Liberty Reach VFix Specifications

Ranked Nr. 124 of 97 3D Vision Systems

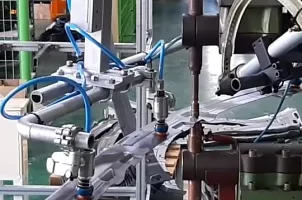

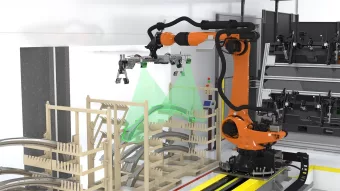

The Liberty Reach VFix is an advanced solution for 3D vision robot guidance on large parts or vehicle bodies. Utilizing stationary mounted sensors, it efficiently measures six degrees of freedom offsets with exceptional speed, providing millisecond response for 6D offset calculations. Notably, VFix is robust, built to withstand harsh factory conditions, and is unaffected by ambient lighting, reducing faults and downtime. It offers versatile capabilities, accurately calculating significant part-to-part shifts and rotations, and can seamlessly accommodate model changes and style additions.

Designed for manufacturing processes, VFix quickly scans entire objects in one action, capturing vital data for guiding robots in tasks such as part handling, coating application, and surface sealing. Its ability to perform complex calculations swiftly and dependably makes it stand out among guidance systems. Installation, operation, adjustments, and maintenance are streamlined and cost-effective, making the Liberty Reach VFix a powerful solution for 3D vision-guided robot applications in industries like automotive and manufacturing.

| Industry |

|

| Application |

|

| Image Type |

|