Photonfocus OEM-D1024E-160-LC Alternatives & Competitors

Ranked Nr. 66 of 126 2D Vision Systems

Top 10 OEM-D1024E-160-LC Alternatives

- Photonfocus OEM-D2080-160-LC

- Photonfocus MV2-D2448-S01-G1

- Photonfocus MV2-D2448-S01-G1

- Photonfocus DR0-D1920-S01-480-G2

- Lano Photonics Economical Line Scan Camera

- Lano Photonics LANO-AF500-24GC

- Lano Photonics LANO-AN230-40GC

- Alkeria CO4K-M

- Lano Photonics AN Series Medium & high-speed Area Scan Camera-60MM

- Alkeria CO12S-M

- Lano Photonics AN Series Medium & high-speed Area Scan Camera-AS

Photonfocus OEM-D2080-160-LC

Monochrome | Near-infraredFor customer that prefer to design their own camera solution but do not want to spend time on the sensor integration we offer a range of OEM camera modules. All of the features and technical data are identical to the standard cameras except for the interface board which is not included. Thus making it a perfect solution to interface to your own embedded vision system.

The module series OEM-D2080(IE)-160-LC is based on the Photonfocus A2080 and A2080IE CMOS image sensors. These Photonfocus CMOS sensors with a full well capacity (FWC) of 90 ke- are optimized for high dynamic range applications and a high signal-to-noise ratio (SNR). The modules have a parallel interface.

These modules focus on demanding applications in industrial image processing. They offer an extraordinary wide dynamic range due to the LinLog® technology and a high framerate combined with high resolution. Due to the global shutter, even high-speed applications with exposure times in the µs-area are possible.

FEATURES:

- Configurable region of interest (ROI)

- Up to 512 regions of interest (MROI)

- Decimation in y-direction

- Image correction

- 2 look-up tables (12-to-8Bit) on user-defined image region (Region-LUT)

- Constant frame rate independent of exposure time

- Crosshairs overlay on the image

- 3x3 convolver for image preProcessing

- Temperature monitoring of sensor and camera

- Camera informations readable over SDK

- Ultra low trigger delay and low trigger jitter

- Extended trigger input and strobe output functionality

- Status line in picture

Photonfocus MV2-D2448-S01-G1

MonochromeThe camera series MV2-D2448-S01-G1 is based on the SONY IMX250 CMOS image sensor. The IMX250 CMOS image sensor is optimized for low light conditions and is available as standard monochrome version. The camera has the GigE interface (GigEVision).

These cameras focus on demanding applications in industrial image processing. They are optimized for low light applications. Due to the global shutter, even high-speed applications with exposure times in the µs-area are possible.

FEATURES:

- Configurable region of interest (ROI)

- Up to 8 regions of interest (MROI)

- Decimation in y-direction

- 2 look-up tables (12-to-8Bit) on user-defined image region (Region-LUT)

- Constant frame rate independent of exposure time

- Crosshairs overlay on the image

- Temperature monitoring of camera

- Camera informations readable over SDK

- Ultra low trigger delay and low trigger jitter

- Extended trigger input and strobe output functionality

- Status line in picture

Photonfocus MV2-D2448-S01-G1

MonochromeThe camera series MV2-D2448-S01-G1 is based on the SONY IMX250 CMOS image sensor. The IMX250 CMOS image sensor is optimized for low light conditions and is available as standard monochrome version. The camera has the GigE interface (GigEVision).

These cameras focus on demanding applications in industrial image processing. They are optimized for low light applications. Due to the global shutter, even high-speed applications with exposure times in the µs-area are possible.

FEATURES:

- Configurable region of interest (ROI)

- Up to 8 regions of interest (MROI)

- Decimation in y-direction

- 2 look-up tables (12-to-8Bit) on user-defined image region (Region-LUT)

- Constant frame rate independent of exposure time

- Crosshairs overlay on the image

- Temperature monitoring of camera

- Camera informations readable over SDK

- Ultra low trigger delay and low trigger jitter

- Extended trigger input and strobe output functionality

- Status line in picture

Photonfocus DR0-D1920-S01-480-G2

MonochromeThe camera DR0-D1920-S01-480-G2 is based on the SONY IMX174 CMOS image sensor. The IMX174 CMOS image sensor is optimized for low light conditions and is available as standard monochrome version. The Double-Rate cameras are nearly 100% faster than standard GigE cameras and use only one data cable (no link-aggregation). The camera has the GigE interface (GigEVision).

