ibk IngenieurConsult CobotPalletizer Specifications

Ranked Nr. 11 of 61 Turnkey Robot Solutions

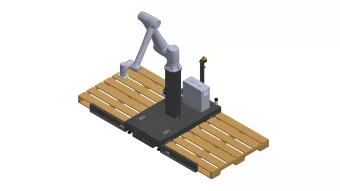

The ibk CobotPalletizer is a turnkey palletizing solution based on a Cobot KR1410 from Kassow Robots. The CobotPalletizer is designed to require a minimum footprint and is a powerful solution for palletizing two pallets.

It can handle up to 3.5 packages/minute or 200 packages per hour. It has a maximum payload of 10 kg.

CobotPalletizer Downloads

FACTSHEET PALLETIZING KIT 07 22 DE 5

You need to

register

to download this file.