Photonfocus DR1-D1312-200-G2 Pricing & Product Details

Ranked Nr. 66 of 126 2D Vision Systems

DR1-D1312-200-G2 Pricing

Choose your model

DR1-D1312-200-G2 Overview

What is DR1-D1312-200-G2?

The Double Rate camera series DR1-D1312(IE)-200-G2 is based on the Photonfocus A1312 and A1312IE CMOS image sensors with LinLog® technology. The Double-Rate cameras are nearly 100% faster than standard GigE cameras and use only one data cable (no link-aggregation). The Photonfocus A1312 CMOS sensors with a full well capacity (FWC) of 90 ke- are optimized for high dynamic range applications and a high signal-to-noise ratio (SNR). The cameras have the GigE interface (GigEVision).

| Resolution | Frame rate [fps] |

| 1312 x 1082 | 135 |

| 1024 x 1024 | 180 |

| 800 x 600 | 385 |

| 640 x 480 | 585 |

| 544 x 512 | 636 |

Due to their excellent capabilities of managing high frame rates CMOS cameras are at the fore front of high speed image capturing and image analysis. Until recently CMOS high speed cameras were used as compact camera heads with an internal image buffer or as landed camera heads with a CameraLink full interface and frame grabbers with a large image buffer.

Applications such as motion analysis (e.g. in the area of bionic, sports or biomechanical analysis) and process failure analysis (e.g. burst or fracture of tools, failure of handling systems, breakdown of packaging systems) require frame rates which are increasingly being provided by fast CMOS standard cameras. These are also used in machine vision applications. The preferred camera choice for such applications are standard machine vision cameras with a GigE interface due to their flexibility in long transmission distance. For even faster motion analysis cameras with a double frame rate, being captured with a GigE interface and a combined link aggregation with recording systems are required.

Photonfocus has recognized the need and requirements of these applications. Their double rate (DR) camera technology displays a double bandwidth for data transmission via the standardized GigE Vision interface, common for machine vision applications. The technology is based on the standard software protocol GeniCam. This Photonfocus technology is based on standard bandwidth tools and standard software libraries used for high speed image capturing. Even a multiple camera system set-up can be easily implemented due to the usage of the GigE standard, in contrary to a point-to-point connection as used in Link aggregation solutions. With the GigE standard the data transmission is not getting interrupted.

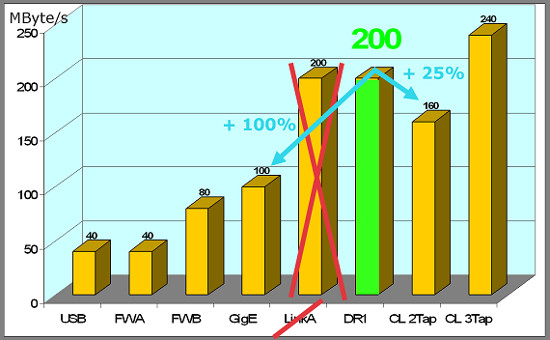

Comparison of data rates of different interfaces used in machine vision

For this applications Photonfocus has developed the Double Rate (DR) camera technology which is setup on the standard implementation of the GigE interface and standard software protocols as GigEVision and GenICam. In the result high speed applications could be realized with standard tools and libraries. The setup of multi camera systems is easy and is not disabled as with link aggregation.

The Double Rate technology overcome the draw backs of link aggregation and enables frame rates of 585fps @ VGA resolution and 204fps @ 960 x 960 pixel. The Double-Rate camera DR1-D1312-200-G2-8 is 25% faster than standard Cameralink Base cameras and 100% faster than standard GigE cameras.

FEATURES:

- Double Rate technology

- Configurable region of interest (ROI)

- Up to 512 regions of interest (MROI)

- Decimation in y-direction

- Image correction

- 2 look-up tables (12-to-8Bit) on user-defined image region (Region-LUT)

- Constant frame rate independent of exposure time

- Crosshairs overlay on the image

- 3x3 convolver for image preprocessing

- Temperature monitoring of sensor and camera

- Ultra low trigger delay and low trigger jitter

- Extended trigger input and strobe output functionality

What applications is DR1-D1312-200-G2 product best for?

Industrial Automation

Fully automated production, self-learning machines and robots: Many Industry 4.0 applications rely on machine vision and the depth of detail in image data. High-precision embedded vision systems are used in process and quality control, as well as for measuring object and surface characteristics. Photonfocus develops and produces both sensors for integration into existing systems and ready-to-use solutions with onboard decision-making.

Agriculture

Increasingly, the digitalized agriculture and forestry industry relies on visual systems. For example, the use of drones with hyperspectral cameras enables the detection of parasite infestation, plant diseases, or the assessment of the degree of maturity of the crop. Our sensors do what the human eye cannot see and assist the agriculture industry on the way to more efficient solutions that are future-proof.

Automotive

Numerous applications in the automotive industry rely on fully automatic inspection systems for checking production processes, object properties and quality. High-precision embedded vision systems perform 2D and 3D image acquisition simultaneously, thereby ensuring that industrial robots and production plants are as profitable and productive as possible.

Material Processing

Fully automated sorting processes save the use of humans for monotonous and tedious activities. Photonfocus sensors are highly reliable when it comes to deciding which foods can be resold or which are spoiled, or separating waste into glass, plastic, metal or other materials.

Traffic & Transport

Embedded vision applications count and identify vehicles in road traffic and thus influence traffic. In rail applications, precise measuring technology with machine vision inspects tracks and train components, detecting wear and defects. At the same time, intelligent onboard solutions give train drivers and maintenance staff direct feedback regarding the condition of the route, thereby ensuring safety and keeping downtimes to a minimum.

What are the specifications of DR1-D1312-200-G2?

| Image Type |

|