Micropsi Industries MIRAI AI Vision System Pricing & Product Details

Ranked Nr. 250 of 126 2D Vision Systems

MIRAI AI Vision System Overview

What is MIRAI AI Vision System?

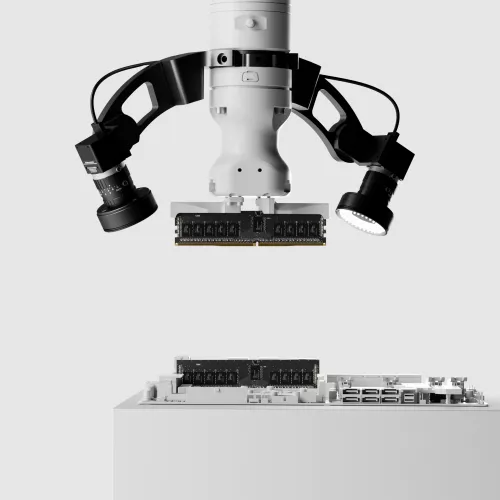

MICROPSI INDUSTRIES’ AI-based vision system, MIRAI, makes it possible to automate tasks otherwise considered too complex to automate. Thanks to MIRAI, robots learn how to robustly react to unpredictable factory conditions, handling variance in position, shape, color, lighting, and background.

MIRAI generates real-time robot movements and consequently offers higher reliability and precision than traditional measure-and-execute vision systems. No calibration and measurement are required (no CAD files required). Not only that, MIRAI is more flexible than traditional solutions. MIRAI-guided robots can be trained and retrained for various tasks.

Benefits of MIRAI:

01 – Automation Independence: Solve automation problems on your own. Little integration is needed. No knowledge of AI is required.

02 – Competitive Edge: Bring state-of-the-art AI technology into your factory.

03 – Increase Productivity: Boost productivity and gain business resilience by finally automating tasks previously considered too complex.

04 – Application Flexibility: MIRAI-equipped robots can be trained and retrained for various tasks.

05 – Customized Support: Our engineers can help you deploy an automation solution and keep it live.

What applications is MIRAI AI Vision System product best for?

01 – End-of-Line Testing

02 – Assembly

03 – Handling

04 – Screwdriving

05 – Rack Hanging

06 – Insertion

07 – Your specific application

What are the specifications of MIRAI AI Vision System?

MIRAI AI Vision System Reviews

WRITE A REVIEW!MIRAI AI Vision System Use-Cases

BSH Automates Leak Testing with MIRAI

BSH implements the MIRAI robot controller to automate leak testing in their refrigerator production process. The robotic solution efficiently identifies and inspects solder joints with precision, overcoming variations in position, color, and shape of each refrigerator. The fully automated process ensures high-quality outcomes and reliable performance while reducing operating costs and maintenance for BSH. No programming or AI is required for robot training, making the implementation seamless and effective.

Learn moreSiemens Energy Uses MIRAI to Refurbish Gas Turbines Blades

Siemens Energy utilizes the MIRAI system to automate the refurbishment of gas turbine vanes. The industrial robot, equipped with MIRAI, efficiently inserts dispensing needles into the drillings of the vanes, overcoming variations in position, shape, and condition. The automated process ensures improved accuracy, enhanced efficiency, and adaptability to different vane sizes and wear conditions, resulting in time and labor cost savings for Siemens Energy.

Learn more