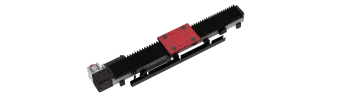

igus drylin® ZLW: Belt drive for extreme conditions Specifications

Ranked Nr. 40 of 33 Linear Motion Systems

The long standing toothed belt drives have been developed for the fast positioning of low loads. These linear units with toothed belt drive are corrosion resistant, light and compact, besides having a low mass inertia due to low deadweight of guide and sliding carriage.

New this year:

Version LT for cold storage down to -30°C

Version UW for under water use

Features:

100 % lubricant-free version with plain bearings

Many-sided and simple assembly

Freely selectable stroke length

Low height and solid

Light and corrosion resistant

| Max. Stroke | 1000-2000 mm |

| Type |

|