Hikrobot Vision Master Specifications

Ranked Nr. 58 of 85 Robot Software

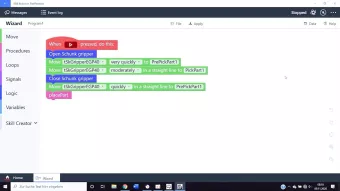

Hikrobot Vision Master (VM) offers versatile machine vision capabilities tailored for various industrial applications. It features over 1000 image processing operators and supports multiple development modes, including a graphical interface for intuitive setup, an SDK for customized development, and an operator design mode for integrating visual tools into user-defined processes. This flexibility allows users to quickly build and adapt vision applications.

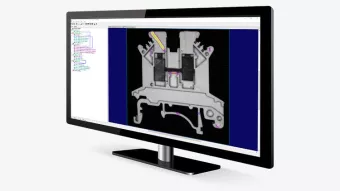

The VM excels in precision positioning, measurement, identification, and defect detection. It uses high-performance deep learning algorithms to accurately identify and classify defects on workpieces, including scratches and shape inconsistencies, overcoming issues like surface texture and noise. The software also supports high-speed OCR and barcode reading for complex backgrounds and varying image conditions.

With its graphical user interface and robust external resource management, VM simplifies interaction through drag-and-drop operations and integrates with various industrial cameras and devices. It offers seamless control of external equipment, enhancing its adaptability and efficiency in different machine vision tasks.

| Software type |

|