Framos Industrial Depth Camera D435e Starter Kit Specifications

Ranked Nr. 24 of 97 3D Vision Systems

The starter kit of the D435e includes the camera itself, a M12 to RJ45 ethernet cable and a M8 power cable with wall plug. It comes fully equipped to start and test the camera quickly.

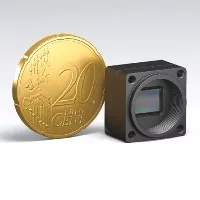

The FRAMOS Industrial Depth Camera D435e is built with Intel® RealSense™ technology. The depth camera has industrial M12 ethernet and M8 power connectors and features a wide field of view for depth and RGB sensors. Its water- and dust resistant housing is optimized for industrial environments. The FRAMOS Industrial Depth Camera D435e is ideal for OEMs and integrators who need 3D as well as 2D vision in their products and applications. The global shutter of the depth sensors allows for applications with fast motion, while the D415e provides higher accuracy through a higher baseline with rolling shutter sensors. The FRAMOS Industrial Depth Camera D435e is compatible with the Cross-platform SDK for Intel® RealSense™ devices, enabling multiple programming languages, wrappers, sample code and tools.

| Working distance | 200-10 mm |

| Scanning range (mm) | -10 mm |

| Scanning Range | m |

| Protection (IP) | 66 |

| Extra info | Applicability in Industrial Environments / Plug-and-play exchange with Intel® cameras / Plug-and-play with any GigE Vision compliant software / Locked connections with industrial grade M12 ethernet / Long cable length up to 100 m / Industrial grade IP66 rating (water and dust-proof) |