Oqton Robotic Welding Software Alternatives & Competitors

Ranked Nr. 69 of 85 Robot Software

Top 10 Robotic Welding Software Alternatives

- ABB RobotStudio®

- ABB IRC5

- Smooth Robotics SmoothTool

- Wandelbots WELDING

- Oqton 3D Inspection Software

- ABB Arc Welding

- Wandelbots Teaching

ABB RobotStudio®

Offline programming | Simulation | Developer tools | VisionABB's RobotStudio stands out as a powerful simulation and offline programming software, widely regarded as the most used tool of its kind in the world. Its offline programming capability enables programming, training, and optimization of robot systems without disrupting production, ensuring maximum return on investment and minimizing production downtime.

Built on the ABB Virtual Controller, RobotStudio offers realistic simulations using actual robot programs and configuration files from the shop floor. Its feature-rich package includes Virtual Meetings, enabling collaboration through sharing digital robot solutions in web meetings, reducing travel expenses and time. The Digital Twin concept allows real-time simulation of the production system without affecting ongoing production, facilitating changes and optimization in the virtual world.

RobotStudio's Virtual Commissioning replicates the production cell virtually, solving technical issues in advance and speeding up commissioning. The Stop Position Simulation visualizes optimal braking distance with millisecond precision, enhancing SafeMove usage, reducing cell footprint, and streamlining commissioning. Moreover, the Augmented Reality feature overlays modeled solutions as holograms in the real-life production environment, accessible through augmented reality glasses or smart devices. These unique specifications make ABB's RobotStudio an ideal option for industrial automation and offline programming.

ABB IRC5

Offline programming | Simulation | Developer tools | Vision | Scheduling | WeldingABB's IRC5 is an advanced robot controller, known as the benchmark in robot controller technology. It stands out with unique motion control capabilities, offering flexibility, safety, modularity, application interfaces, multi-robot control, and PC tool support. The IRC5 can be easily integrated into various robotic systems, and its variants provide cost-effective solutions for different industries like automotive and electronics.

Safety is a key feature of IRC5, equipped with built-in safety functions like safety-rated stop and emergency stop. Its modularity allows easy maintenance and system upgrades, while supporting multi-robot control for seamless collaboration. The controller offers various application interfaces, including fieldbus and Ethernet, facilitating integration into diverse applications like material handling and painting.

Compatible with ABB's RobotStudio and third-party software tools, the IRC5 simplifies programming and simulation for robotics applications, reducing development time and costs. With its wide range of features and capabilities, the IRC5 is a versatile, high-performance choice for industrial automation, especially in demanding and safety-critical environments.

Smooth Robotics SmoothTool

WeldingSmooth Robotics has released an updated version of its welding software, the SmoothTool, with significant enhancements. The offset function now allows users to easily copy and adjust offsets in multiple directions, offering more flexibility in welding tasks. New arc options enable precise control over weaving parameters, enhancing welding control and results.

Improved weaving transitions in the SmoothTool ensure smoother and more efficient transitions for higher-quality welds. The software also integrates seamlessly with various power sources, offering greater flexibility and efficiency in power source selection for welding tasks.

In addition to these major updates, minor improvements include 3D visualization for better path planning and stitch welding control. The user-friendly interface, quick installation, and minimal training requirements make the SmoothTool an ideal choice for a wide range of welding applications.

Wandelbots WELDING

WeldingWandelbots is a company that offers an intuitive welding app designed for welders to set up robotic automations quickly and easily. The app guides the user through the whole welding process, with no coding or robotic knowledge required. With the Wandelbots app, welders can impress their colleagues and supervisors by saving time and money while automating their production line.

For planners, Wandelbots offers flexibility to quickly reprogram robots for new work pieces. As everyone can work with the intuitive app, planners can plan personnel resources freely and without dependencies. This enables planners to improve their production planning and ensure that the company stays competitive and counteracts labor shortages.

By easily automating the production line with the Wandelbots app, businesses can ramp up their production and save what they would have spent on complex reprogramming and production downtime. This app can help businesses stay competitive and remain profitable in a challenging economic environment.

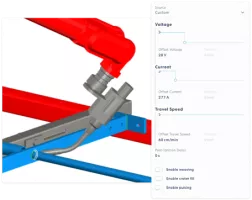

Wandelbots offers an easy-to-use welding software that works with MIG/MAG welding. With the Wandelbots welding software, users can generate paths that the robot will move to in three ways - via Cartesian control, TracePen, and soon CAD models. This software allows users to define the start and end points of a path with millimeter precision, making the welding process much simpler.

Users can edit and optimize the welding path in the Wandelbots app. This includes setting up commands that turn the welding torch on and off, or adjusting some welding parameters of the welding power source. The intuitive user interface makes it easy to understand and operate the software, making learning robot programming a breeze.

Using the Wandelbots welding app, different welds and weld parameters can be defined and tested with just a few clicks. Weld angles can be defined and easily transferred to other path points. Speeds can also be set up specifically and transferred to the respective workpiece, making the definition of welding seams lightning-fast.

