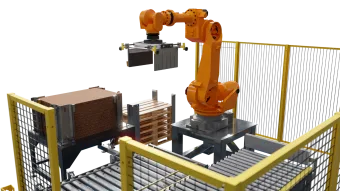

Kogena Robots Diagnostics Platform Specifications

Ranked Nr. 68 of 85 Robot Software

Complete cloud platform for robots and cobots to optimize production and minimize downtimes.

Real – time robot overview

With live data compare actual performance, analyze historical data to recognize and predict future failure events and compare different robots simultaneously.

User friendly interface

Perfect overview of all robots in your network - easy access to analyze workflows, aggregates on data, filtering and data comparison entries.

Advanced diagnostic tools

Machine maintenance involves regularly checks during production. Diagnostic tool enables to implement preventive maintenance at different workstations.

Production monitoring

Production monitoring from start to end - to understand output consistency, calculate throughputs with our unique dashboards.

Historical data

Data is accessible all the time, from anywhere and with no additional limitations.

Real time alerts and notifications

Important alerts, warnings and notifications via e-mail and SMS to know immediately about critical situations.

Counters and aggregated on data

Collected valuable insights from equipment and complete visibility into the full production process. In addition, efficient overview of what is causing production downtime.

Access to KPIs

KPIs on cycle time, shifts, bottlenecks, downtime and overall efficiency. Dashboards are customized by thinking of daily production shifts scenarios.

Remote data collection

Remote access to data with use of GSM connectivity or WAN/LAN network.

Daily automated reports

PDF reports with essential business information on output - flow tracking, Robots performance, planned versus actual production, manufacturing quality, OEE and much more. Summary e-mail every morning!

| Software type |

|