Qviro Palletizer FANUC CRX10AiL + Lift Column Alternatives & Competitors

Ranked Nr. 27 of 61 Turnkey Robot Solutions

Top 10 Palletizer FANUC CRX10AiL + Lift Column Alternatives

- Qviro AUBO i20 Palletizer Station

- Qviro Palletizer with CRX25iA, 2 pallet stations, 1 Robotize U24W AMR and 1 charger station

- Qviro Dobot Palletizer with lift column CR20A

- Qviro Palletizer Dobot CR20A + Lift Column

- Qviro Dobot Static Palletizer CR20A

- Qviro Palletizer with 7th axis and one AMR tending 8 pallet stations around

- Onexia PalletizCRX

- Unchained Robotics MalocherBot Palletizing

Qviro AUBO i20 Palletizer Station

The AUBO i20 Palletizer Station is designed as a compact and efficient palletizing solution, equipped with a robotic arm capable of handling loads up to 20 kg. It achieves a maximum stacking height of 2100 mm, optimizing the vertical space in warehouses and ensuring efficient use of available storage. With a cycling rate of 6 picks per minute, the system is ideal for medium to high-volume operations that require reliable and consistent palletizing performance.

This station comes preconfigured and prewired, allowing for rapid deployment with minimal setup, eliminating the need for specialized programming or operator intervention. Its small footprint ensures it fits seamlessly into existing production environments without requiring significant floor space. The dual-pallet configuration allows for greater flexibility and reduces downtime during pallet changeovers.

Specs:

| NAME | VALUE | UNIT |

|---|---|---|

| Width | 1428 | mm |

| Height | 1250 | mm |

| Stacking Height | 2100 | mm |

| Cycling Time | 6 | picks/min |

| Length | 1640 | mm |

| Lifting Capacity | 20 | kg |

| Cobot max reach | 1650 | mm |

| Max. Pallet size | L:1200 mm x W: 1200 mm | mm |

| Repeatability | 0.1 | mm |

Qviro Palletizer with CRX25iA, 2 pallet stations, 1 Robotize U24W AMR and 1 charger station

The collaborative robotic palletizer features a CRX25iA arm with a load capacity of up to 30 kg, designed for efficient palletizing operations. It organizes products and boxes onto pallets for shipping at a stacking height of 2200 mm and a cycling time of 8 picks per minute. This system is particularly advantageous for facilities aiming to automate their palletizing processes while maintaining flexibility and ease of use.

A key differentiator of this solution is its complete autonomy. The included Robotize U24W AMR, with a load capacity of 1200 kg, eliminates the need for human intervention in the pallet handling process. It autonomously removes loaded pallets from the pallet stations and repositions empty pallets, ensuring a continuous workflow without the use of forklifts. This level of automation enhances operational efficiency and reduces labor costs.

Additionally, the system is equipped with a dedicated charging station, allowing the AMR to autonomously recharge as needed. This feature ensures minimal downtime and maximizes productivity in warehouse environments. The palletizer can be customized to accommodate specific requirements, making it suitable for a variety of industries, including food and beverage, consumer goods, and logistics.

| NAME | VALUE | UNIT |

|---|---|---|

| Max Payload | 30 | kg |

| Length | 4950 | mm |

| Width | 4400 | mm |

| Height | 2300 | mm |

| Stacking Height | 2200 | mm |

| Cycling Time | 8 | picks/min |

| Pallet Types | US |

Qviro Dobot Palletizer with lift column CR20A

The Dobot Palletizer with Lift Column CR20A is designed to optimize space and efficiency in palletizing operations. With a 20 kg payload capacity and a stacking height of up to 2100 mm, it enables better use of vertical space in warehouses. The system can handle up to 8 picks per minute, making it suitable for medium-speed palletizing tasks that require precision and reliability.

Equipped with a lift column, the system can adjust to different pallet heights, improving flexibility for various stacking configurations. The palletizer features two LiDAR sensors for obstacle detection and pallet alignment, enhancing its safety and operational accuracy. It also includes an emergency stop and pallet sensors, ensuring the system meets safety standards while minimizing the risk of downtime.

Ideal for industries such as logistics and warehousing, the CR20A with Lift Column is capable of managing two pallets simultaneously, positioned on either side of the robotic arm. This configuration improves workflow efficiency by reducing cycle times, making it a practical solution for facilities with moderate to high throughput needs.

| NAME | VALUE | UNIT |

|---|---|---|

| Lifting Capacity | 20 | kg |

| Stacking Height | 2100 | mm |

| Length | 2260 | mm |

| Height | 1430 | mm |

| Cycling Time | 8 | picks/min |

| Width | 1300 | mm |

Qviro Palletizer Dobot CR20A + Lift Column

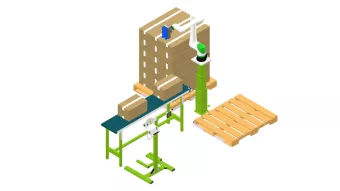

The Palletizer Dobot CR20A with Lift Column is designed for high-performance palletizing tasks, featuring a 20 kg payload capacity and the ability to stack loads up to 2100 mm in height. Its compact design allows it to operate efficiently in warehouse environments with limited space, making it suitable for optimizing storage and palletizing operations. The CR20A robotic arm ensures precise and consistent operation, handling up to 10 picks per minute, making it ideal for medium- to high-speed palletizing applications.

