COMAU Roboshop Next Gen Alternatives & Competitors

Ranked Nr. 1 of 85 Robot Software

Top 10 Roboshop Next Gen Alternatives

- FANUC ROBOGUIDE

- Cyberbotics Ltd. Webots

- Tesseract Solutions KMeleon Software

- fruitcore robotics horstFX

- OCTOPUZ Robot programming and simulation software

- ABB Wizard Easy Programming

- COGNEX VisionPro Deep Learning

- ABB Arc Welding

- COGNEX VisionPro Software

- SIEMENS PLM Robcad

- EZPhysics EZPhysics

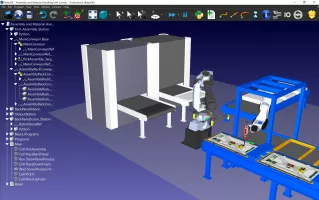

FANUC ROBOGUIDE

Offline programming | Simulation | Developer tools | Vision | WeldingFANUC ROBOGUIDE is a leading offline programming robot simulation software designed for FANUC robots. It offers process-focused robot simulation packages, enabling users to create, program, and simulate robotic workcells in a 3D virtual environment without the need for physical prototypes. This reduces costs and risks, allowing users to visualize single and multi-robot workcell layouts before actual installation.

ROBOGUIDE comes with various feature-specific modules. Handling Pro is ideal for material handling, packing, assembly, and material removal tasks, supporting line tracking and path programming. Paint Pro simplifies the painting process, allowing users to select paths and areas graphically for automatic program generation. Pallet Pro & Pallet tools enable users to build and test palletizing applications, offering a library of different pallet configurations. Weld Pro specializes in arc welding, featuring capabilities for CADD path programming.

In addition to the key features, ROBOGUIDE offers advanced functionalities like Auto Place, Duty, Cable, Vision, Spray, and COORD (coordination). These features enhance the software's versatility, enabling users to tackle complex and advanced systems efficiently. ROBOGUIDE supports CADD files, has built-in CADD models, and facilitates pre-programming, streamlining the setup and testing of sophisticated automation systems. Its compatibility with various software systems and extensive capabilities make it a unique and powerful option for industrial automation, providing valuable assistance to manufacturers and robotics developers.

Cyberbotics Ltd. Webots

SimulationWebots, developed by Cyberbotics Ltd., is an open-source, multi-platform simulation software tailored for robotics research, development, and education. It provides a comprehensive environment for modeling, programming, and simulating robots, offering tools that support a wide range of robotic systems. The software has been continuously maintained since 1998, ensuring robust functionality and compatibility with emerging technologies.

One of Webots' standout features is its extensive built-in library of pre-designed robots, sensors, and objects, which accelerates the simulation setup process. Additionally, its support for importing CAD models allows users to simulate custom robotic designs with high fidelity. Webots also features a web interface with streaming capabilities, enabling remote interaction and visualization of simulations in real time. Its automatic test suite for code ensures reliability and repeatability, making it suitable for professional and academic use.

Webots is widely used in various fields, including industry, research, and education, due to its flexibility and robust support ecosystem. Common applications include testing algorithms for autonomous navigation, robot design validation, and conducting online simulation challenges. With a large community and resources available, Webots is a key tool for fostering innovation and advancing robotic systems.

Tesseract Solutions KMeleon Software

Simulation- Set-up all of your line on a single software : robots, tools, controllers, sensors.

- Thanks to the technology FabrikCode, you'll be able to program without typing any line of code. Thanks to this technology based on "Drag & Drop" you'll gain more freedom.

- KMeleon gives you access to a universal language for the robotic programming of the main robot suppliers (Fanuc, ABB, Kuka, UR, Staubli…)

- Try your programs on KMeleon or on a robot, you'll choose ! Thanks to the 3D simulation interface you can simulate the different moves and measure your cycle time in no time.

fruitcore robotics horstFX

Offline programming | Simulation | Palletizing | Developer toolsThe horstFX control system features an intuitive graphical user interface optimized for touchscreens, enabling users to create and manage robotic programs graphically without programming skills. This design simplifies the process of developing both simple and complex applications, facilitating quick setup and operation.

