Qviro AUBO i10 SwitchWeld Station Specifications

Ranked Nr. 28 of 61 Turnkey Robot Solutions

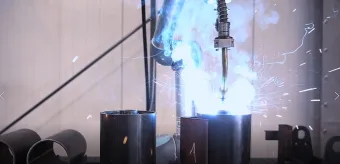

The AUBO i10 SwitchWeld Station is a cobot-based welding solution tailored for users with limited experience in robotic welding. It leverages a simplified control interface, particularly the SwitchWeld Navigator Puck™, which enables precise robot positioning without the need for complex programming. The puck-based control system allows users to set up and execute welding tasks through just three buttons, streamlining the learning curve and increasing accessibility for operators. The system’s software further enhances efficiency by suggesting appropriate weld schedules based on project specifications, minimizing the need for manual adjustments.

With a payload capacity of 10 kg and a reach of 1350 mm, the AUBO i10 cobot in the SwitchWeld system is suited for medium-duty welding applications. Its repeatability of 0.03 mm ensures precision in tasks requiring consistent weld quality. The system is designed to integrate easily with existing welding tools and power supplies, allowing users to continue utilizing familiar equipment without additional investments in new hardware. The hardware bundle, including the necessary cables, mounting tools, and safety features, ensures that the cobot can be operational out of the box.

- No programming required: It only takes three buttons to program an entire welding project with the SwitchWeld Navigator puck.

- Easy to Understand User Interface: The SwitchWeld UI was designed in a way that is intuitive and simple for anyone to understand – regardless of robotic experience or training.

The primary applications for the AUBO i10 SwitchWeld Station include small- to medium-sized welding tasks in industries such as metal fabrication, automotive, and machinery production. Its ease of use, combined with a customizable setup, makes it ideal for operations looking to automate their welding processes without overhauling their existing workflows or investing in proprietary equipment.

Every SwitchWeld cobot welding bundle comes standard with all you’ll need to start welding, including:

- AUBO i-Series Cobot (i10 Cobot for this solution)

- AUBO Control Box

- AUBO Teach Pendant

- AUBO Cobot Cables and Adapters

- ATTC Lightning, Air Cooled MIG Welding Torch

- Welding Torch Mount

- SwitchWeld Navigator Puck & Cable

- SwitchWeld Mounting Tophat

- SwitchWeld 6 Depth of Field Joystick

- SwitchWeld Plugin Box & Labeled Wires

- SwitchWeld Safe Operation Console

- Safe Operation Console Connection Cables

- SwitchWeld Safety Whip Clamps

- SwitchWeld Welding Power Supply Connection Cable & Adapter

- SwitchWeld EZ Mount Base Plate

- SwitchWeld Installation Instructions

- SwitchWeld Software USB Hub & Flash Drive

- WiFi Hub for Software Installer

| NAME | VALUE | UNIT |

|---|---|---|

| Robot Max Payload | 10 | kg |

| Cobot max reach | 1350 | mm |

| Repeatability | 0.03 | mm |

| Mounting base footprint | Ø220 | mm |