Automation Technology MCS Series Specifications

Ranked Nr. 66 of 97 3D Vision Systems

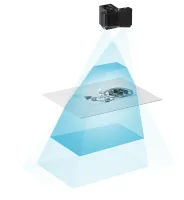

With the MCS series, our customers do not need to select pre-configured models, but can configure the solutions required for their applications themselves. The customer simply specifies the desired data such as height resolution, working distance, scan width (x-FOV), points per profile as well as laser wavelength and safety class and receives a 3D sensor composed of corresponding sensor, laser, and link modules. He gets this perfectly tailored solution for his measuring task without any extra cost or extra time, even as a single piece. Maximum flexibility without NRE charge – no other manufacturer in the world offers this.

Of course, the 3D compact sensors of the MCS series are factory calibrated and feature everything that is required for industrial use, from GigE Vision to 5 to 24 volt digital inputs and outputs to an RS422 encoder interface.

3D Sensor Module with GenICam 3.0 with Measurement Speed of up to 26 kHz at 4096 points/profile

As the first product of the new C6 series, AT integrates the new cx4090HS sensor module into the modular concept of the MCS series. This is based on a new sensor platform that supports the new GenICam 3.0 standard and thus implements additional, practical features such as MultiPart and MultiPeak. Users benefit not only from significantly more extensive functionality and more stable analysis capability, but also from faster application development. The profile speed is also significantly increased by new C6 platform, which is why the cx4090HS sensor module achieves a unique measurement speed of up to 26 kHz at a resolution of 4096 measurement points per profile.

| Protection (IP) | 67 |