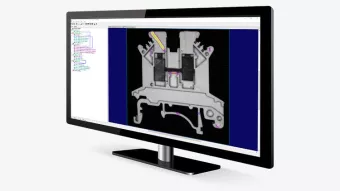

RoboDK Calibration Specifications

Ranked Nr. 49 of 85 Robot Software

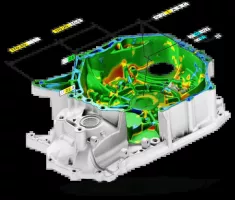

Robot calibration is the process of identifying the real geometrical parameters in the kinematic structure of an industrial robot, such as the relative position of joint links in the robot. Robot calibration improves accuracy of robots programmed offline (Offline Programming).

Robot calibration can be accomplished with RoboDK in less than 20 minutes. Easily generate robot programs offline once with RoboDK's offline programming tools.

RoboDK calibration key features

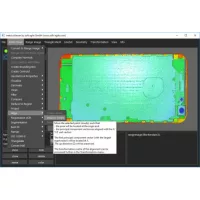

- Fully Automated generation of measurements and acquisition

- Fully Automated collision avoidance

- RoboDK API allows you to customize the calibration workspace

- Works with any 3D or 6D measurement system

- Calibrate any robot with up to 30 parameters

- Robot accuracy can be improved by a factor of 10

- Over 500 robots from 50 manufacturers supported

- Easily run ISO9283 performance tests

- Compare accuracy with ballbar accuracy tests

- No need to filter milling programs with RoboDK

| Software type |

|

| Type |

|

| Extra info | Robot calibration steps: Base calibration (6-20 measurements) / Tool calibration (6-20 measurements) / Robot calibration (40-100 measurements) / Validation (40-100 measurements) / |