| Resolution | Frame rate [fps] |

| 1920 x 1200 | 94 |

| 1920 x 1080 | 104 |

| 1024 x 1024 | 196 |

| 640 x 480 | 402 |

Due to their excellent capabilities of managing high frame rates CMOS cameras are at the fore front of high speed image capturing and image analysis. Until recently CMOS high speed cameras were used as compact camera heads with an internal image buffer or as landed camera heads with a CameraLink full interface and frame grabbers with a large image buffer.

Applications such as motion analysis (e.g. in the area of bionic, sports or biomechanical analysis) and process failure analysis (e.g. burst or fracture of tools, failure of handling systems, breakdown of packaging systems) require frame rates which are increasingly being provided by fast CMOS standard cameras. These are also used in machine vision applications. The preferred camera choice for such applications are standard machine vision cameras with a GigE interface due to their flexibility in long transmission distance. For even faster motion analysis cameras with a double frame rate, being captured with a GigE interface and a combined link aggregation with recording systems are required.

Photonfocus has recognized the need and requirements of these applications. Their double rate (DR) camera technology displays a double bandwidth for data transmission via the standardized GigE Vision interface, common for machine vision applications. The technology is based on the standard software protocol GeniCam. This Photonfocus technology is based on standard bandwidth tools and standard software libraries used for high speed image capturing. Even a multiple camera system set-up can be easily implemented due to the usage of the GigE standard, in contrary to a point-to-point connection as used in Link aggregation solutions. With the GigE standard the data transmission is not getting interrupted.

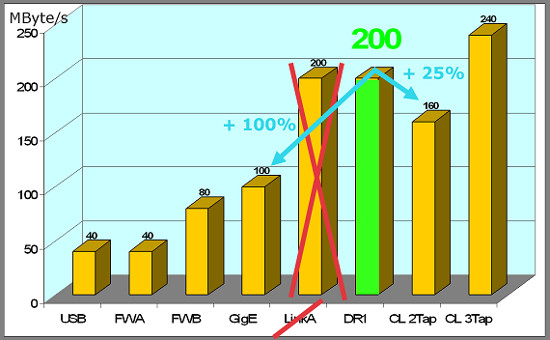

Comparison of data rates of different interfaces used in machine vision

This technology eliminates the complications of systems using cameras with link aggregation right from the beginning.

Once more Photonfocus demonstrates its industry leader position in the area of cutting edge high speed camera systems. The double rate (DR) camera technology is up to 25% faster than conventional CameraLink base cameras and even 100% faster than mainstream cameras with a standard GigE interface.

An additional advantage of the implemented modulation technology is the capability to save unmodified image formats. The storage space for all image sequences is almost half the size of standard solutions. This is made possible thanks to the real picture format saving which enables fast sequence search runs.

Lano Photonics Economical Line Scan Camera

Color | Monochrome | Frame rate 120FPSThe Lano Photonics Economical Line Scan Camera is a cost-effective option designed for precision industry testing in non-high-end applications. This camera offers several standout features and capabilities that make it suitable for a range of industrial automation tasks.

The camera supports various conventional ISP (Image Signal Processing) functions, allowing for image enhancement and correction. It also supports true color SCS (Sensor Color Space) color correction, ensuring accurate color representation in captured images. Additionally, the camera supports black and white camera TDI (Time Delay Integration), enabling efficient image acquisition in low-light or high-speed scenarios. Bright/dark field correction, lens shadow correction, distortion correction, and light source uniformity correction further enhance image quality and accuracy.

With a built-in large-capacity frame buffer, the camera ensures safe and reliable data verification and repair technology. This feature guarantees smooth data transmission and reduces the risk of data loss or corruption. The camera's wide working voltage range of 9-52V and low power consumption design contribute to its versatility and adaptability to various industrial automation setups.

