COGNEX In-Sight 3800 Pricing & Product Details

Ranked Nr. 256 of 126 2D Vision Systems

In-Sight 3800 Pricing

Choose your model

In-Sight 3800 Overview

What is In-Sight 3800?

The COGNEX In-Sight 3800 is an advanced vision system designed to address a wide range of manufacturing applications. It offers high-speed processing, high-resolution imaging, and remarkable flexibility. With twice the processing power of previous systems, it accommodates fast-paced production lines and optimizes throughput. This capability is essential for industries where maximizing efficiency is critical.

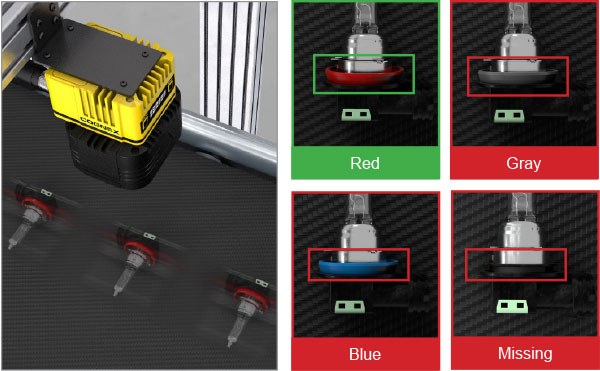

One of its standout features is the innovative edge learning technology embedded in the system. It allows both beginners and experts to deploy automation quickly through simple, example-based training. The pre-trained algorithms in edge learning tools handle a variety of classification and text reading tasks, from presence/absence detection to advanced optical character reading, improving the versatility of the system.

In addition to edge learning, the In-Sight 3800 also offers a comprehensive set of rule-based tools for more advanced applications. This combination of traditional rule-based vision and AI technology ensures that it can address a wide range of inspection and quality control tasks. Its flexible development options, including EasyBuilder and spreadsheet interfaces, cater to different user needs and job complexities. Additionally, the system's modular hardware allows for easy adaptation to changing requirements, making it suitable for evolving manufacturing demands.

What applications is In-Sight 3800 product best for?

- Automotive Quality Control: The COGNEX In-Sight 3800 is ideal for automotive manufacturing, where it can perform high-precision inspections on critical components such as engine parts, transmissions, and electronic assemblies. Its ability to detect even the subtlest defects and ensure accurate assembly verification makes it a valuable tool in maintaining the quality standards of the automotive industry.

- Electronics and Semiconductor Manufacturing: In the electronics and semiconductor industry, where tiny components and intricate circuitry are common, the In-Sight 3800 excels at tasks like reading codes, inspecting PCBs (printed circuit boards), and verifying electronic components' placement and orientation. Its high-resolution imaging capabilities and flexible development options are well-suited for these precise applications.

- Pharmaceutical and Medical Device Production: Ensuring the quality and correctness of pharmaceutical products and medical devices is of utmost importance. The In-Sight 3800 can handle complex inspection tasks, including reading labels, verifying packaging, and inspecting the integrity of medical components, helping manufacturers maintain compliance and product safety in these highly regulated industries.

- Food and Beverage Packaging: The system's ability to capture high-resolution images under various environmental conditions, such as different lighting setups, makes it a valuable asset in the food and beverage industry. It can inspect labels, barcodes, and packaging quality, ensuring that products meet branding and safety standards before reaching consumers.

- Consumer Electronics Assembly: In the assembly of consumer electronics like smartphones, tablets, and laptops, the In-Sight 3800's speed, accuracy, and flexibility shine. It can verify proper component placement, ensure connectors are correctly aligned, and read serial numbers and labels on finished products, contributing to efficient and reliable assembly processes.

- Textile and Fabric Inspection: In textile manufacturing, the system's image formation capabilities are well-suited for inspecting fabrics and textiles for defects, ensuring consistent quality in textile products such as apparel, upholstery, and technical textiles.

- Aerospace Component Inspection: The In-Sight 3800 is valuable for aerospace applications, where it can inspect critical components like turbine blades, avionics, and aerospace materials. Its high-resolution imaging and precise defect detection capabilities are crucial for maintaining the safety and performance of aerospace equipment.

What are the specifications of In-Sight 3800?

| Frame rate | 125 FPS |

| Image Type |

|

In-Sight Series Reviews

WRITE A REVIEW!In-Sight Series Use-Cases

AI and Rule-based Machine Vision System for Manufacturing – In-Sight 3800 Vision System | Cognex

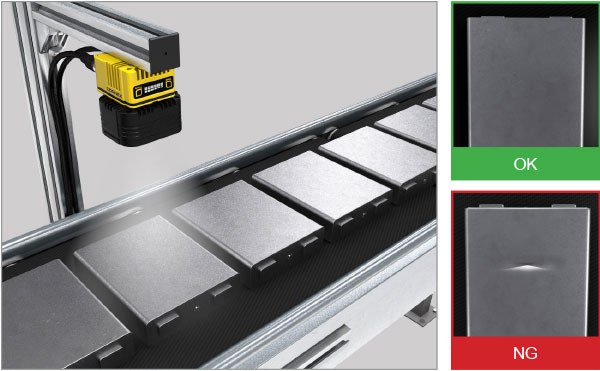

The In-Sight 3800 vision system by Cognex is an advanced solution designed for automated inspections in manufacturing. It is equipped with AI- and rule-based tools to address various manufacturing applications, such as defect detection, assembly verification, and character reading, with the added advantage of significantly increased processing speeds compared to its predecessors.

Learn more