COMAU Roboshop Next Gen Pricing & Product Details

Ranked Nr. 1 of 85 Robot Software

Roboshop Next Gen Overview

What is Roboshop Next Gen?

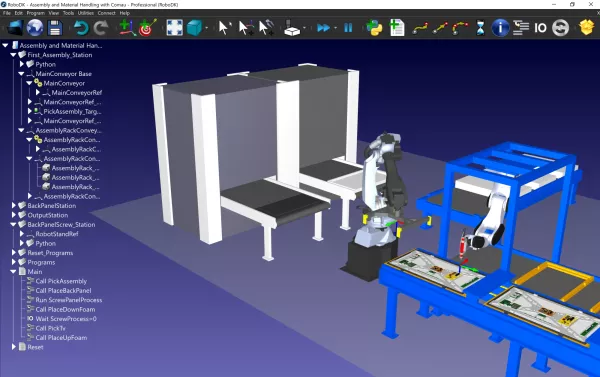

Roboshop Next Gen by Comau offers a modern PC platform designed to enhance interaction with Comau robot controllers through efficient simulation capabilities and direct communication. It integrates with RoboDK software, a leader in robotic simulation and offline programming, enabling advanced cell simulation. This allows users to preview and edit robot movements and logic through an improved graphical user interface, ensuring that program logic and movement sequences are optimally aligned before implementation.

This next-generation interface provides a highly intuitive user experience designed for both novice and experienced programmers. It supports a self-guided programming approach that reduces syntax errors and includes features like advanced autocomplete and editing tools. The system offers a real-time 3D trajectory visualization, which aids in programming accuracy and efficiency. Additionally, it facilitates quick navigation through all controller content and simplified program abstraction, helping users manage complex tasks with ease.

Roboshop Next Gen is tailored for a broad range of applications in automated manufacturing environments where precision and adaptability are paramount. Its capability to synchronize simulations with actual robotic operations makes it invaluable for developing and testing robot programs without interrupting production. The integration with RoboDK not only extends its utility in offline programming but also enhances its simulation features, making it a comprehensive solution for industries aiming to optimize robotic workflows and improve operational outcomes.

What applications is Roboshop Next Gen product best for?

- Automotive Manufacturing: Roboshop Next Gen is adept at supporting automotive production lines, where precision and efficiency are crucial. The platform's advanced simulation and offline programming capabilities allow for meticulous planning and execution of robot tasks, reducing downtime and enhancing production of complex automotive components.

- Electronics Assembly: In electronics manufacturing, where assembly processes require high accuracy and repeatability, Roboshop Next Gen facilitates precise robot programming and simulation. This ensures flawless execution of tasks such as circuit board assembly and placement of delicate components, minimizing the risk of errors.

- Heavy Machinery Production: For heavy industry, Roboshop Next Gen provides robust support in fabricating large and complex machinery parts. Its ability to simulate and visualize the entire production process in a 3D environment helps manufacturers to optimize the setup and operation of robots used in tasks such as welding and material handling.

What are the specifications of Roboshop Next Gen?

| Software type |

|