With the addition of the lift column, the palletizer can reach extended pallet heights, enhancing its versatility for handling larger loads or stacking operations. The system is configured to work with two pallets placed on either side of the lift pedestal, improving workflow efficiency. A feeding conveyor system is included to automate material handling and streamline operations, reducing manual intervention.

This palletizing solution offers customization options in terms of dimensions, configurations, and quantities, allowing it to be tailored to specific warehouse or manufacturing needs. The adaptability of the system makes it suitable for industries requiring flexibility in palletizing tasks, such as logistics, manufacturing, and distribution centers.

| NAME | VALUE | UNIT |

|---|---|---|

| Cycling Time | 10 | picks/min |

| Length | 6464 | mm |

| Width | 2703 | mm |

| Height | 2300 | mm |

| Lifting Capacity | 20 | kg |

| Stacking Height | 3200 | mm |

Qviro Dobot Static Palletizer CR20A

The Dobot Static Palletizer CR20A is designed for efficient palletizing with a 20 kg payload and stacking heights of up to 1500 mm. Its stationary pedestal design supports a robust and stable operation, making it suitable for palletizing tasks in warehouses where space optimization and consistent handling are essential. With a cycle time of up to 8 picks per minute, it balances speed and precision in medium-duty palletizing applications.

Equipped with two LiDAR sensors, the palletizer ensures safe and accurate operation by detecting obstacles and improving spatial awareness. It also features an emergency stop and pallet sensors for enhanced safety and functionality, allowing for smooth, automated pallet handling. This system can manage two pallets on either side of the stationary pedestal, improving workflow efficiency.

The CR20A palletizer is ideal for industries requiring mid-range palletizing solutions, such as logistics and manufacturing. Its safety features and efficient design make it well-suited for environments where automation needs to coexist with human workers and where space and cycle time constraints must be balanced.

| NAME | VALUE | UNIT |

|---|---|---|

| Lifting Capacity | 20 | kg |

| Stacking Height | 3100 | mm |

| Cycling Time | 8 | picks/min |

| Length | 2260 | mm |

| Width | 1300 | mm |

| Height | 1430 | mm |

Qviro Palletizer with 7th axis and one AMR tending 8 pallet stations around

The FANUC M410iB-140H industrial palletizer is designed for high-capacity operations, featuring a payload of up to 140 kg. It is mounted on a Gudel Track Motion Floor (TMF-3), which provides an additional axis of movement, allowing it to tend to eight pallet stations efficiently. With a maximum stacking height of 3200 mm, the robot can achieve up to 1900 palletizing cycles per hour, making it one of the fastest palletizing solutions in its class.

This system integrates seamlessly with a McMaster conveyor for product feeding, ensuring a continuous supply to the palletizer. After the palletizing process, an autonomous mobile robot (AMR) transports the finished pallets to subsequent processes, enhancing overall logistics efficiency. The AMR features self-charging capabilities with dedicated power stations, which minimizes downtime and optimizes operational workflows.

Customizable in terms of dimensions and configurations, this palletizing solution can be tailored to meet specific industry requirements, making it suitable for diverse applications, including manufacturing, food and beverage, and consumer goods. Its robust design and high throughput make it ideal for environments where efficiency and scalability are critical.

| NAME | VALUE | UNIT |

|---|---|---|

| Length | 20000 | mm |

| Width | 10560 | mm |

| Height | 3200 | mm |

| Max. Speed Robot | up to 1900 palletizing cycles | cycles/h |

| Max. Speed Track Motion Floor | 120-150 | m/min |

| Stacking Height | 3200 | mm |

| Axes | 6 | |

| Lifting Capacity | 140 | kg |

| Track Motion Floor Payload | 20000-40000 | N |

Onexia PalletizCRX

Manufactured by ONExia, a FANUC Authorized Systems Integrator specializing in collaborative robots, the PalletizCRX is a turn-key palletizer using the FANUC CRX-10iA/L cobot.

By using a FANUC cobot, the PalletizCRX requires no physical guarding to operate within the work cell drastically decreasing the footprint of adding automation.

The PalletizCRX is a fully collaborative solution for FANUC users looking for a flexible alternative to standard industrial palletizing robots.

PalletizCRX Features:

The PalletizCRX requires no programming and can be deployed to an existing packaging line in under an hour.

Minimal footprint - no guarding or caging needed

Portable - easily moved with a forklift or pallet jack

Collaborative - full rating for entire system

Quick deployment - requires a standard outlet and an air line

Continuous operation - palletize to both sides

Unchained Robotics MalocherBot Palletizing

The Unchained Robotics MalocherBot Palletizing system is a modular, turnkey solution designed for efficient and flexible palletizing tasks. With a robust structure, it can handle up to 20 kg payloads and stack up to 12 packages per minute, or 36 packages with multigrip functionality. The system’s modular design allows for quick setup and easy reconfiguration, making it adaptable to changing production needs.

This system integrates seamlessly with YASKAWA robots, offering a reach of 1,800 mm and a stacking height of 1.8 meters. The control unit, which includes the LUNA software, enables operators to configure the system quickly by inputting package sizes, palletizing patterns, and other parameters through an intuitive interface. This results in a setup time of less than 24 hours from delivery to operation.

MalocherBot Palletizing is particularly suitable for industries where rapid deployment and versatility are crucial, such as logistics, consumer goods, and food packaging. Its vacuum-based gripping method ensures compatibility with various materials, including all types of cardboard boxes and flat, non-porous materials, making it a reliable solution for diverse palletizing requirements.