Pickit 3D Bin Picking Billets Specifications

Ranked Nr. 144 of 97 3D Vision Systems

Do you still rely on noisy and costly mechanical – or manual - billet feeding?

Time to bring your forge to the 21st century with 3D vision robot automation from Pickit3D!

How your forge benefits from 3D vision automation:

1. Avoid high maintenance costs of feeders

2. Use space better and reduce noise in the factory

3. Flexibly adjust or change billet types without major interventions

4. Reduce downtime with reliable and safe billet picking

5. Introduce smaller production runs cost-effectively

Choose your model:

Depalletizing Boxes or Bags

Bin Picking Billets

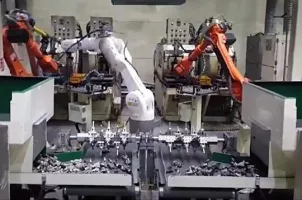

Bin Picking - Random Parts

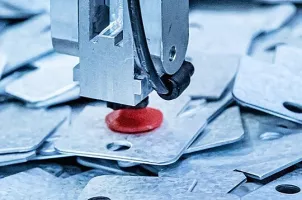

Bin Picking Sheet Metal

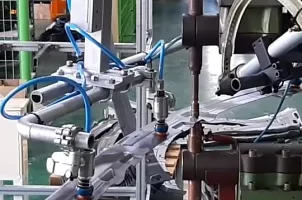

Assembly

Surface Treatment & Dispensing

| Industry |

|

| Application |

|