COGNEX In-Sight 2800 Pricing & Product Details

Ranked Nr. 256 of 126 2D Vision Systems

In-Sight 2800 Pricing

Choose your model

In-Sight 2800 Overview

What is In-Sight 2800?

The COGNEX In-Sight 2800 vision system offers a powerful and flexible solution for factory automation applications. It combines artificial intelligence (AI) with traditional rule-based vision tools to handle a wide range of tasks, including presence/absence detection, sortation, and character reading. With optimized error detection, it enhances product quality by catching subtle defects, maximizes operational efficiency with intuitive job setup, and simplifies integration by automating image optimization.

One standout feature of the In-Sight 2800 is its unlimited classification outputs and regions of interest, providing ultimate flexibility. It utilizes a powerful edge learning classifier tool that can identify and sort parts based on multiple features or characteristics, allowing for the classification of defects into different categories. Furthermore, it excels in optical character recognition, easily reading characters on reflective, low-contrast, and non-flat surfaces using AI-based recognition with minimal training.

The In-Sight 2800 vision system boasts a comprehensive toolset for tasks of varying complexity. It integrates both AI and rules-based tools within a single system, making it suitable for error-proofing applications of all kinds. Its user-friendly EasyBuilder development environment ensures rapid setup without the need for programming experience. Additionally, the In-Sight 2800 offers powerful imaging technology with High Dynamic Range (HDR) capabilities, enhancing accuracy in inspections and defect detection. Its modular and scalable architecture allows for quick adaptation to changing application settings and custom requirements, making it a versatile choice for manufacturers of all sizes.

What applications is In-Sight 2800 product best for?

- Electronics Manufacturing: The In-Sight 2800 is ideal for electronics inspection, ensuring the quality of printed circuit boards (PCBs), identifying defects, and verifying components with precision.

- Food Packaging: In the food industry, it offers quality control by inspecting labels, barcodes, and packaging for accuracy, ensuring compliance with food safety regulations.

- Pharmaceutical Production: It can be used to verify labels on pharmaceutical products, ensuring correct dosage information and expiration dates, enhancing product safety and compliance.

- Automotive Assembly: The system assists in automating the assembly line by inspecting and sorting components, enhancing production efficiency and reducing errors in the automotive manufacturing process.

- Medical Device Manufacturing: In the medical field, it verifies the accuracy of labels, ensuring traceability, and confirms the presence of critical components in medical devices for quality assurance.

What are the specifications of In-Sight 2800?

| Frame rate | 45 FPS |

| Image Type |

|

In-Sight Series Reviews

WRITE A REVIEW!In-Sight Series Use-Cases

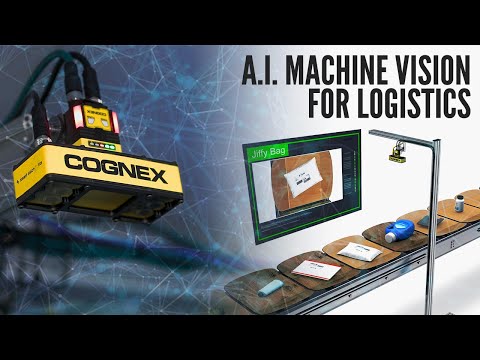

Streamlining Logistics Operations with In-Sight 2800 Detector by Cognex

The In-Sight 2800 Detector, a cutting-edge solution by Cognex, leverages innovative edge learning technology, on-board processing, and integrated lighting to enhance operational intelligence, increase inspection accuracy, and pinpoint process issues within logistics facilities of all sizes. This fully integrated sensor offers a user-friendly, rapid-deployment solution for item detection and classification in high-throughput environments.

Learn more