The software compatibility of the Lano Photonics Economical Line Scan Camera is another noteworthy aspect. It supports GigE Vision, a widely adopted interface standard for industrial cameras, ensuring seamless integration with compatible software systems. Moreover, the camera is compatible with the GenICam protocol, which provides a standardized way to control and configure imaging devices. This compatibility simplifies system integration, enabling efficient data processing and analysis.

Lano Photonics LANO-AF500-24GC

ColorThe LANO-AF500-24GC is a second generation industrial camera designed with excellent power consumption in mind. Its new generation appearance structure also features higher installation accuracy, making it a versatile and reliable solution for various industrial imaging applications.

The PRO version of the LANO-AF500-24GC comes embedded with lossless compression, noise reduction, super color palette, and user-defined key functions, providing rich features that enable high-quality imaging and customization for specific use cases.

This industrial camera also features a Gigabit network interface with a maximum transmission distance of up to 100m without the need for a relay. It is compatible with GigE Vision V2.0 protocol and GenlCam standard, allowing for seamless connection with third-party software.

The LANO-AF500-24GC has CE, FCC, and RoHS certification, ensuring compliance with industry standards and regulations. Additionally, its compact size of 29 mm × 29 mm × 31.5 mm makes it easy to integrate into various industrial systems while maintaining high-quality imaging performance.

Lano Photonics LANO-AN230-40GC

ColorThe LANO-AN230-40GC industrial camera is equipped with powerful features that make it an ideal solution for a variety of applications. Its second-generation design and excellent power consumption make it a reliable and efficient option for industrial use.

The camera's new generation appearance structure design supports four-side installation and offers higher installation accuracy, ensuring ease of use and precision. Additionally, the PRO version comes with lossless compression, noise reduction, super color palette, user-defined key, and other rich features that improve the quality and functionality of the camera.

The LANO-AN230-40GC also features a gigabit network interface, allowing for a maximum transmission distance of up to 100m without the need for a relay. It is compatible with GigE Vision V2.0 protocol and GenlCam standard, enabling seamless connection to third-party software.

Furthermore, the camera conforms to CE, FCC, and RoHS certification standards, ensuring that it meets the necessary safety and environmental requirements. Its compact dimensions of 29mm x 29mm x 31.5m make it a space-saving option for industrial environments.

In summary, the LANO-AN230-40GC is a powerful and versatile industrial camera that can be used in a wide range of applications, including machine vision, factory automation, and quality control.

Alkeria CO4K-M

Monochrome | Frame rate 92FPSAlkeria's CO4K-M camera is an excellent option for those applications where one USB3 interface is sufficient. The CELERA One camera series provides the same level of quality, flexibility, and performance as the CELERA cameras, but in a compact and convenient package that is suitable for a wide range of applications, including automated optical inspection, high-performance sorting systems, industrial metrology, microscopy, medical diagnostics, and machine vision.

One of the advantages of CELERA One cameras is that they can be powered directly by the USB3 bus, eliminating the need for external power adapters. This makes them a cost-effective solution while still providing top speed performance.

CELERA One cameras also offer a versatile I/O interface, which enables users to control external devices such as strobe lights and encoders. It has two input lines with direct encoder interface, two output lines, and one input/output (RS422, RS644 LVDS, LVTTL). The multipurpose I/O connector provides user I/O, line/frame triggering, and direct encoder interface.

CELERA One cameras are equipped with powerful on-board image processing capabilities, allowing users to perform on-line, user-controlled image processing. This includes 8 AOI, independent LUTs, gamma correction, white balance, brightness, contrast, sharpness, saturation, and hue. The control sequencing mechanism can apply up to 64 different video settings to a chain of subsequent frames.

For developers, an easy-to-use set of software API is available that supports all major programming languages, such as Python, C#, VB, and C++ in Visual Studio or QT environment. Alkeria's Software Development Kit provided with CELERA One cameras is fully compatible with Cognex VisionPro, MVTech Halcon, NI LabView, and other major machine vision software for industrial applications.

CELERA One comes with a standard C-mount lens adapter, and other accessories are available upon request, such as F-mount adapter, shielded I/O cable, and industrial grade USB3 cables.

Lano Photonics AN Series Medium & high-speed Area Scan Camera-60MM

Color | Monochrome | Frame rate 158.8FPSThe Lano Photonics AN Series Medium & High-Speed Area Scan Camera-60MM is an advanced camera designed specifically for industrial automation applications. This camera offers a range of standout features, capabilities, and specialized specifications, making it a unique option for various industrial settings.

