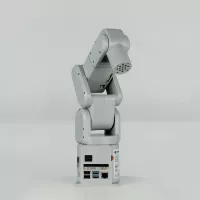

Elephant Robotics myPalletizer 260-M5 Specifications

Ranked Nr. 36 of 207 Cobots

Elephant Robotics myPalletizer 260-M5 is notable for its compact size and advanced technology. It features what Elephant Robotics calls "The Most Compact 4-axis Robotic Arm (Dual Screen Version) powered by M5Stack."

The M5Stack is a small, modular, and stackable development kit that provides a simple and efficient way to prototype and develop embedded systems. The myPalletizer 260-M5 is powered by an M5Stack core module, which helps to reduce the overall size of the robot while still providing powerful computing capabilities. The dual screen version of the myPalletizer 260-M5 has two M5Stack core modules, one for the robot arm control and one for the vision system.

Despite its small size, the myPalletizer 260-M5 is a highly capable robot that can handle payloads up to 5kg and has a maximum reach of 2600mm. It uses advanced sensors and algorithms to detect and locate products and pallets, and can be programmed to perform a wide range of palletizing patterns and configurations.

The myPalletizer 260-M5 also features advanced safety features, such as a safety scanner and a torque sensor, to ensure the safety of operators and surrounding personnel. The robot can be programmed to stop or slow down its movements when it detects any obstacles or abnormal conditions in its operating environment.

| Application |

|

| Industry |

|

| Payload | 0.25 kg |

| Reach | 260 mm |

| Repeatability | 0.3 mm |

| Number of Axes | 4 |

| Robot mass | 0.96 kg |