Once the welding path has been recorded and edited, the user can export the robotic welding code to their welding robot and execute it immediately. The Wandelbots system already integrates various welding power sources and can control them via the app, making the whole process seamless and efficient.

In conclusion, the Wandelbots welding software is a game-changer in the welding industry. It is easy to use, saves time and money, and allows businesses to stay competitive and profitable. With its intuitive user interface, lightning-fast definition of welding seams, and flexibility, it is a must-have for any business looking to automate its welding production line.

Oqton 3D Inspection Software

Monitoring | Calibration | Developer toolsOqton's 3D Inspection Software offers an accessible solution for scan-based 3D inspection, making it easier for engineers and quality assurance managers across different industries to improve their manufacturing processes. By utilizing 3D scanning technologies to capture point-cloud data, the software allows for quick cataloguing and inspection of parts being manufactured, resulting in improved part quality, faster time-to-market, and significant cost savings through reduced scrap and enhanced process sustainability.

The software's unmatched accuracy, flexibility, and speed are its key features, making it an ideal tool for optimizing the quality process of production environments. Its user-friendly interface enables more people to access and use the technology, while its compatibility with different 3D scanning devices allows for greater flexibility in integration with existing systems. Additionally, the software's ability to quickly identify defects and deviations in parts being manufactured helps reduce errors and increases overall quality control.

Oqton's 3D Inspection Software is also designed to lower the barrier to entry for scan-based 3D inspection, making it accessible to more people in more production environments. This means that companies of all sizes can benefit from the technology, and it can be easily integrated into different manufacturing processes. Overall, Oqton's 3D Inspection Software provides an effective solution for improving quality control, reducing waste, and enhancing sustainability in manufacturing operations.

ABB Arc Welding

Offline programming | Simulation | Monitoring | WeldingABB’s Arc Welding software suite is a powerful set of tools designed to streamline and enhance robotic arc welding processes. Central to the offering is RobotStudio ArcWelding PowerPac, a CAD-based offline programming tool that simplifies program creation by allowing users to define weld locations on a 3D model. The system automatically generates robot paths, including approach and departure points, significantly reducing setup time and increasing precision. This feature ensures efficient programming for complex geometries, helping manufacturers achieve faster deployment and improved consistency in welding quality.

Another standout component is RobotWare Arc, which integrates robotic positioning with process control into a single, intuitive system. This software supports advanced functionalities like seam tracking, fine adjustment during execution, and automatic re-strike after errors, ensuring high reliability in dynamic production environments. It also adapts to various welding equipment and incorporates features such as weaving, wire burnback, and rollback for optimal weld quality. These capabilities cater to industries requiring robust error handling and precise control in high-volume welding applications.

Lastly, the VirtualArc® tool provides offline simulation for MIG/MAG welding. It enables users to predict and tune welding parameters, optimizing weld quality and minimizing start-up times. VirtualArc® includes financial modeling tools, allowing manufacturers to estimate welding costs per meter and analyze productivity improvements. This focus on pre-planning and optimization makes ABB’s Arc Welding software indispensable for achieving cost-effective, high-quality welding processes in automotive, aerospace, and general industrial manufacturing.

Wandelbots Teaching

Offline programming | Simulation | Monitoring | Calibration | Developer toolsWandelbots Teaching is an innovative product that enables skilled workers and application experts on the shop floor to teach robots with ease. It's a user-friendly end-to-end robot programming system that requires zero code, making it a highly intuitive tool to use. With this product, companies can automate more independently and reduce robot programming costs by up to 75%. Wandelbots Teaching empowers the workforce and minimizes downtimes in production, making it an ideal solution for automating small batches.

One of the most significant benefits of Wandelbots Teaching is the increased flexibility it provides on the production line. Traditionally, only a few expensive experts could program industrial robots, resulting in slow automation processes and increased total cost of ownership. With this product, even staff with no previous experience can teach a robot on the shop floor, reducing the need for external specialists and cutting programming costs significantly. The product is designed to be highly intuitive, with an easy-to-use interface that enables anyone to program a robot with minimal training.

For management, the benefits of Wandelbots Teaching are clear: reduced costs and increased automation independence. With the ability to program robots in-house, companies can automate more processes without relying on expensive external experts. The result is a more streamlined production process and a significant reduction in programming costs.

Skilled workers also benefit from Wandelbots Teaching. By providing an intuitive user interface without complex programming, even blue-collar workers and application experts can teach a robot. This way, production can grow despite the lack of skilled workers for monotonous tasks. The product's AI-based motion type sensing and intelligent overlays/blends allow adjustments of the recorded path within the app, making it easy to generate and edit even complex robot paths.

Finally, Wandelbots Teaching is an excellent solution for automating small batches. With no-code programming, robot processes can be taught and implemented quickly and flexibly, minimizing downtimes in production and enabling profitable automation of small batches. The product is compatible with various applications in production, including robotic welding, grinding, gluing, pick & place, and more. With Wandelbots Teaching, companies can take advantage of the latest technology to streamline their production processes and increase efficiency.