The software comes in various packages tailored to specific needs. The horstFX Basic package supports text-based programming, digital I/O, process data recording, and IIoT integration. The horstFX Graphic package enhances functionality with graphical program creation, 3D object handling, and palletizing program generation. The horstFX External package provides advanced communication options, including XML-RPC, Modbus, and Profinet interfaces. The horstFX Performance package maximizes robot speed and load adjustment for improved cycle times.

Designed for flexibility, horstFX offers customizable software packages that can be booked monthly, ensuring users get the features they need for their particular applications. This approach also supports ongoing adjustments and upgrades to fit evolving requirements.

OCTOPUZ Robot programming and simulation software

Offline programming | SimulationChange the way industrial robots work for you

OCTOPUZ Offline Robot Programming (OLRP) software enables complex robot applications to be programmed in a virtual, offline environment, without disruption to your manufacturing process and without the need for an onsite robot programming expert. OCTOPUZ eliminates the need for your robots to be taken out of production, greatly improving your productivity and bottom line.

Build

Jump right into your next project with a personalized digital twin template of your robot cell.

Quickly setup your project environment using your cell template containing all of your fixed components.

Import your exact CAD part directly into your environment and easily position it exactly where you need it.

Program

Efficiently program your part with integrated tools for creating and optimizing robot motions.

Program multiple robots simultaneously, with support for many different robot brands in unique configurations. Regardless of robot brand, the programming process is identical.

Reduce your programming time with simple, effective tools which put your robot exactly where you need it.

Get your programs ready for production by identifying and solving your robot errors automatically.

Simulate

Validate the accuracy of your welding program through simulation in your digital twin.

Choose how you want see your project in action - by simulating start-to-finish, or by scrubbing to any location in your programs.

Optimize your project by calculating cycle time instantly.

Code

Create accurate robot code ready for immediate production.

Quickly generate your ready-to-run robot code in your robot brand's unique language.

View and update your robot code directly in OCTOPUZ; no need for a separate text editor.

ABB Wizard Easy Programming

Offline programming | Simulation | Palletizing | Developer toolsWizard Easy Programming by ABB is a no-code, graphical tool designed for the efficient programming of collaborative and industrial robots. It employs a block-based interface that enables users, regardless of prior experience, to drag, drop, and execute robot commands quickly. This system simplifies robot programming to basic movements, signals, and messages, while offering a "Skill Creator" feature for experts to design custom blocks tailored to specialized tasks. The program is pre-installed on ABB OmniCore™ controllers and is also accessible through RobotStudio® for free.

The platform supports a wide range of applications, making it versatile for industries requiring rapid deployment and flexibility in automation. Its integration with ABB’s broader robotics software ecosystem ensures compatibility and enhanced usability. Additionally, Wizard Easy Programming supports multiple languages, making it accessible globally, and utilizes ABB's RAPID programming language as the backbone for block-based commands.

A standout feature of the software is its intuitive navigation and user-friendly interface, which reduces setup time to under 10 minutes. For advanced users, the Skill Creator provides options to connect custom blocks to web apps, offering scalability for complex automation tasks. The system supports all collaborative and industrial robots powered by OmniCore™ controllers, ensuring a broad scope of applicability in automation workflows.

COGNEX VisionPro Deep Learning

Offline programming | Simulation | Monitoring | Bin picking | Calibration | Developer tools | VisionVisionPro Deep Learning is an AI-driven image analysis software tailored for intricate applications, automating tasks beyond the capabilities of rule-based algorithms. It excels in applications such as defect detection, assembly verification, part location, material classification, and character reading. It stands out by tolerating natural variation and discerning acceptable anomalies, simplifying the development of highly variable applications.

The software offers innovative features like the label checker, streamlining the image labeling process by identifying unmarked or mislabeled defects, significantly reducing manual labeling efforts. Parameter autotune expedites model calibration with a single click, ensuring both speed and accuracy in application setup. Fast line duplication accelerates the validation and deployment of deep learning models across multiple production lines, facilitating scalability and growth.

