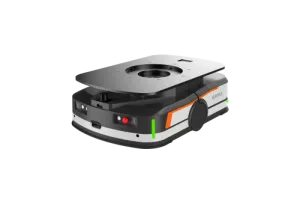

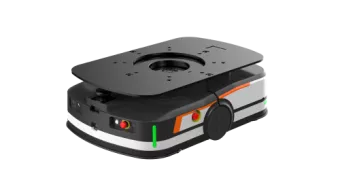

Nord Modules PL-EU-MiR Specifications

Ranked Nr. 207 of 183 Mobile Robots

The PL-EU-MiR Pallet Lift from Nord Modules is an advanced top module designed to optimize internal logistics by automating the transportation of pallets within a facility. This module is compatible with several Mobile Industrial Robots (MiR) models, including the MiR500, MiR600, MiR1000, and MiR1350. It can lift and transport EU size pallets with dimensions of 1200 x 800 mm and a maximum payload of 1250 kg. The PL-EU-MiR can lift pallets autonomously from a pallet rack, providing stable handling and transportation.

A standout feature of the PL-EU-MiR is its robust design and durability. It utilizes an industrial actuator with a ball screw spindle, a servo motor, and a dynamic brake, complemented by a scissor lift design with cam followers. This configuration allows it to handle uneven loads of up to 850 kg in one corner. The module is built for longevity, with a minimum life expectancy of 600,000 lift cycles at maximum payload. Its bearings in all moving joints and straightforward mounting process ensure ease of use and maintenance.

In terms of communication and power, the PL-EU-MiR interfaces via Modbus and is equipped with a stack light for process status, service needs, and error feedback. It operates on 48V safe power for the drive and 24V for the controller. Additionally, the module can collect and send essential data, such as total lift counts and error codes, to the MiR AMR for monitoring and analysis. This capability enhances operational efficiency and ensures seamless integration into automated logistics workflows.

| Navigation System |

|

| Control Interface |

|

| Payload | 1250 kg |

| Application |

|

| Industry |

|

| Product mass | 85 kg |

| Type of Technology |

|