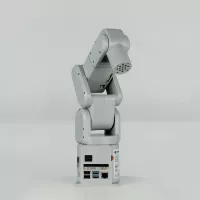

Lynxmotion AL5D Specifications

Ranked Nr. 81 of 207 Cobots

The AL5D robotic arm delivers fast, accurate, and repeatable movement. The robot features: base rotation, single plane shoulder, elbow, wrist motion, a functional gripper, and optional wrist rotate. The AL5D robotic arm is an affordable system with a time tested rock solid design that will last and last. Everything needed to assemble and operate the robot is included in the kit, with several different software control options.

Note that we have tested the arm to hold at most <10oz at full reach without any additional products such as the wrist rotate upgrade installed on the arm (which decreases the payload). The lift capacity increases as the load is closer to the base, but depends on the configuration of the arm.

The Mechanics

The aluminum robotic arm is made from our Servo Erector Set components for the ultimate in flexibility and expandability. The kit consists of black anodized aluminum brackets, Aluminum tubing and hubs, custom injection molded components, and precision laser-cut Lexan components. The arm uses 1 x HS-485HB in the base, 1 x HS-805BB in the shoulder, 1 x HS-755HB in the elbow, 1 x HS-645MG in the wrist, and 1 x HS-422 in the gripper.

Arm Control Options

We now have arm control options. They each have their own unique operating methodology and feature sets.

- FlowBotics Studio is an easy to use graphical program which allows you to easily get your AL5 robot up and running without the need to create code. Use the software to manipulate the real arm using the virtual arm, and create, record and play back your own sequences. Software allows for wrist rotation and additional servos.

- FlowArm PLTW provides a graphical interface for controlling the AL5A, AL5 and AL5D arms. You can also create and save sequences. It is a stand-alone .exe program which was created using FlowBotics Studio.

- SSC-32 Servo Sequencer Utility: a free interface which gives you control over each servo and allows you to create sequences.

- Alternately the servo motors can be controlled directly from a microcontroller. We sell the arm without electronics for this purpose.

| Industry |

|