fruitcore robotics horstFX Specifications

Ranked Nr. 85 of 85 Robot Software

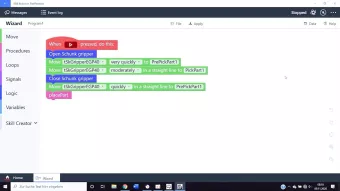

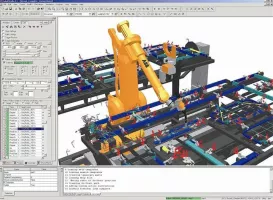

The horstFX control system features an intuitive graphical user interface optimized for touchscreens, enabling users to create and manage robotic programs graphically without programming skills. This design simplifies the process of developing both simple and complex applications, facilitating quick setup and operation.

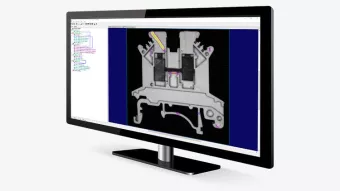

The software comes in various packages tailored to specific needs. The horstFX Basic package supports text-based programming, digital I/O, process data recording, and IIoT integration. The horstFX Graphic package enhances functionality with graphical program creation, 3D object handling, and palletizing program generation. The horstFX External package provides advanced communication options, including XML-RPC, Modbus, and Profinet interfaces. The horstFX Performance package maximizes robot speed and load adjustment for improved cycle times.

Designed for flexibility, horstFX offers customizable software packages that can be booked monthly, ensuring users get the features they need for their particular applications. This approach also supports ongoing adjustments and upgrades to fit evolving requirements.

| Software type |

|