Featuring a 4 Lane CoaXPress interface, the Lano Photonics AN Series Camera-60MM enables high-speed data transfer between the camera and the connected system. It supports POCXP (Power over CoaXPress) and CXP-10 (CoaXPress 10 Gbps) standards, ensuring fast and efficient image acquisition and transmission. With a maximum frame rate of 159 frames per second, this camera excels in applications that require real-time monitoring and high-speed inspection.

The camera's resolution options are particularly impressive, ranging from 16.2 megapixels to 24.6 megapixels. This flexibility allows users to capture highly detailed and precise images, enabling accurate analysis and inspection in industrial automation processes. The high resolution is especially beneficial in applications that require intricate visual examination, such as electronic component inspection or product quality control.

In terms of design, the Lano Photonics AN Series Camera-60MM features a size of 60mm x 60mm, providing a compact form factor that facilitates easy integration into existing systems and setups. This compact size ensures versatility and compatibility with various industrial automation environments without compromising on performance. Furthermore, the camera's ultra-low power consumption and fanless design contribute to its efficiency and reliability, even in demanding industrial conditions.

The camera's automatic optical calibration is another standout feature, ensuring consistently high image quality. This calibration process eliminates the need for manual adjustments, simplifying setup and maintenance while guaranteeing optimal imaging performance. The camera consistently delivers accurate and reliable results, making it suitable for applications that require precise measurements or visual inspections.

The Lano Photonics AN Series Camera-60MM also possesses specialized specifications that make it an excellent choice for industrial automation. It offers tolerance for extreme temperatures, allowing it to withstand harsh industrial environments where temperature fluctuations are common. This durability ensures the camera's reliability and longevity, making it suitable for use in demanding conditions.

Additionally, the camera is compatible with specific software systems commonly used in industrial automation. This compatibility enables seamless integration with existing automation workflows, facilitating efficient data processing and analysis. By leveraging the camera's capabilities within established software systems, users can enhance productivity, streamline processes, and achieve optimal results in their industrial automation applications.

In conclusion, the Lano Photonics AN Series Medium & High-Speed Area Scan Camera-60MM is a powerful and versatile camera designed for industrial automation. With its 4 Lane CoaXPress interface, high-resolution options, compact size, low power consumption, automatic optical calibration, and compatibility with software systems, this camera offers exceptional image quality, efficiency, and reliability in a wide range of industrial automation applications.

Alkeria CO12S-M

Monochrome | Frame rate 23FPSAlkeria's CO12S-M camera is an excellent option for those applications where one USB3 interface is sufficient. The CELERA One camera series provides the same level of quality, flexibility, and performance as the CELERA cameras, but in a compact and convenient package that is suitable for a wide range of applications, including automated optical inspection, high-performance sorting systems, industrial metrology, microscopy, medical diagnostics, and machine vision.

One of the advantages of CELERA One cameras is that they can be powered directly by the USB3 bus, eliminating the need for external power adapters. This makes them a cost-effective solution while still providing top speed performance.

CELERA One cameras also offer a versatile I/O interface, which enables users to control external devices such as strobe lights and encoders. It has two input lines with direct encoder interface, two output lines, and one input/output (RS422, RS644 LVDS, LVTTL). The multipurpose I/O connector provides user I/O, line/frame triggering, and direct encoder interface.

CELERA One cameras are equipped with powerful on-board image processing capabilities, allowing users to perform on-line, user-controlled image processing. This includes 8 AOI, independent LUTs, gamma correction, white balance, brightness, contrast, sharpness, saturation, and hue. The control sequencing mechanism can apply up to 64 different video settings to a chain of subsequent frames.

For developers, an easy-to-use set of software API is available that supports all major programming languages, such as Python, C#, VB, and C++ in Visual Studio or QT environment. Alkeria's Software Development Kit provided with CELERA One cameras is fully compatible with Cognex VisionPro, MVTech Halcon, NI LabView, and other major machine vision software for industrial applications.

CELERA One comes with a standard C-mount lens adapter, and other accessories are available upon request, such as F-mount adapter, shielded I/O cable, and industrial grade USB3 cables.