can also provide angular and torsional compliance for certain applications.

- Energy Absorption: The impact energy generated during a crash is absorbed by a pneumatic chamber. This protects the tooling from being damaged by crashes. After absorption, this energy is redirected to automatically reset the device upon removal from the crash-causing object.

- Consistent Break-away Response: Break-away response is similar at a given pressure independent of whether the crash is angular, compressive axial, or torsional.

- Flexible Mounting Surfaces: Threaded and through hole mountings are provided for added flexibility. The simple mounting patterns reduce the stack height of the Protector and tooling assembly.

- Automatic Reset: After a crash, the Protector will self-reset when the robot removes the tooling from the crash situation. This eliminates the need to enter the robot cell to reset the crash protection device.

- Optional spring provides two trip points: Air pressure may be used to obtain a higher break-away point during high-inertia motion and the optional preset spring only for a lower break-away point. Inquire about the range of preset springs available for each model.

- Quick-Response Crash Detection: Nuisance tripping of the signal is avoided with the switch set to actuate at 0.020 inches of axial motion. A 3-Pin M8 Connector and cable are used to pass the crash signal.

- Field-rebuildable design (with prior customer training and special tools).

- Field-replaceable connector block assembly.

- IP 65 environmental protection rating (extra cost option).

AGI Automation Components AGTC TOOL CHANGER

Payload 90.72kg | Product mass 1.88kgThe AGTC Tool Changer line provides a strong and reliable method for a manipulator (i.e., a robot) to quickly change between different tools/end-effectors. With its modular design, we offer the maximum flexibility for any application.

OPTIONAL UTILITIES: 1. 4x M5 User Pneumatic Ports 2. Electrical Passthru (Signal, Communication, etc.) 3. Hardware Kit

ANUBIS 3D MTC-612 MANUAL TOOL CHANGERS (6 X 12MM)

Payload 80kg | Product mass 1.45kgThe MTC-612 is the largest manual tool changer in our line up and consists of 6 through-ports sized for G1/2 fittings which can be used for either vacuum or pressure. Customized robot flange plates ranging from 20-55mm and 80-100mm diameter patterns makes the MTC-612 a universal solution for your quick change needs.