VisionPro Deep Learning provides an intuitive graphical training interface, simplifying the collection of images, neural network training, and testing on various image sets. Tool-chaining allows problem breakdown into smaller steps, enhancing optimization and requiring fewer training images. It offers flexibility in development, from machine integration to application-specific HMI, and integrates seamlessly with existing software and vision products, reducing engineering costs and enabling quick deployment in mass production environments.

ABB Arc Welding

Offline programming | Simulation | Monitoring | WeldingABB’s Arc Welding software suite is a powerful set of tools designed to streamline and enhance robotic arc welding processes. Central to the offering is RobotStudio ArcWelding PowerPac, a CAD-based offline programming tool that simplifies program creation by allowing users to define weld locations on a 3D model. The system automatically generates robot paths, including approach and departure points, significantly reducing setup time and increasing precision. This feature ensures efficient programming for complex geometries, helping manufacturers achieve faster deployment and improved consistency in welding quality.

Another standout component is RobotWare Arc, which integrates robotic positioning with process control into a single, intuitive system. This software supports advanced functionalities like seam tracking, fine adjustment during execution, and automatic re-strike after errors, ensuring high reliability in dynamic production environments. It also adapts to various welding equipment and incorporates features such as weaving, wire burnback, and rollback for optimal weld quality. These capabilities cater to industries requiring robust error handling and precise control in high-volume welding applications.

Lastly, the VirtualArc® tool provides offline simulation for MIG/MAG welding. It enables users to predict and tune welding parameters, optimizing weld quality and minimizing start-up times. VirtualArc® includes financial modeling tools, allowing manufacturers to estimate welding costs per meter and analyze productivity improvements. This focus on pre-planning and optimization makes ABB’s Arc Welding software indispensable for achieving cost-effective, high-quality welding processes in automotive, aerospace, and general industrial manufacturing.

COGNEX VisionPro Software

Offline programming | Monitoring | Calibration | Developer tools | VisionVisionPro is a leading PC-based vision software designed for versatile vision applications, compatible with various cameras and frame grabbers. It offers a comprehensive set of vision tools, including pattern matching, blob analysis, caliper measurements, image filtering, OCR, OCV, AI-based vision tools, and barcode reading. This software suits a wide range of applications, from inspection to identification, measurement, and robotic guidance, with seamless integration into .NET C# and C++ environments.

VisionPro provides a flexible development environment with modular tool blocks, enabling a balance between advanced programming and drag-and-drop application development. Users can dynamically configure software fixtures, employ reusable tool groups, and define custom tools, streamlining development and reducing cycle time. Whether you prefer drag-and-drop, scripting, or programming, VisionPro caters to different development approaches.

Moreover, VisionPro boasts universal communications and image acquisition compatibility with a broad spectrum of cameras, covering diverse acquisition requirements in factory automation. Its support for various camera types, formats, and industrial cameras ensures adaptability and convenience in implementing vision solutions across industries.

SIEMENS PLM Robcad

Offline programming | SimulationTecnomatix® Robcad software enables the design, simulation, optimization, analysis and offline programming of multi-device robotic and automated manufacturing processes in the context of product and production resources. It provides a concurrent engineering platform to optimize processes and calculate cycle times. With Robcad, you can design life-like, full-action mockups of complete manufacturing cells and systems. Robcad enables manufacturers to flawlessly introduce automated processes by allowing manufacturing engineers to virtually validate automation concepts upfront.

Benefits:

• Increase manufacturing quality,

accuracy and profitability

• Reduce labor hours and process

engineering lead time

• Enable better use of production

equipment

• Reduce production costs

• Shorten production ramp-up time

through validated processes

Features:

• Interoperability with major MCAD

systems

• Extensive robot libraries

• Component and complex kinematics

modeling

• 3D workcell layout definition

• Robotic path definition with reachability check, collision detection and

cycle time optimization

• Motion simulation and synchronization of multiple robots and devices

• Download/upload optimized

programs to/from the shop floor